36

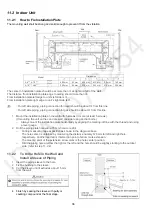

11.2 Indoor Unit

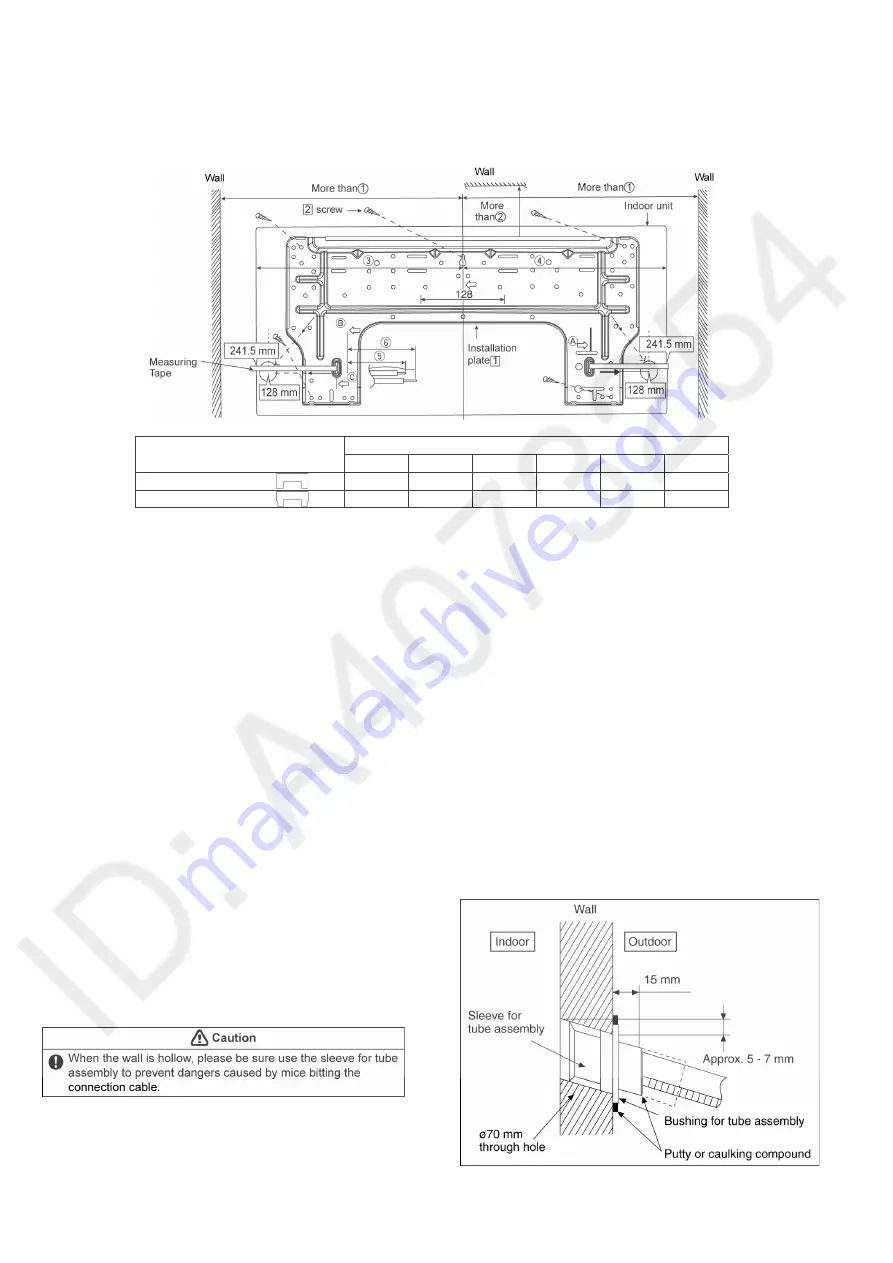

11.2.1 How to Fix Installation Plate

The mounting wall shall be strong and solid enough to prevent if from the vibration.

Dimension

Model

○

1

○

2

○

3

○

4

○

5

○

6

A9***, A12 ***

490 mm

82 mm

439 mm

432 mm

93 mm

145 mm

A18***, A24***

590 mm

82 mm

539 mm

532 mm

219 mm

269 mm

The center of installation plate should be at more than

c

at right and left of the wall.

