Page 1-25

REGULAR

MAINTENANCE

1

Check Every 140 Hours (Once a Week)

1-4-2

Cleaning and Lubricating the Tape Feeder Table

Clean and lubricate the tape feeder table.

∗

For DU/DHU specifications, it is necessary to remove the feeder base cover for the maintenance.

1-2-3 Setting and Removing the Feeder Base Cover (Only for DU/DHU Specifications)

1.

Turn OFF the servo switch.

2.

Open the safety cover.

3.

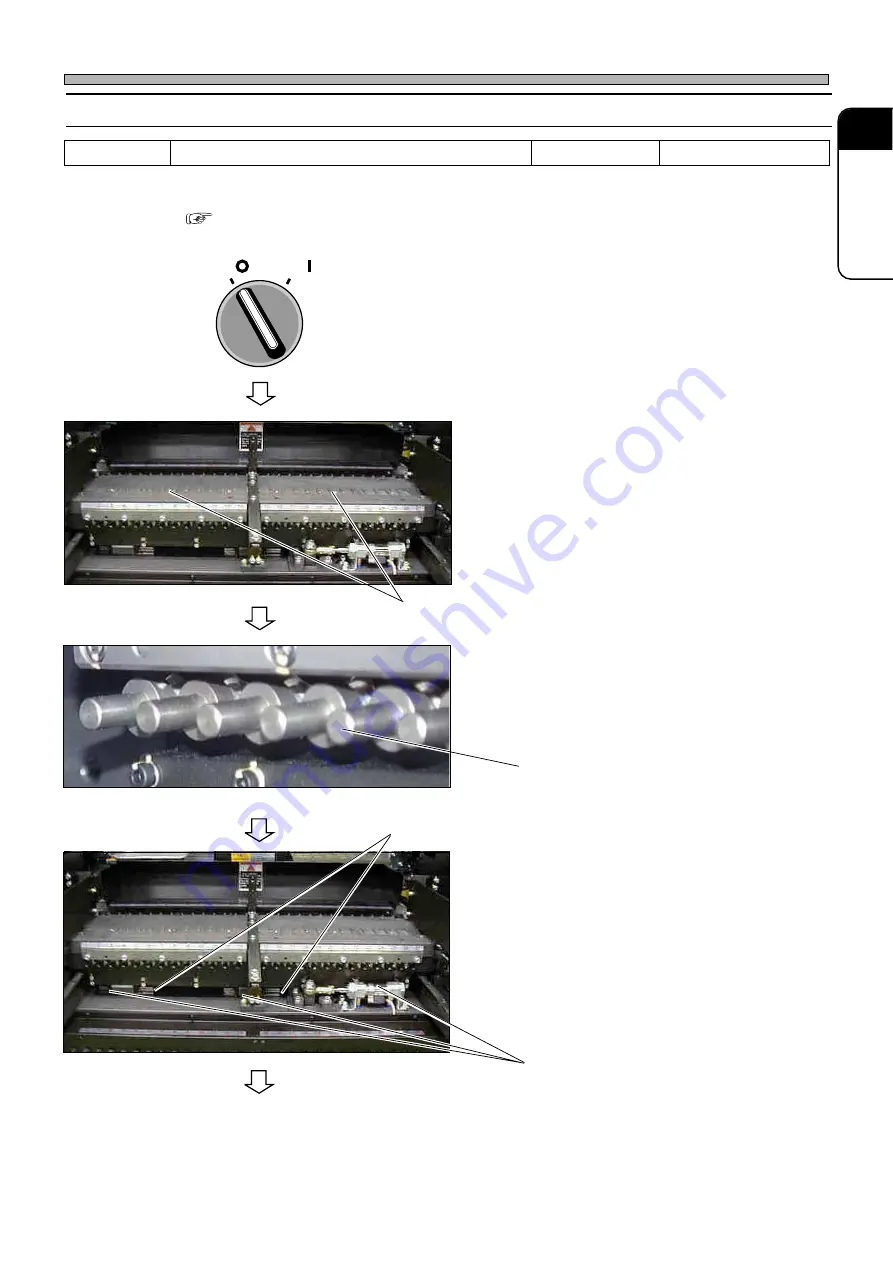

Clean the surroundings of the tape

feeder tables with the vacuum cleaner

or cleaning brush.

∗

If chip components have dropped on the tape

feeder tables, the tape feeder ski will be

damaged and the pick-up position may be

dislocated. And, what’s worse, pick-up errors

can be increased. Before changing production

models or the tape feeder parts, be sure to

clean there.

4.

Ensure that there is no damage to the

tip of the projection rod.

5.

Apply grease to the linear-bearing rail

grooves for the double tape feeder.

∗

Only when the optional double tape feeder is

installed, carry out this operation.

To the next page

444C-E-MMA01-A04-04

Tools

Required time

5 minutes

Cloth

OFF ( ) ON ( )

SERVO

444C-509P

444C-409P

Projection rod

Linear bearing

Tape feeder table

444C-509P

Rail groove