Narrow pitch connectors

A35US

with power terminal (0.35mm pitch)

–2–

ACCTB78E 201510-T

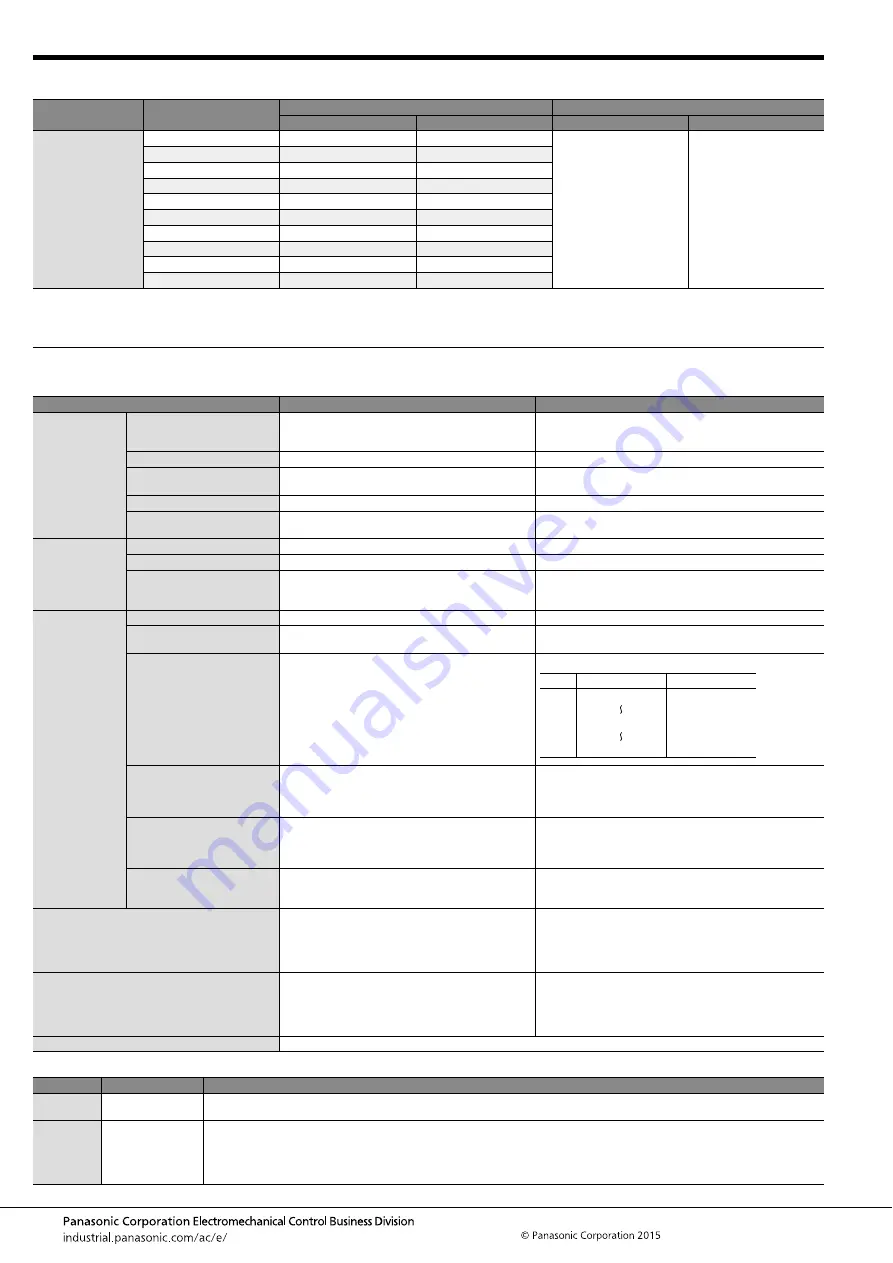

PRODUCT TYPES

Notes: 1. Order unit:

For volume production: 1-inner carton (1-reel) units

For samples, please contact our sales office.

