Notes on Using Narrow pitch Connectors/Stacking Connectors for High Current

–8–

ACCTB48E 201412-T

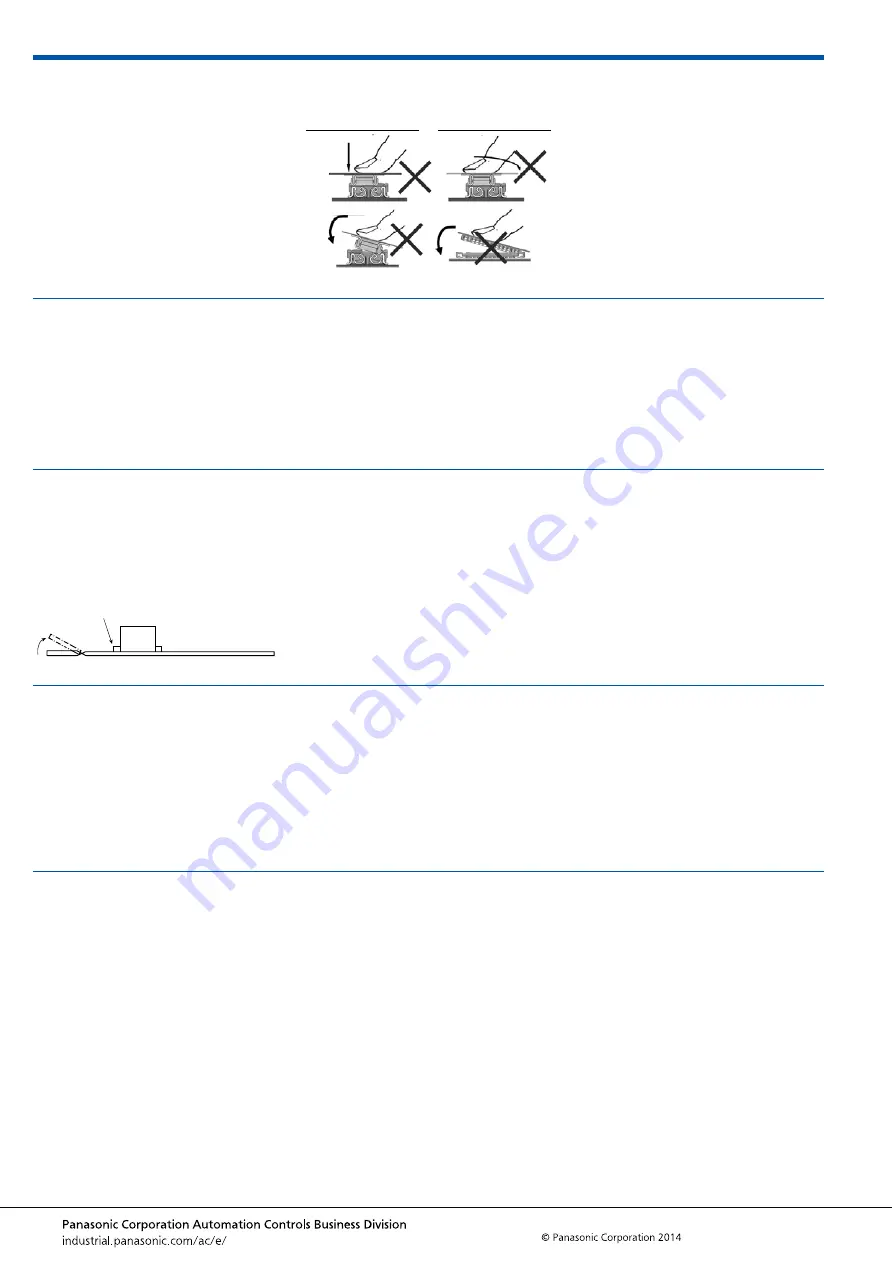

Precautions for mating

Cleaning flux from PC board

Handling the PC board

Storage of connectors

Other Notes

This product is designed with ease of

handling. However, in order to prevent the

deformation or damage of contacts and

molding, take care and do not mate the

connectors as shown below.

Strongly pressed and twisted

Tilted mating

Press-fitting while the mating

inlets of the socket and

header are not matched.

1) There is no need to clean this product.

If cleaning it, pay attention to the

following points to prevent the negative

effect to the product

2) Keep the cleaning solvent clean and

prevent the connector contacts from

contamination.

3) Some cleaning solvents are strong and

they may dissolve the molded part and

characters, so pure water passed liquid

solvent is recommended

■

Handling the PC board after

mounting the connector

When cutting or bending the PC board

after mounting the connector, be careful

that the soldered sections are subjected

to excessive force.

The soldered areas should not be subjected to force.

1) To prevent problems from voids or air

pockets due to heat of reflow soldering,

avoid storing the connectors in areas of

high humidity.

2) Depending on the connector type, the

color of the connector may vary from

connector to connector depending on

when it is produced.

Some connectors may change color

slightly if subjected to ultraviolet rays

during storage. This is normal and will not

affect the operation of the connector.

3) When storing the connectors with the

PC boards assembled and components

alreeady set, be careful not to stack them

up so the connectors are subjected to

excessive forces.

4) Avoid storing the connectors in

locations with excessive dust. The dust

may accumulate and cause improper

connections at the contact surfaces.

1) Do not remove or insert the electrified

connector (in the state of carrying current

or applying voltage).

2) Dropping of the products or rough

mishandling may bend or damage the

terminals and possibly hinder proper

reflow soldering.

3) Before soldering, try not to insert or

remove the connector more than

absolutely necessary.

4) When coating the PC board after

soldering the connector to prevent the

deterioration of insulation, perform the

coating in such a way so that the coating

does not get on the connector.

5) There may be variations in the colors

of products from different production lots.

This is normal.

6) The connectors are not meant to be

used for switching.

7) Precautions for usage environment

and storage environment.

8) Product failures due to condensation

are not covered by warranty.