49

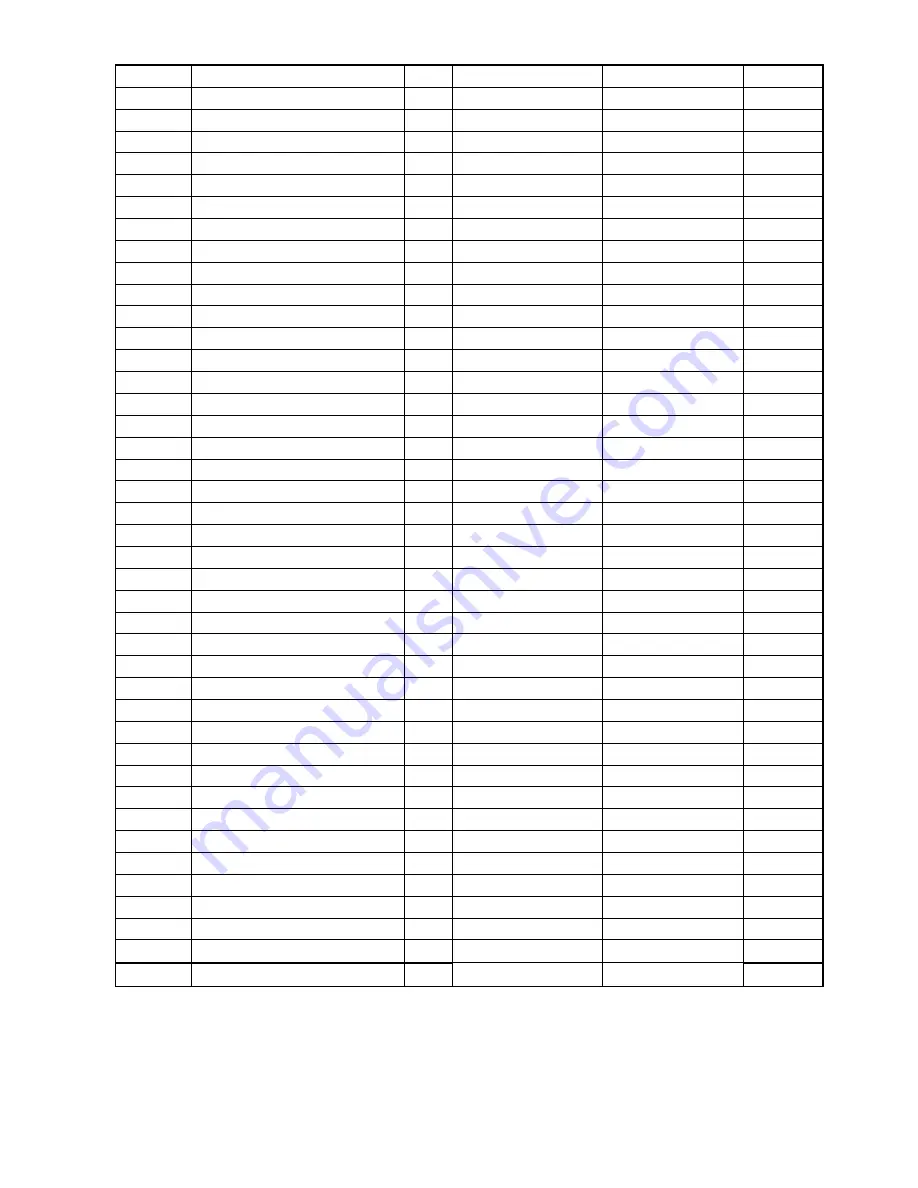

NO PART

NAME&DESCRIPTION

Q'TY

CU-RE9JKE

CU-RE12JKE

RE

1 CHASSIS

ASS'Y

1

CWD50K2193A

CWD50K2193A

ʳ

2

FAN MOTOR BRACKET

1

CWD541123

CWD541123

ʳ

3

SCREW-FAN MOTOR BRACKET

2

CWH551148A

CWH551148A

ʳ

4

FAN MOTOR

1

CWA951654

CWA951656

ʳ

5

SCREW-FAN MOTOR MOUNT

3

CWH55406J

CWH55406J

ʳ

6 PROPELLER

FAN

ASS'Y

1

CWH03K1034

CWH03K1034

ʳ

7

NUT-PROPELLER FAN

1

CWH561036J

CWH561036J

ʳ

8 COMPRESSOR

1

CWB092256

CWB092256

ʳ

9 ANTI-VIBRATION

BUSHING

3

CWH50077

CWH50077

ʳ

10 NUT-COMPRESSOR

MOUNT

3

CWH56000J

CWH56000J

ʳ

11 CONDENSER

1

CWB32C2386

CWB32C2182

ʳ

12 TUBE

ASSY

1

CWT023064

CWT023064

ʳ

13

HOLDER COUPLING ASS'Y

1

CWH351071

CWH351071

ʳ

14 4-WAY

VALVE

1

CWB001037J

CWB001037J

ʳ

15 2-WAY

VALVE

1

CWB021497

B021497

ʳ

16 3-WAY

VALVE

1

CWB011603

CWB011603

ʳ

17 STRAINER

1

CWB111026

CWB111026

ʳ

18 TERMINAL

COVER

1

CWH171048

CWH171048

ʳ

19

NUT FOR TERMIANL COVER

1

7080300J

7080300J

ʳ

20

SOUND PROOF BOARD

1

CWH151187

CWH151187

ʳ

21

SOUND PROOF MATERIAL

1

CWG302433

CWG302433

ʳ

22

TUBE (NOISE SUPPRESSOR)

1

CWB121016

CWB121016

ʳ

23 REACTOR

1

G0C193J00007

G0C193J00007

ʳ

24 CONTROL

BOX

COMPLETE

1

CWH14C6793

CWH14C6794

ʳ

26

TERMINAL BOARD ASS'Y

1

CWA28K1185

CWA28K1185

ʳ

27

CONTROL BOARD CASING

1

CWH102298

CWH102298

ʳ

28 COVER-CONTROL

BOX

1

CWH131300

CWH131300

ʳ

29 ELECTRONIC

CONTROLLER

1

CWA73C3609

CWA73C3610

ʳ

30

SENSOR COMPLETE

ΰ

COMP.)

1 CWA50C2209J