The distance from installation plate edge to ceiling should more than

d

.

From installation plate left edge to unit’s left side is

e

.

From installation plate right edge to unit’s right side is

f

.

○

B

: For left side piping, piping connection for liquid should be about

g

from this line.

: For left side piping, piping connection for gas should be about

h

from this line.

1 Mount the installation plate on the wall with 5 screws or more (at least 5 screws).

(If mounting the unit on the concrete wall, consider using anchor bolts.)

o

Always mount the installation plate horizontally by aligning the marking-off line with the thread and using

a level gauge.

2 Drill the piping plate hole with ø70 mm hole-core drill.

o

Putting measuring tape at position as shown in the diagram above.

The hole center is obtained by measuring the distance namely 128 mm for left and right hole

respectively. Another method is intersection point of arrow mark extension.

The meeting point of the extension arrow mark is the hole center position.

o

Drill the piping hole at either the right or the left and the hole should be slightly slanting to the outdoor

side. (refer to step 11.2.2)

11.2.2 To Drill a Hole in the Wall and

Install a Sleeve of Piping

1 Insert the piping sleeve to the hole.

2 Fix the bushing to the sleeve.

3 Cut the sleeve until it extrudes about 15 mm

from the wall.

4 Finish by sealing the sleeve with putty or

caulking compound at the final stage.

Summary of Contents for CS-A12PKD

Page 12: ...12 4 Location of Controls and Components 4 1 Indoor Unit 4 2 Outdoor Unit 4 3 Remote Control...

Page 13: ...13 5 Dimensions 5 1 Indoor Unit 5 1 1 CS A9PKD CS A12PKD...

Page 14: ...14 5 1 2 CS A18PKD CS A24PKD CS A28PKD...

Page 15: ...15 5 2 Outdoor Unit 5 2 1 CU A9PKD 5 2 2 CU A12PKD...

Page 16: ...16 5 2 3 CU A18PKD...

Page 17: ...17 5 2 4 CU A24PKD CU A28PKD...

Page 18: ...18 6 Refrigeration Cycle Diagram 6 1 CS A9PKD CU A9PKD CS A12PKD CU A12PKD...

Page 19: ...19 6 2 CS A18PKD CU A18PKD CS A24PKD CU A24PKD CS A28PKD CU A28PKD...

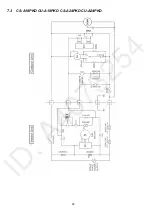

Page 20: ...20 7 Block Diagram 7 1 CS A9PKD CU A9PKD...

Page 21: ...21 7 2 CS A12PKD CU A12PKD...

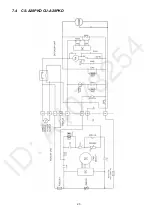

Page 22: ...22 7 3 CS A18PKD CU A18PKD CS A24PKD CU A24PKD...

Page 23: ...23 7 4 CS A28PKD CU A28PKD...

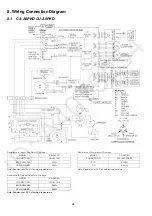

Page 28: ...28 9 Electronic Circuit Diagram 9 1 CS A9PKD CU A9PKD...

Page 29: ...29 9 2 CS A12PKD CU A12PKD...

Page 30: ...30 9 3 CS A18PKD CU A18PKD CS A24PKD CU A24PKD...

Page 31: ...31 9 4 CS A28PKD CU A28PKD...

Page 34: ...34 10 1 4 Comparator Printed Circuit Board 10 1 5 Human Activity Sensor Printed Circuit Board...

Page 40: ...40 11 2 5 Wire Stripping And Connecting Requirement...

Page 48: ...48 12 2 5 Wire Stripping And Connecting Requirement...

Page 87: ...87 Normal Deice Time Diagram Overload Deice Time Diagram...

Page 92: ...92 a Normal Deice Time Diagram b Overload Deice Time Diagram...

Page 98: ...98 Figure 3 Figure 4 17 1 1 3 To remove discharge grille Figure 5...

Page 100: ...100 Figure 9 Figure 10...

Page 104: ...104 Figure 20 Figure 21...

Page 105: ...105 18 Technical Data 18 1 Thermostat Characteristics...