Page 1-61

REGULAR

MAINTENANCE

1

1-5

Check Every 560 Hours (Once a Month)

1-5-1

Cleaning the Lubricating the Transfer Head

Clean and lubricate the nozzle shaft support bearing and check the vacuum pressure at the nozzle

tip. Dirt on the nozzle shaft support bearing may cause wrong operation and pickup. Leakage in the

air pass will also cause wrong pickup.

∗

For DU/DHU specifications, it is necessary to remove the feeder base cover for the maintenance.

1-2-3 Setting and Removing the Feeder Base Cover (Only for DU/DHU Specifications)

1.

Cleaning and lubricating the nozzle shaft support bearing

1.

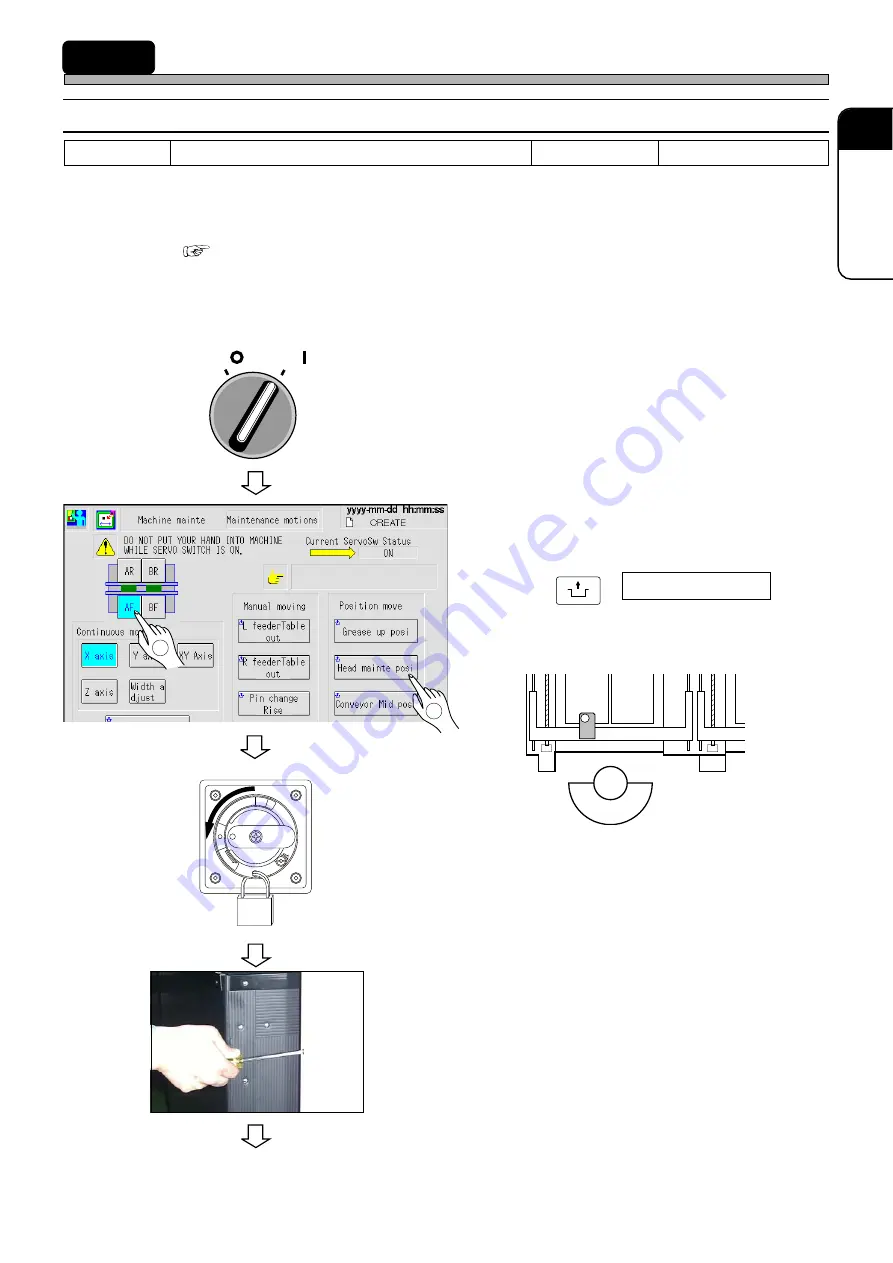

Ensure that the safety cover is

closed, and turn on the servo switch.

2.

Select the operation table.

3.

Press

UNLOCK

+ Head mainte posi .

•

The transfer head moves to the maintenance

position.

4.

Turn OFF the power.

∗

Lock the main switch. A worker should carry

the key. (DU/DHU only)

5.

Open the cover at the lower right of

the machine rear side.

∗

Remove the screw by using a Philips driver.

To the next page

444C-E-MMA01-A08-04

444C-419E

Tools

Philips driver, cotton bud, syringe, and vacuum gauge

Required time

30 minutes

2

1

OFF ( ) ON ( )

SERVO

REL

EA

SE

TR

IP

O

F

F

ON

RE

S

E

T

444C-401P

444C-457E

444C-EEn-MpMmMm-011