Summary of Contents for CS-TE15HKE

Page 8: ...8 5 Dimensions 5 1 Indoor Unit...

Page 9: ...9 5 2 Outdoor Unit...

Page 10: ...10 6 Refrigeration Cycle Diagram...

Page 11: ...11 7 Block Diagram...

Page 12: ...12 8 Wiring Connection Diagram 8 1 Indoor Unit...

Page 13: ...13 8 2 Outdoor Unit...

Page 14: ...14 9 Electronic Circuit Diagram 9 1 Indoor Unit...

Page 15: ...15 9 2 Outdoor Unit...

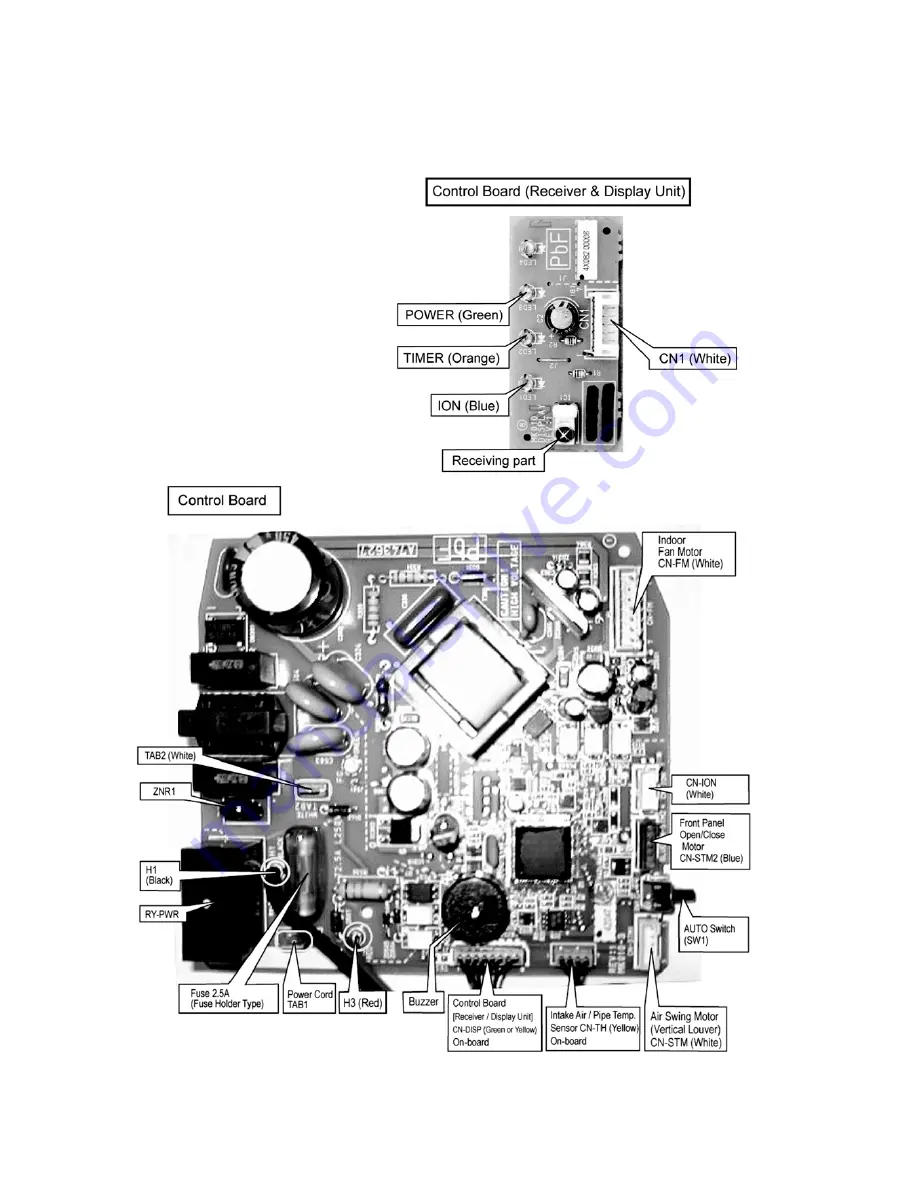

Page 16: ...16 10 Printed Circuit Board 10 1 Indoor Unit 10 1 1 Printed Circuit Board...

Page 17: ...17 10 2 Outdoor Unit 10 2 1 Main Printed Circuit Board...

Page 20: ...20 3 For the embedded piping This can be used for left rear piping and left bottom piping also...

Page 43: ...43 16 1 2 Removal of Electronic Controller...

Page 44: ...44 16 1 3 Removal of Control Board...

Page 45: ...45 16 1 4 Removal of Fan Motor and Cross Flow Fan...

Page 46: ...46...

Page 48: ...48 17 Technical Data 17 1 Operation Characteristics...

Page 49: ...49...

Page 50: ...50...

Page 51: ...51...