30

12.2. Indoor Unit

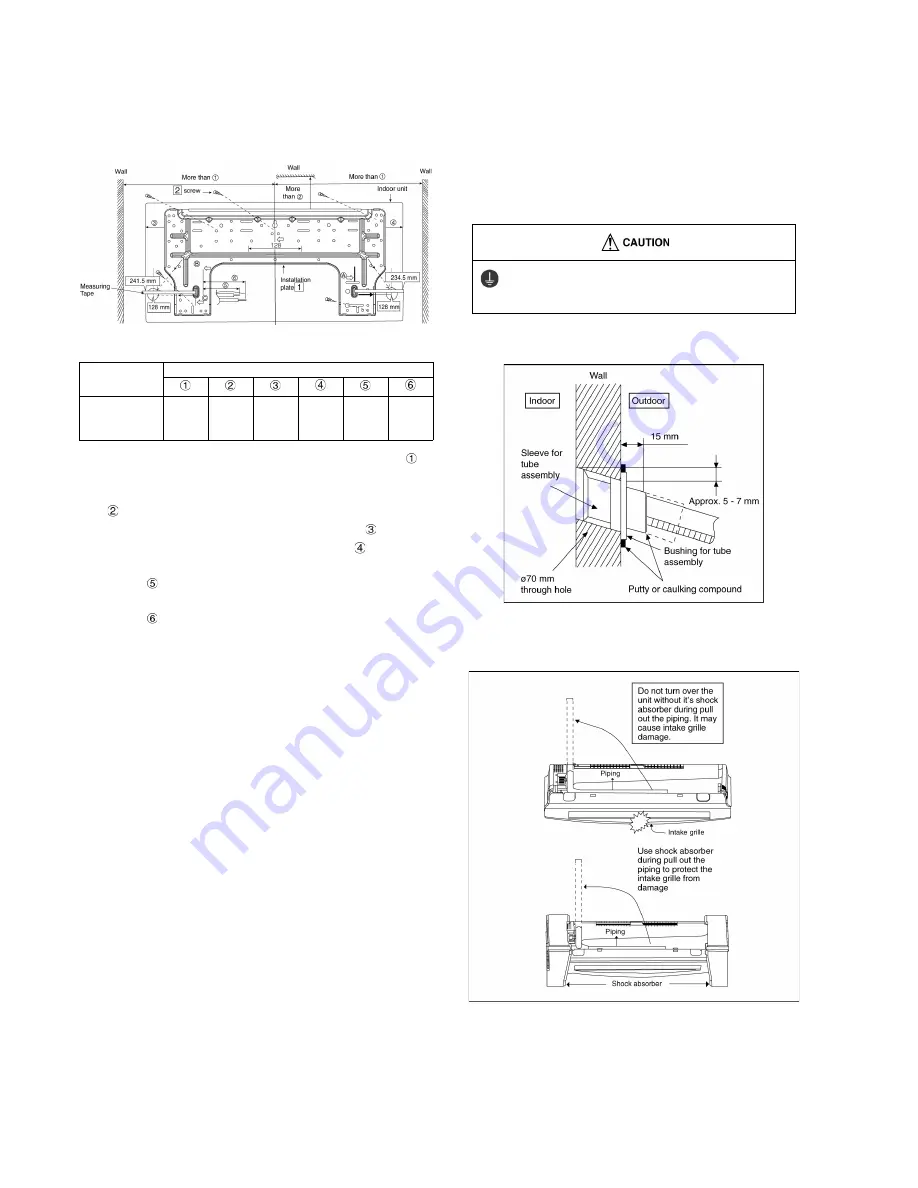

12.2.1. How to Fix Installation Plate

The mounting wall shall be strong and solid enough to prevent

it from the vibration.

The center of installation plate should be at more than at

right and left of the wall.

The distance from installation plate edge to ceiling should more

than .

From installation plate left edge to unit’s left side is .

From installation plate right edge to unit’s right is .

B

: For left side piping, piping connection for liquid should be

about from this line.

