This air conditioner uses the refrigerant R410A.

External diameter of service port R410A: 5/16"

Split System Air Conditioner

85264190577002

2011

INSTALLATION INSTRUCTIONS

NOTE

CV6233187839

Contents

Page

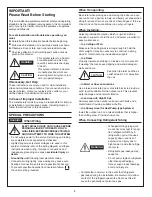

IMPORTANT!

Please Read Before Starting

..................................

2

1.

GENERAL

..........................................................

4

1-1. Tools Required for Installation (not supplied)

1-2. Accessories Supplied with Unit

1-3. Optional Copper Tubing Kit

1-4. Type of Copper Tube and Insulation Material

1-5. Additional Materials Required for Installation

2.

INSTALLATION SITE SELECTION

...................

5

2-1. Indoor Unit

2-2. Outdoor Unit

3.

HOW TO INSTALL THE INDOOR UNIT

.............

7

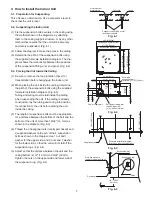

3-1. Preparation for Suspending

3-2. Suspending the Indoor Unit

3-3. Placing the Unit Inside the Ceiling

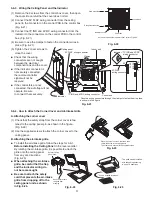

3-4. Installing the Drain Piping

3-5. Checking the Drainage

3-6. How to Install the Ceiling Panel

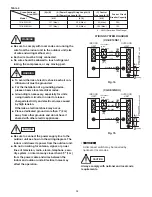

3-7. Wiring Instructions

3-8. Recommended Wire Length and Diameter

3-9. Wiring Instructions for Inter-unit Connections

4.

HOW TO INSTALL THE OUTDOOR UNIT

.......

15

4-1. Wiring Instructions for the Outdoor Unit

5.

REFRIGERANT TUBING

..................................

16

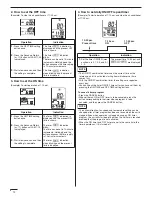

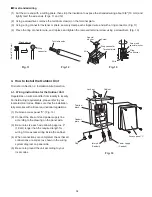

5-1. Use of the Flaring Method

5-2. Flaring Procedure with a Flare Tool

5-3. Caution before Connecting Tubes Tightly

5-4. Connecting Tubing between Indoor and

Outdoor Units

5-5. Insulation of Refrigerant Tubing

5-6. Taping the Tubes

5-7. Finishing the Installation

6.

AIR PURGING

...................................................

18

Air Purging with a Vacuum Pump (for Test Run)

Basic Functions of the Service Valves

Pump Down

Service Valve Connections

7.

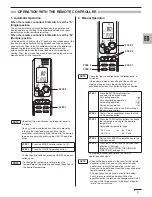

REMOTE CONTROLLER INSTALLATION

POSITION

.........................................................

22

7-1. Mounting on a Wall

8.

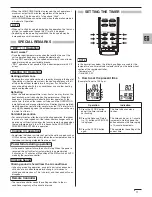

ADDRESS SWITCH

..........................................

23

8-1. Address Setting of the Remote Controller

Model Combinations

Combine indoor and outdoor units only as listed

below.

Model No.

Indoor Unit

Outdoor Unit

CS-KE12NB41

CU-KE12NK1

Power Source:

60 Hz, single-phase, 115 V

CS-KE18NB4UW

CU-KE18NKU

Power Source:

60 Hz, single-phase, 230/208 V

Ceiling Panel

CZ-18BT1U

Summary of Contents for CS-KE12NB41

Page 36: ...8FA2 5251 12200 2 Outdoor Unit CU KE12NK1 36 ...

Page 69: ......

Page 89: ......

Page 114: ...Operating Instructions CZ RD515U 852 6 4181 230 00 1 APPENDIX C A 3 ...

Page 125: ......

Page 126: ...A 4 INSTALLATION INSTRUCTIONS CZ RD515U 852 6 4190 592 00 0 APPENDIX D ...

Page 131: ......

Page 132: ...DC1111 0 ...