12

3-6-5. Checking After Installation

Check that there are no gaps between the unit and the ceiling panel, or between the ceiling panel and the ceiling sur-

face. Gaps may cause water leakage and condensation.

Check that the wiring is securely connected.

If it is not securely connected, the auto flap will not operate. In addition, water leakage and condensation may occur.

3-6-6. When Removing the Ceiling Panel for Servicing

When removing the ceiling panel for servicing, remove the air-intake grille and air filter, disconnect the flap and the indi-

cator wiring connectors inside the control box, and then remove the 4 mounting screws.

3-6-7. Adjusting the Auto Flap

The air-direction flap on the ceiling panel outlet can be adjusted as follows.

Adjust the flap to the desired angle using the remote controller. The flap also has an automatic air-sweeping mecha-

nism.

Never attempt to move the flap by hand.

Proper air flow depends on the location of the air conditioner, the layout of the room and furniture, etc. If cooling or

heating seems inadequate, try changing the direction of the air flow.

3-7. Wiring Instructions

General precautions on wiring

(1) Before wiring, confirm the rated voltage of the unit as shown on its nameplate, then carry out the wiring closely fol-

lowing the wiring diagram.

(2) Provide a power outlet to be used exclusively for each unit, with a power supply disconnect and circuit breaker for

overcurrent protection provided in the exclusive line.

(3) To prevent possible hazards due to insulation failure, the unit must be grounded.

(4) Each wiring connection must be done tightly and in accordance with the wiring system diagram. Wrong wiring may

cause the unit to misoperate or become damaged.

(5) Do not allow wiring to touch the refrigerant tubing, compressor, or any moving parts of the fan.

(6) Unauthorized changes in the internal wiring can be very dangerous. The manufacturer will accept no responsibility

for any damage or misoperation that occurs as a result of such unauthorized changes.

NOT

E

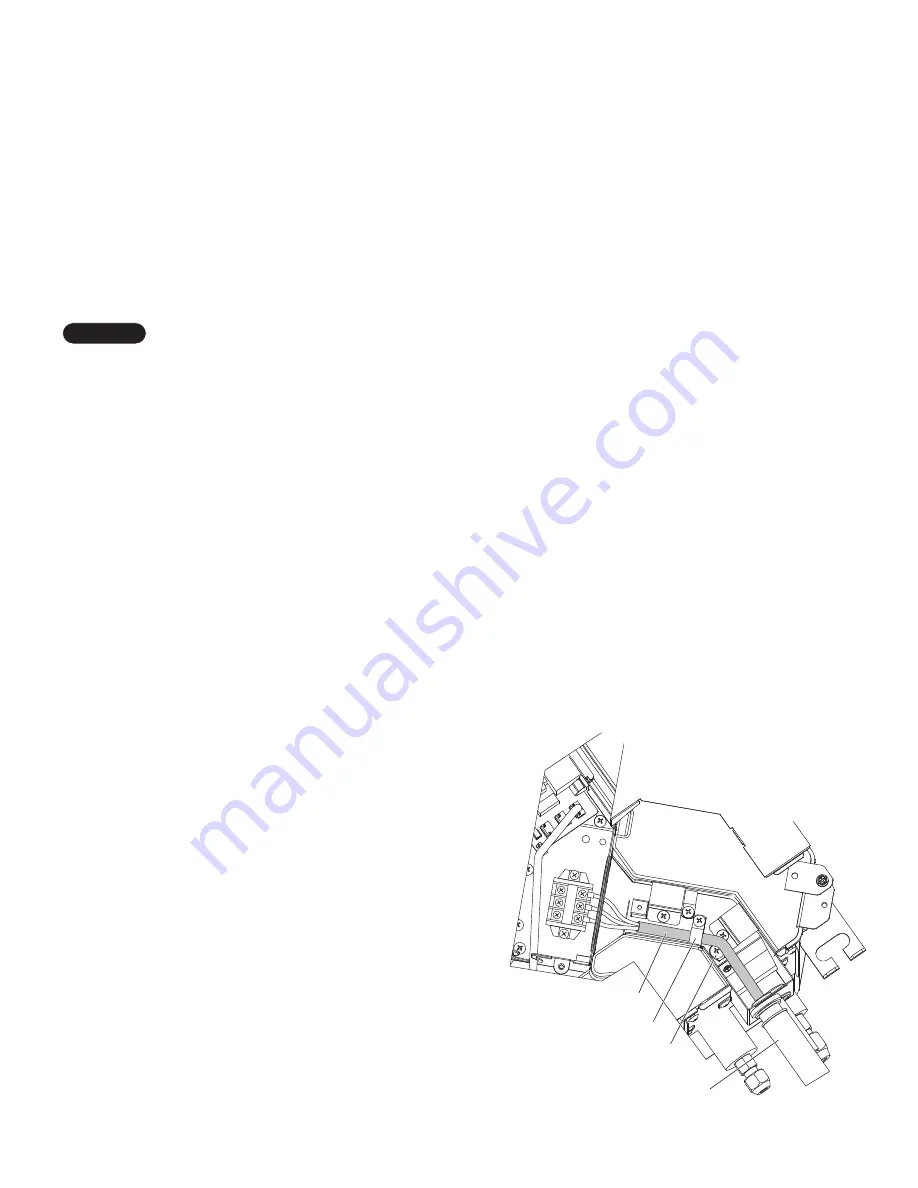

Fig. 8

1

3

2

Earth screw

Clamping strap

(Conduit)

Inter unit

Power wiring

(Locally purchased)

3-8. Wiring Instructions for Inter-unit Connections

(1) Remove the 1 screw from the terminal cover, then open the

cover. Be careful that the cover does not fall.

(2) Remove the 3 screws from the power box cover, then open

the cover. Be careful that the cover does not fall.

(3) Use the screw to securely fasten the ground wire from the

outdoor unit in place.

(4) Remove the transparent plastic cover from the 3P terminal

plate.

(5) While viewing the wiring diagram, connect the inter-unit and

power supply line to terminals 1, 2 and 3 on the 3P terminal

plate.

(6) Remount the transparent plastic cover onto the 3P terminal

plate.

(7) Be sure to use the clamping strap to fasten the wires in place.

(8) Tighten the screws to remount the terminal and the power

box cover.