49

2 Connect the center hose of the charging set to a vacuum pump.

3 Turn on the power switch of the vacuum pump and make sure that the needle in the gauge moves from

0 cmHg (0 MPa) to -76 cmHg (-0.1 MPa). Then evacuate the air approximately ten minutes.

4 Close the Low side valve of the charging set and turn off the vacuum pump. Make sure that the needle in the

gauge does not move after approximately five minutes.

Note : BE SURE TO TAKE THIS PROCEDURE IN ORDER TO AVOID REFRIGERANT GAS LEAKAGE.

5 Disconnect the charging hose from the vacuum pump and from the service port of the 3-way valve.

6 Tighten the service port caps of the 3-way valve at a torque of 18 N•m with a torque wrench.

7 Remove the valve caps of both of the 2-way valve and 3-way valve. Position both of the valves to “OPEN”

using a hexagonal wrench (4 mm).

8 Mount valve caps onto the 2-way valve and the 3-way valve.

o

Be sure to check for gas leakage.

If gauge needle does not move from 0 cmHg (0 MPa) to -76 cmHg (-0.1 MPa), in the step

e

above take

the following measure:

-

If the leak stops when the piping connections are tightened further, continue working from step

e

.

-

If the leak does not stop when the connections are retightened, repair location of leak.

-

Do not release refrigerant during piping work for installation and reinstallation.

-

Take care of the liquid refrigerant, it may cause frostbite.