2. Please contact us for connectors having a number of pins other than those listed above.

SPECIFICATIONS

1. Characteristics

2. Material and surface treatment

Mated height

Number of pins

Part number

Packing

Socket

Header

Inner carton (1-reel)

Outer carton

0.6mm

10

AXG7100J7

AXG8100J4

10,000 pieces

20,000 pieces

12

AXG7120J7

AXG8120J4

16

AXG7160J7

AXG8160J4

20

AXG7200J7

AXG8200J4

24

AXG7240J7

AXG8240J4

30

AXG7300J7

AXG8300J4

34

AXG7340J7

AXG8340J4

40

AXG7400J7

AXG8400J4

50

AXG7500J7

AXG8500J4

60

AXG7600J7

AXG8600J4

Item

Specifications

Conditions

Electrical

characteristics

Rated current

3.0A/pin contact (power terminal)

0.30A/pin contact (signal terminal): Max. 5 A at total

pin contacts

Rated voltage

60V AC/DC

Breakdown voltage

150V AC for 1 min.

No short-circuiting or damage at a detection current of 1 mA

when the specified voltage is applied for one minute.

Insulation resistance

Min. 1,000M

Ω

(initial)

Using 250V DC megger (applied for 1 min.)

Contact resistance

Max. 30m

Ω

(power terminal)

Max. 90m

Ω

(signal terminal)

Based on the contact resistance measurement method

specified by JIS C 5402.

Mechanical

characteristics

Composite insertion force

1.300N/pin contacts

×

pin contacts

Composite removal force

0.165N/pin contacts

×

pin contacts

Contact holding force

(Socket signal terminal,

Header power terminal)

Min. 0.20N/pin contacts

Measuring the maximum force.

As the contact is axially pull out.

Environmental

characteristics

Ambient temperature

–55

°

C to +85

°

C

No freezing at low temperatures. No dew condensation.

Storage temperature

–55

°

C to +85

°

C (product only)

–40

°

C to +50

°

C (emboss packing)

No freezing at low temperatures. No dew condensation.

Thermal shock resistance

(header and socket mated)

5 cycles,

insulation resistance min. 100M

Ω

,

contact resistance max. 30m

Ω

(power terminal)

max. 90m

Ω

(signal terminal)

Conformed to MIL-STD-202F, method 107G

Humidity resistance

(header and socket mated)

120 hours,

insulation resistance min. 100M

Ω

,

contact resistance max. 30m

Ω

(power terminal)

max. 90m

Ω

(signal terminal)

Conformed to IEC60068-2-78

Bath temperature 40

±

2

°

C,

humidity 90 to 95% R.H.

Saltwater spray resistance

(header and socket mated)

24 hours,

insulation resistance min. 100M

Ω

,

contact resistance max. 30m

Ω

(power terminal)

max. 90m

Ω

(signal terminal)

Conformed to IEC60068-2-11

Bath temperature 35

±

2

°

C,

saltwater concentration 5

±

1%

H

2

S resistance

(header and socket mated)

48 hours,

contact resistance max. 30m

Ω

(power terminal)

max. 90m

Ω

(signal terminal)

Bath temperature 40

±

2

°

C, gas concentration 3

±

1 ppm,

humidity 75 to 80% R.H.

Insertion and removal life

Mechanical life: 30 times

Contact resistance max. 30m

Ω

(power terminal)

max. 90m

Ω

(signal terminal)

Composite removal

force 0.165N/pin contacts

×

pin contacts

Repeated insertion and removal speed of max. 200 times/

hours

Soldering heat resistance

The initial specification must be satisfied electrically

and mechanically

Infrared reflow soldering: Peak temperature: 260

°

C or less

(on the surface of the PC board

around the connector terminals)

Soldering iron: 300

°

C within 5 sec.

350

°

C within 3 sec.

Unit weight

60 pin contacts: Socket 0.02g Header 0.01g

Part name

Material

Surface treatment

Molded

portion

LCP resin

(UL94V-0)

—

Contact and

Post

Copper alloy

Contact portion: Base: Ni plating, Surface: Au plating

Terminal portion: Base: Ni plating, Surface: Au plating (except the terminal tips)

The terminals close to the portion to be soldered have nickel barriers (exposed nickel portions).

Power terminals: Sockets: Base: Ni plating, Surface: Au plating (except the terminal tips)

Headers: Base: Ni plating, Surface: Au plating

Order Temperature (

°

C)

Time (minutes)

1

2

3

4

–55

85

–55

0

−

3

30

Max. 5

30

Max. 5

+

3

0

0

−

3