34

12.3. Outdoor Unit

12.3.1. Install the Outdoor Unit

• After selecting the best location, start installation according to Indoor/Outdoor Unit Installation Diagram.

1. Fix the unit on concrete or rigid frame firmly and horizontally by bolt nut (ø10 mm).

2. When installing at roof, please consider strong wind and earthquake. Please fasten the installation stand firmly with bolt or

nails.

12.3.2. Connect the Piping

Connecting the Piping to Indoor

Please make flare after inserting flare nut (locate at joint portion

of tube assembly) onto the copper pipe.

(In case of using long piping)

Connect the piping

• Align the center of piping and sufficiently tighten the flare nut

with fingers.

• Further tighten the flare nut with torque wrench in specified

torque as stated in the table.

Connecting the Piping to Outdoor

Decide piping length and then cut by using pipe cutter. Remove

burrs from cut edge. Make flare after inserting the flare nut

(located at valve) onto the copper pipe.

Align center of piping to valve and then tighten with torque

wrench to the specified torque as stated in the table.

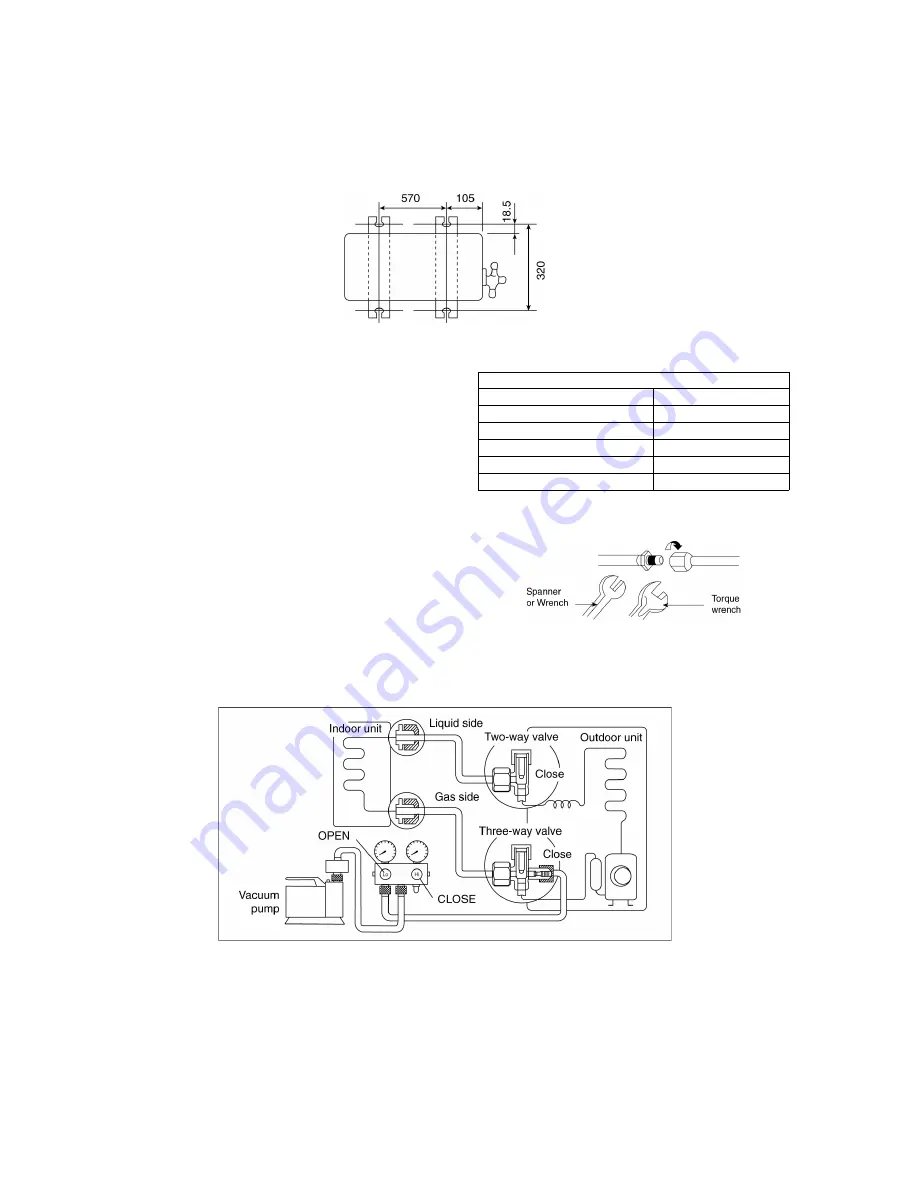

12.3.3. Evacuation of the Equipment

WHEN INSTALLING AN AIR CONDITIONER, BE SURE TO EVACUATE THE AIR INSIDE THE INDOOR UNIT AND PIPES in the

following procedure.