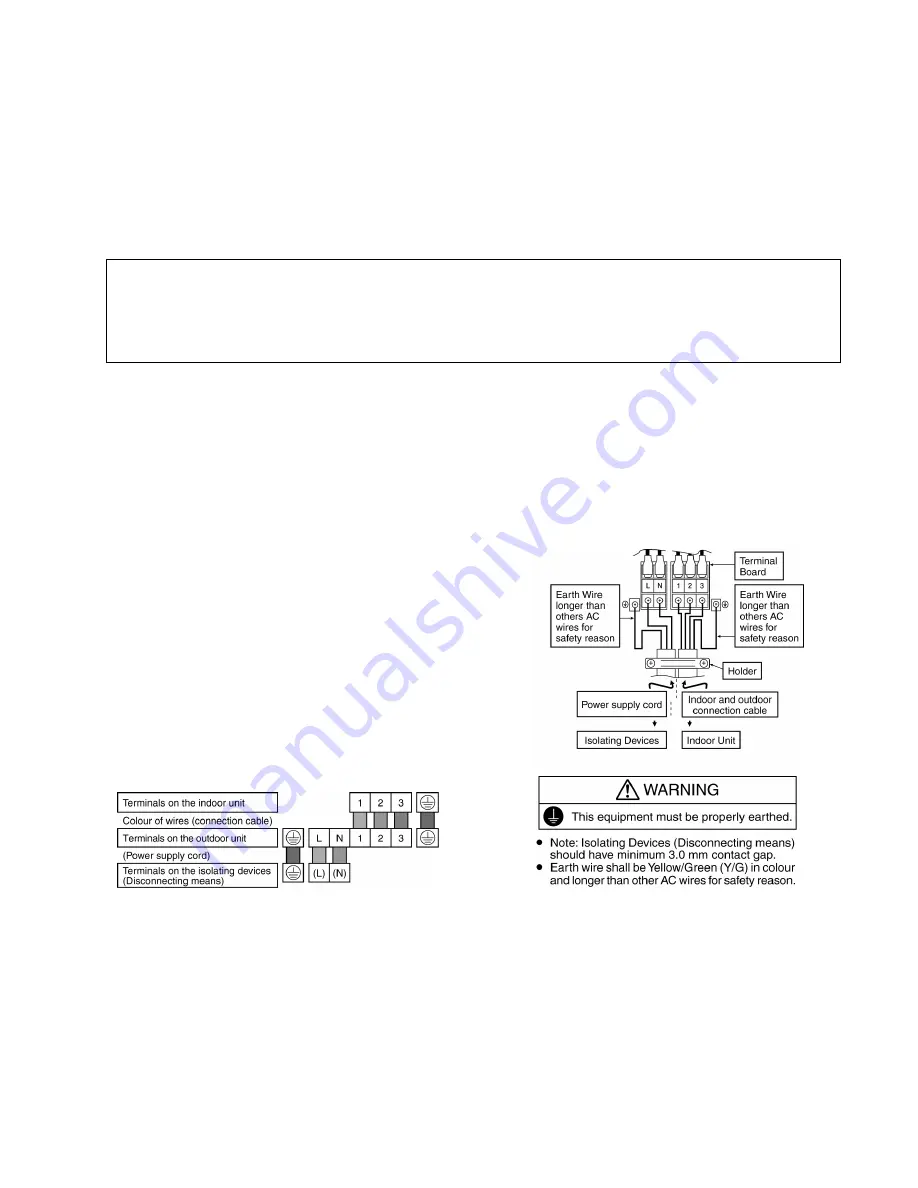

11.2.5 Connect the Cable to the Outdoor Unit

(FOR DETAIL REFER TO WIRING DIAGRAM AT

UNIT)

1 Remove the control board cover from the unit

by loosening the screw.

2 Cable connection to the power supply through

Isolating Devices (Disconnecting means).

o

Connect approved type polychloroprene

sheathed

power supply cord

3 x

1.5 mm

2

type designation 60245 IEC 57

or heavier cord to the terminal board, and

connect the others end of the cord to

Isolating Devices (Disconnecting means).

3

Connection cable

between indoor unit and

outdoor unit shall be approved

polychloroprene sheathed 4 x 1.5 mm

2

flexible

cord, type designation 60245 IEC 57 or

heavier cord. Allowable connection cable

length of each indoor unit shall be 30 m or

less.

4 Connect the power supply cord and

connection cable between indoor unit and

outdoor unit according to the diagram below.

5 Secure the power supply cord and connection

cable onto the control board with the holder.

6 Attach the control board cover back to the

original position with screw.

7 For wire stripping and connection

requirement, refer to instruction 10.1.6 of

indoor unit.

11.2.6 Pipe

Insulation

1 Please carry out insulation at pipe connection portion as mentioned in Indoor/Outdoor Unit Installation

Diagram. Please wrap the insulated piping end to prevent water from going inside the piping.

2 If drain hose or connecting piping is in the room (where dew may form), please increase the insulation by

using POLY-E FOAM with thickness 6 mm or above.

Summary of Contents for CS-E9PB4EA

Page 24: ...24 4 Location of Controls and Components 4 1 Indoor Unit 4 2 Outdoor Unit 4 3 Remote Control...

Page 25: ...25 5 Dimensions 5 1 Indoor Unit...

Page 26: ...26 5 2 Outdoor Unit 5 2 1 CU E9PB4EA 5 2 2 CU E12PB4EA...

Page 27: ...27 6 Refrigeration Cycle Diagram 6 1 CS E9PB4EA CU E9PB4EA...

Page 28: ...28 6 2 CS E12PB4EA CU E12PB4EA...

Page 29: ...29 7 Block Diagram 7 1 CS E9PB4EA CU E9PB4EA...

Page 30: ...30 7 2 CS E12PB4EA CU E12PB4EA...

Page 31: ...31 8 Wiring Connection Diagram 8 1 Indoor Unit...

Page 34: ...34 9 Electronic Circuit Diagram 9 1 Indoor Unit...

Page 35: ...35 9 2 Outdoor Unit 9 2 1 CU E9PB4EA...

Page 36: ...36 9 2 2 CU E12PB4EA...

Page 37: ...37 10 Printed Circuit Board 10 1 Indoor Unit 10 1 1 Main Printed Circuit Board...

Page 38: ...38 10 1 2 Display Printed Circuit Board...

Page 39: ...39 10 2 Outdoor Unit 10 2 1 CU E9PB4EA...

Page 40: ...40 10 2 2 CU E12PB4EA...

Page 65: ...65 14 3 2 CU E12PB4EA...

Page 106: ...106 18 Exploded View and Replacement Parts List 18 1 Indoor Unit...