10.1. Evacuation of Installation

When installing an air conditioner, be sure to evacuate the air inside the indoor unit and pipes in the following procedure.

Required tools:

Hexagonal wrench, adjustable wrench, torque wrench,

wrench to hold the joints, gas leak detector, charging set

and vacuum pump.

The air in the indoor unit and in the piping must be purged.

If air remains in the refrigeration piping, it will affect the

compressor , reduce cooling capacity, and could lead to a

malfunction.

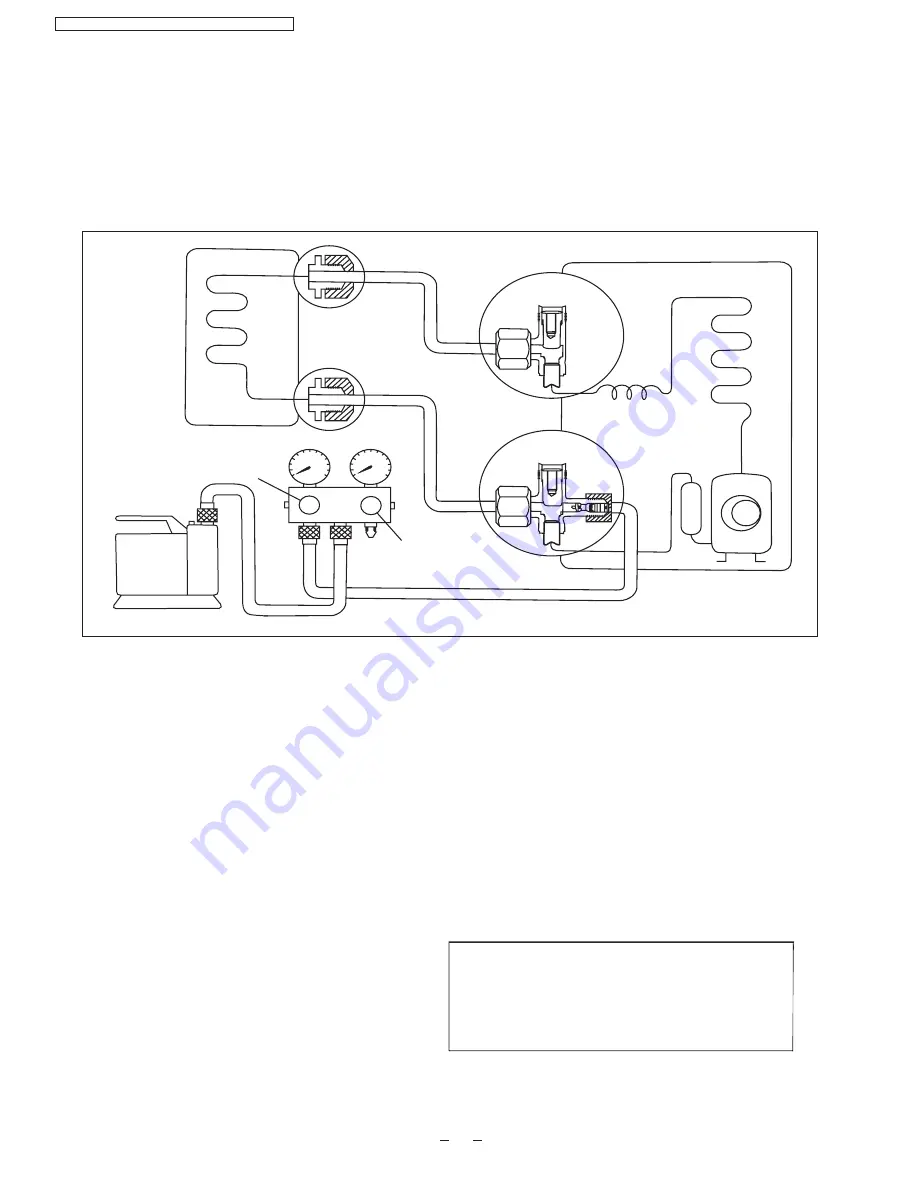

(Indoor unit)

(Liquid side)

(Outdoor unit)

2-way

valve

(Gas side)

Open

3-way

valve

Open

Low

High

Open

Closed

Service port cap

Be sure, using a torque wrench to tighten the service port cap(after using the service port),so that it prevents the gas leakage

from the refrigeration cycle.

Procedure:

1 Connect a charging hose with a push pin to the

Low

side of a charging set and the service port of the 3-way

valve.

2.Connect the centre hose of the charging set to a

vacuum pump.

3.Turn on the power switch of the vacuum pump and

make sure that the needle in the gauge moves from 0

cmHg (0 Mpa) to -76 cmHg (-0.1 Mpa). Then evacuate

the air for approximately 10 minutes.

4.Close the valve of the Low side of the charging set

and turn off the vacuum pump. Make sure that the

needle in the gauge does not move after approximately

5 minutes.

BE SURE TO TAKE THIS PROCEDURE IN ORDER TO

AVOID GAS REFRIGERANT LEAKAGE.

5.Disconnect the charging hose from the vacuum pump

and from the service port of the 3-way valve.

.

Be sure to connect the end of the charging hose with the

push pin to the service port.

6.Tighten the service port caps of both the 3-way valve

and the 2-way valve at a torque of18 N.m with a torque

wrench.

7.Remove the valve caps of both the 3-way and the 2-way

valves.

Position both of the valves to

using a hexagonal

wrench (4 mm).

8.Mount valve caps onto both of the 3-way valve and the

2-way valve.

“open”

36

Vacuum Pump

Caution

If gauge needle does not move from 0 cmHg(0 Mpa) to -76cmHg

(-0.1MPa) in step (3) above, take the following measures:

If the leaks stop when the piping connections are tightened

further, continue working from step (3).

If the leaks do not stop when the connections are retightened,

repair the location of the leak.

Be sure to check for gas leakage.

CS-PC9DKV / CU-

/ CS-

/ CU-

PC9DKV

PC12DKV

PC12DKV