CWA50C2209J

ʳ

31 SENSOR

COMPLETE(PIPING)

1

CWA50C2521

CWA50C2521

ʳ

32 TUBE

ASS'Y(CAPILLARY)

1

CWT01C4907

CWT01C4908

ʳ

33 CAPILLARY

1

CWB15471

CWB15323

ʳ

CAPILLARY

----

CWB15395

34 V-COIL

COMPLETE

1

CWA43C2261

CWA43C2261

ʳ

35

CONTROL BOARD COVER(IN)

1

CWH131354 CWH131354

ʳ

37 TOP

PLATE

1

CWE031084A

CWE031084A

ʳ

38

CABINET FRONT PLATE

1

CWE06C1231

CWE06C1231

ʳ

39

CABINET SIDE PLATE (R)

1

CWE041301A

CWE041301A

ʳ

40

CABINET SIDE PLATE (L)

1

CWE041247A

CWE041247A

ʳ

41

CONTROL BOARD COVER(OUT)

1

CWH131277

CWH131277

42 HANDLE

1

CWE161001

CWE161001

ʳ

(Note)

x

All parts are supplied from PHAAG, China.

Summary of Contents for CS-RE9JKE

Page 14: ...14 5 2 Outdoor Unit Unit mm...

Page 15: ...15 6 Refrigeration Cycle Diagram CS CU RE9JKE CS CU RE12JKE CS CU RE15JKE COOLING HEATING...

Page 16: ...16 7 Block Diagram CS CU RE15JKE CS CU RE9 12JKE...

Page 17: ...17 8 Wiring Diagram 6 8 5 6 8 5...

Page 18: ...18 6 8 5...

Page 19: ...19 9 Printed Circuit Board 9 1 Indoor Unit 9 1 1 Main Printed Circuit Board TOP VIEW...

Page 20: ...20 BOTTOM VIEW...

Page 21: ...21 9 1 2 Indicator receiver TOP VIEW BOTTOM VIEW...

Page 22: ...22 9 2 Outdoor Unit 9 2 1 CU RE9JKE CU RE12JKE TOP VIEW BOTTOM VIEW...

Page 25: ...25 10 2 3 Indoor Unit Installation...

Page 42: ...42 14 2 3 Error Codes Table...

Page 46: ...46 16 Exploded View and Replacement Pars List 16 1 Indoor Unit CS RE9JKE CS RE12JKE CS RE15JKE...

Page 48: ...48 16 2 Outdoor Unit CU RE9JKE CU RE12JKE...

Page 50: ...50 CU RE15JKE...