1. Connect a charging hose with a push pin to the Low side of a charging set and the service port of the 3-way valve.

• Be sure to connect the end of the charging hose with the push pin to the service port.

2. Connect the center hose of the charging set to a vacuum pump.

3. Turn on the power switch of the vacuum pump and make sure that the needle in the gauge moves from 0 cmHg (0 MPa) to

-76 cmHg (-0.1 MPa). Then evacuate the air approximately ten minutes.

4. Close the Low side valve of the charging set and turn off the vacuum pump. Make sure that the needle in the gauge does not

move after approximately five minutes.

Note: BE SURE TO TAKE THIS PROCEDURE IN ORDER TO AVOID REFRIGERANT GAS LEAKAGE.

5. Disconnect the charging hose from the vacuum pump and from the service port of the 3-way valve.

Do not overtighten, overtightening cause gas leakage.

Piping Size

Torque

6.35 mm (1/4”)

[18 N

m (1.8 kgf.m)]

9.52 mm (3/8”)

[42 N

m (4.3 kgf.m)]

12.7 mm (1/2”)

[55 N

m (5.6 kgf.m)]

15.88 mm (5/8”)

[65 N

m (6.6 kgf.m)]

19.05 mm (3/4”)

[100 N

m (10.2 kgf.m)]

Summary of Contents for CS-MRE7MKE

Page 15: ...15 4 Location of Controls and Components 4 1 Indoor Unit 4 2 Outdoor Unit 4 3 Remote Control ...

Page 16: ...16 5 Dimensions 5 1 Indoor Unit ...

Page 17: ...17 5 2 Outdoor Unit ...

Page 18: ...18 6 Refrigeration Cycle Diagram ...

Page 19: ...19 7 Block Diagram ...

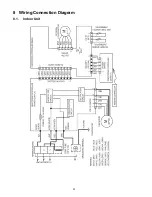

Page 20: ...20 8 Wiring Connection Diagram 8 1 Indoor Unit ...

Page 21: ...21 8 2 Outdoor Unit ...

Page 22: ...22 9 Electronic Circuit Diagram 9 1 Indoor Unit ...

Page 23: ...23 9 2 Outdoor Unit ...

Page 24: ...24 10 Printed Circuit Board 10 1 Indoor Unit 10 1 1 Main Printed Circuit Board ...

Page 25: ...25 10 1 2 Power Printed Circuit Board 10 1 3 Indicator Printed Circuit Board ...

Page 26: ...26 10 2 Outdoor Unit ...

Page 79: ...79 18 1 3 To remove power electronic controller 18 1 4 To remove discharge grille ...

Page 80: ...80 18 1 5 To remove control board 18 1 6 To remove cross flow fan and indoor fan motor ...

Page 81: ...81 ...

Page 85: ...85 ...

Page 86: ...86 19 1 1 2 CS MRE9MKE ...

Page 87: ...87 ...

Page 88: ...88 19 1 2 Two Indoor Unit Operation 19 1 2 1 CS MRE7MKE x2 ...

Page 89: ...89 ...

Page 90: ...90 19 1 2 2 CS MRE9MKE CS MRE7MKE ...

Page 91: ...91 ...

Page 93: ...93 ...

Page 94: ...94 19 2 1 2 CS MRE9MKE ...

Page 95: ...95 ...

Page 96: ...96 19 2 1 3 CS MRE12MKE ...

Page 97: ...97 ...

Page 98: ...98 19 2 2 Two Indoor Unit Operation 19 2 2 1 CS MRE7MKE x2 ...

Page 99: ...99 ...

Page 100: ...100 19 2 2 2 CS MRE9MKE x2 ...

Page 101: ...101 ...

Page 102: ...102 19 2 2 3 CS MRE12MKE x2 ...

Page 103: ...103 ...