25

11.4.2.3. Cutting And Flaring The Piping

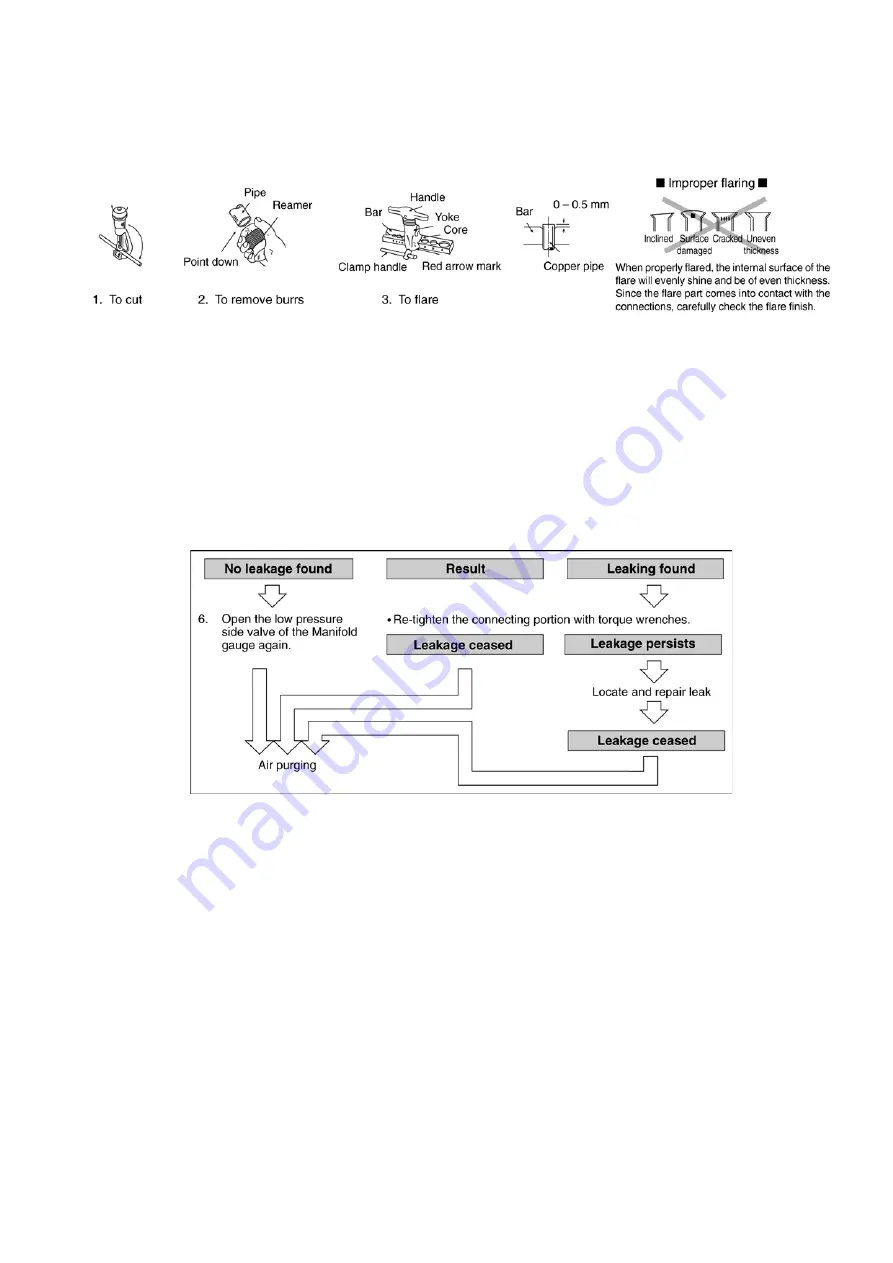

1. Please cut using pipe cutter and then remove the burrs.

2. Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused.

Turn the piping end down to avoid the metal powder entering the pipe.

3. Please make flare after inserting the flare nut onto the copper pipes.

11.4.3.

Air Purging Of The Pipings And Indoor Unit

1) Checking a gas leakage

1. Remove the service port cap from 3-way valves.

2. Connect the Manifold gauge set to the service port of liquid side 3-way valve.

3. Connect the Charging Cylinder to the Manifold gauge set and open the valve of the Cylinder.

4. Open the low pressure side valve of the Manifold gauge for approx.10 seconds and then close.

5. Check gas-leakage of the connecting portion of pipings with the gas-leak detector.

<For the left pipings>

1) Measure the pressure.

2) Keep it for 5-10 minutes.

• Ensure if the pressure indicated on the gauge is as same as that of measured at first time.

Summary of Contents for CS-PC36HKV

Page 9: ...9 5 Dimensions 5 1 Indoor Unit Remote Control 5 1 1 CS PC36HKV...

Page 10: ...10 5 2 Outdoor Unit 5 2 1 CU PC36HKV...

Page 11: ...11 6 Refrigeration Cycle Diagram...

Page 12: ...12 7 Block Diagram...

Page 13: ...13 8 Wiring Connection Diagram...

Page 14: ...14 9 Electronic Circuit Diagram 9 1 CS PC36HKV...

Page 15: ...15 9 2 CU PC36HKV...

Page 16: ...16 10 Printed Circuit Board 10 1 Indoor Unit...

Page 17: ...17 10 2 Outdoor Unit...

Page 18: ...18 10 3 Indicator...

Page 22: ...22 This can be used for left rear piping and left bottom piping also...

Page 45: ...45 17 Technical Data 17 1 Thermostat Characteristics Cooling Soft Dry...

Page 46: ...46 17 2 Operation Characteristics 17 2 1 CS PC36HKV CU PC36HKV...

Page 47: ...47...

Page 50: ...50 18 2 Outdoor Unit 18 2 1 CU PC36HKV...

Page 51: ...51...