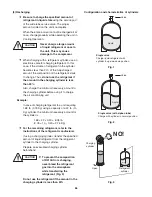

Insulation

tester

Probe

Clip

Ground wire

Terminal plate

Copper

tube or

metallic part

Clip

Insulation

tester

Probe

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Copper

tube or

metallic part

Clip

Insulation

tester

Probe

Clip

Insulation

tester

Probe

Metallic

part

From fan motor,

compressor and

other parts

10. CHECKING ELECTRICAL COMPONENTS

10-1. Measurement of Insulation

Resistance

The insulation is in good condition if the resistance

exceeds 1M ohm.

10-1-1. Power Supply Cord

Clamp the grounding wire of power cord with the lead

clip of the insulation resistance tester and measure the

resistance by placing a probe on either of the two

power wires. (Fig. 1)

Then also measure the resistance between the

grounding and other power terminals. (Fig. 1)

10-1-2. Indoor Unit

Clamp an aluminum plate fin or copper tube with the

lead clip of the insulation resistance tester and

measure the resistance by placing a probe on each

terminal screw on the terminal plate. (Fig. 2)

Note that the ground line terminal should be skipped

for the check.

10-1-3. Outdoor Unit

Clamp a metallic part of the unit with the lead clip of

the insulation resistance tester and measure the

resistance by placing a probe on each terminal screw

where power supply lines are connected on the

terminal plate. (Fig. 2)

10-1-4. Measurement of Insulation

Resistance for Electrical Parts

Disconnect the lead wires of the desired electric part

from terminal plate, capacitor, etc. Similarly disconnect

the connector. Then measure the insulation resistance.

(Figs. 3 and 4)

Refer to Electric Wiring Diagram.

If the probe cannot enter the poles because the hole is

too narrow then use a probe with a thinner pin.

NOTE

60

Summary of Contents for CS-KS12NB41

Page 37: ...Outdoor Unit CU KS12NK1A 8FA2 5251 12300 2 37 ...

Page 69: ......

Page 117: ......

Page 118: ...Operating Instructions CZ RD515U 852 6 4181 230 00 1 APPENDIX C A 3 ...

Page 129: ......

Page 130: ...A 4 INSTALLATION INSTRUCTIONS CZ RD515U 852 6 4190 592 00 0 APPENDIX D ...

Page 135: ......

Page 136: ...DC1111 0 ...