: For left side piping, piping connection for gas should be

about from this line.

1. Mount the installation plate on the wall with 5 screws or

more (at least 5 screws).

(If mounting the unit on the concrete wall, consider using

anchor bolts.)

• Always mount the installation plate horizontally by

aligning the marking-off line with the thread and using a

level gauge.

2. Drill the piping plate hole with ø70 mm hole-core drill.

• Line according to the left and right side of the installation

plate. The meeting point of the extended line is the

center of the hole. Another method is by putting

measuring tape at position as shown in the diagram

above. The hole center is obtained by measuring the

distance namely 128 mm for left and right hole

respectively.

• Drill the piping hole at either the right or the left and the

hole should be slightly slanting to the outdoor side.

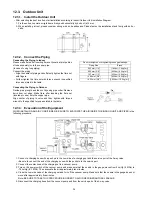

12.2.2. To Drill a Hole in the Wall and Install

a Sleeve of Piping

1. Insert the piping sleeve to the hole.

2. Fix the bushing to the sleeve.

3. Cut the sleeve until it extrudes about 15 mm from the

wall.

4. Finish by sealing the sleeve with putty or caulking

compound at the final stage.

12.2.3. Indoor Unit Installation

Model

Dimension

CS-MRE7***

CS-MRE9***

CS-MRE12***

485 mm 82 mm 165 mm 158 mm 43 mm 95 mm

When the wall is hollow, please be sure to use the sleeve

for tube assembly to prevent dangers caused by mice

biting the connection cable.

Summary of Contents for CS-MRE7MKE

Page 15: ...15 4 Location of Controls and Components 4 1 Indoor Unit 4 2 Outdoor Unit 4 3 Remote Control ...

Page 16: ...16 5 Dimensions 5 1 Indoor Unit ...

Page 17: ...17 5 2 Outdoor Unit ...

Page 18: ...18 6 Refrigeration Cycle Diagram ...

Page 19: ...19 7 Block Diagram ...

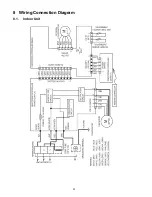

Page 20: ...20 8 Wiring Connection Diagram 8 1 Indoor Unit ...

Page 21: ...21 8 2 Outdoor Unit ...

Page 22: ...22 9 Electronic Circuit Diagram 9 1 Indoor Unit ...

Page 23: ...23 9 2 Outdoor Unit ...

Page 24: ...24 10 Printed Circuit Board 10 1 Indoor Unit 10 1 1 Main Printed Circuit Board ...

Page 25: ...25 10 1 2 Power Printed Circuit Board 10 1 3 Indicator Printed Circuit Board ...

Page 26: ...26 10 2 Outdoor Unit ...

Page 79: ...79 18 1 3 To remove power electronic controller 18 1 4 To remove discharge grille ...

Page 80: ...80 18 1 5 To remove control board 18 1 6 To remove cross flow fan and indoor fan motor ...

Page 81: ...81 ...

Page 85: ...85 ...

Page 86: ...86 19 1 1 2 CS MRE9MKE ...

Page 87: ...87 ...

Page 88: ...88 19 1 2 Two Indoor Unit Operation 19 1 2 1 CS MRE7MKE x2 ...

Page 89: ...89 ...

Page 90: ...90 19 1 2 2 CS MRE9MKE CS MRE7MKE ...

Page 91: ...91 ...

Page 93: ...93 ...

Page 94: ...94 19 2 1 2 CS MRE9MKE ...

Page 95: ...95 ...

Page 96: ...96 19 2 1 3 CS MRE12MKE ...

Page 97: ...97 ...

Page 98: ...98 19 2 2 Two Indoor Unit Operation 19 2 2 1 CS MRE7MKE x2 ...

Page 99: ...99 ...

Page 100: ...100 19 2 2 2 CS MRE9MKE x2 ...

Page 101: ...101 ...

Page 102: ...102 19 2 2 3 CS MRE12MKE x2 ...

Page 103: ...103 ...