Summary of Contents for CS-A12PKD

Page 12: ...12 4 Location of Controls and Components 4 1 Indoor Unit 4 2 Outdoor Unit 4 3 Remote Control...

Page 13: ...13 5 Dimensions 5 1 Indoor Unit 5 1 1 CS A9PKD CS A12PKD...

Page 14: ...14 5 1 2 CS A18PKD CS A24PKD CS A28PKD...

Page 15: ...15 5 2 Outdoor Unit 5 2 1 CU A9PKD 5 2 2 CU A12PKD...

Page 16: ...16 5 2 3 CU A18PKD...

Page 17: ...17 5 2 4 CU A24PKD CU A28PKD...

Page 18: ...18 6 Refrigeration Cycle Diagram 6 1 CS A9PKD CU A9PKD CS A12PKD CU A12PKD...

Page 19: ...19 6 2 CS A18PKD CU A18PKD CS A24PKD CU A24PKD CS A28PKD CU A28PKD...

Page 20: ...20 7 Block Diagram 7 1 CS A9PKD CU A9PKD...

Page 21: ...21 7 2 CS A12PKD CU A12PKD...

Page 22: ...22 7 3 CS A18PKD CU A18PKD CS A24PKD CU A24PKD...

Page 23: ...23 7 4 CS A28PKD CU A28PKD...

Page 28: ...28 9 Electronic Circuit Diagram 9 1 CS A9PKD CU A9PKD...

Page 29: ...29 9 2 CS A12PKD CU A12PKD...

Page 30: ...30 9 3 CS A18PKD CU A18PKD CS A24PKD CU A24PKD...

Page 31: ...31 9 4 CS A28PKD CU A28PKD...

Page 34: ...34 10 1 4 Comparator Printed Circuit Board 10 1 5 Human Activity Sensor Printed Circuit Board...

Page 40: ...40 11 2 5 Wire Stripping And Connecting Requirement...

Page 48: ...48 12 2 5 Wire Stripping And Connecting Requirement...

Page 87: ...87 Normal Deice Time Diagram Overload Deice Time Diagram...

Page 92: ...92 a Normal Deice Time Diagram b Overload Deice Time Diagram...

Page 98: ...98 Figure 3 Figure 4 17 1 1 3 To remove discharge grille Figure 5...

Page 100: ...100 Figure 9 Figure 10...

Page 104: ...104 Figure 20 Figure 21...

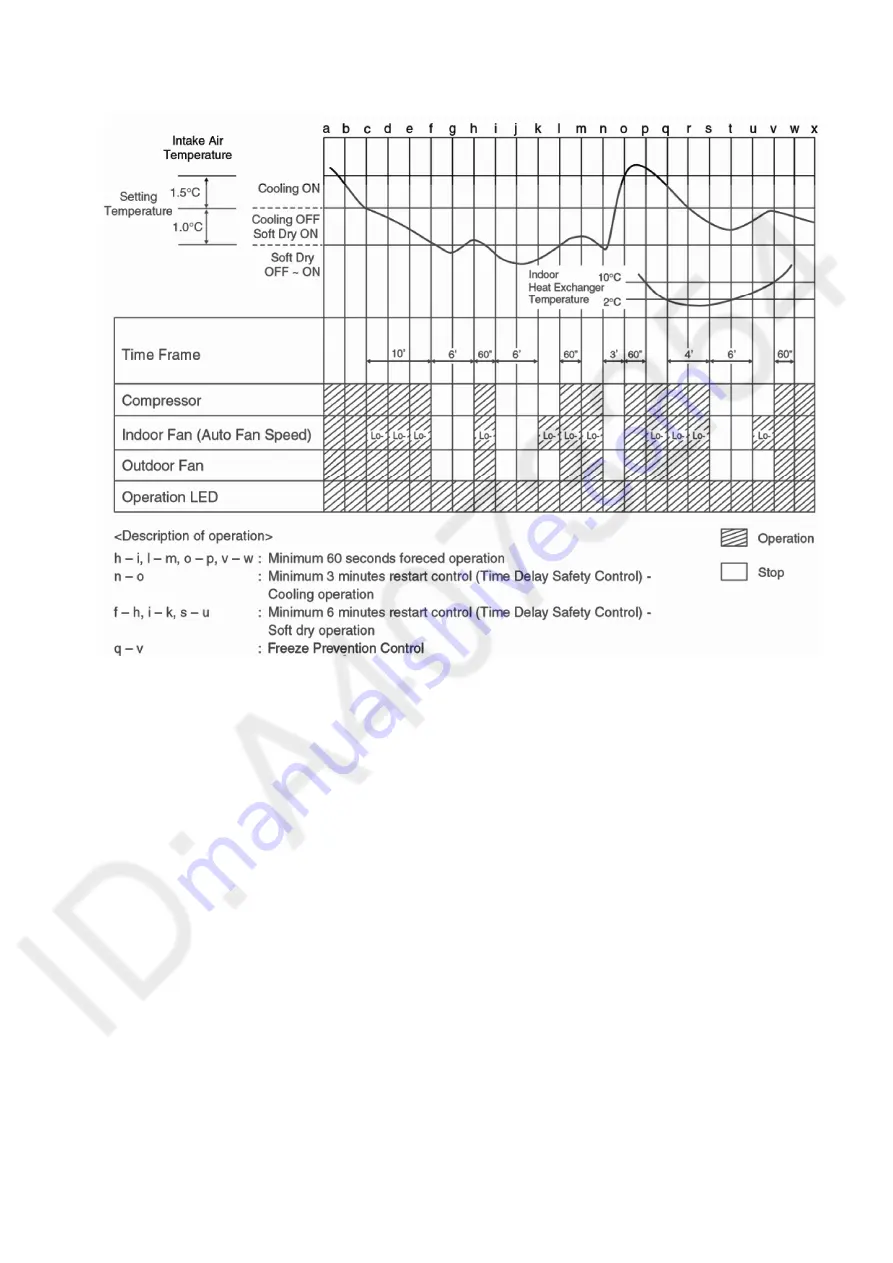

Page 105: ...105 18 Technical Data 18 1 Thermostat Characteristics...