11.4.5. Recharging Refrigerant During Servicing

When recharging is necessary, insert the specified amount of new refrigerant in accordance with the following procedure.

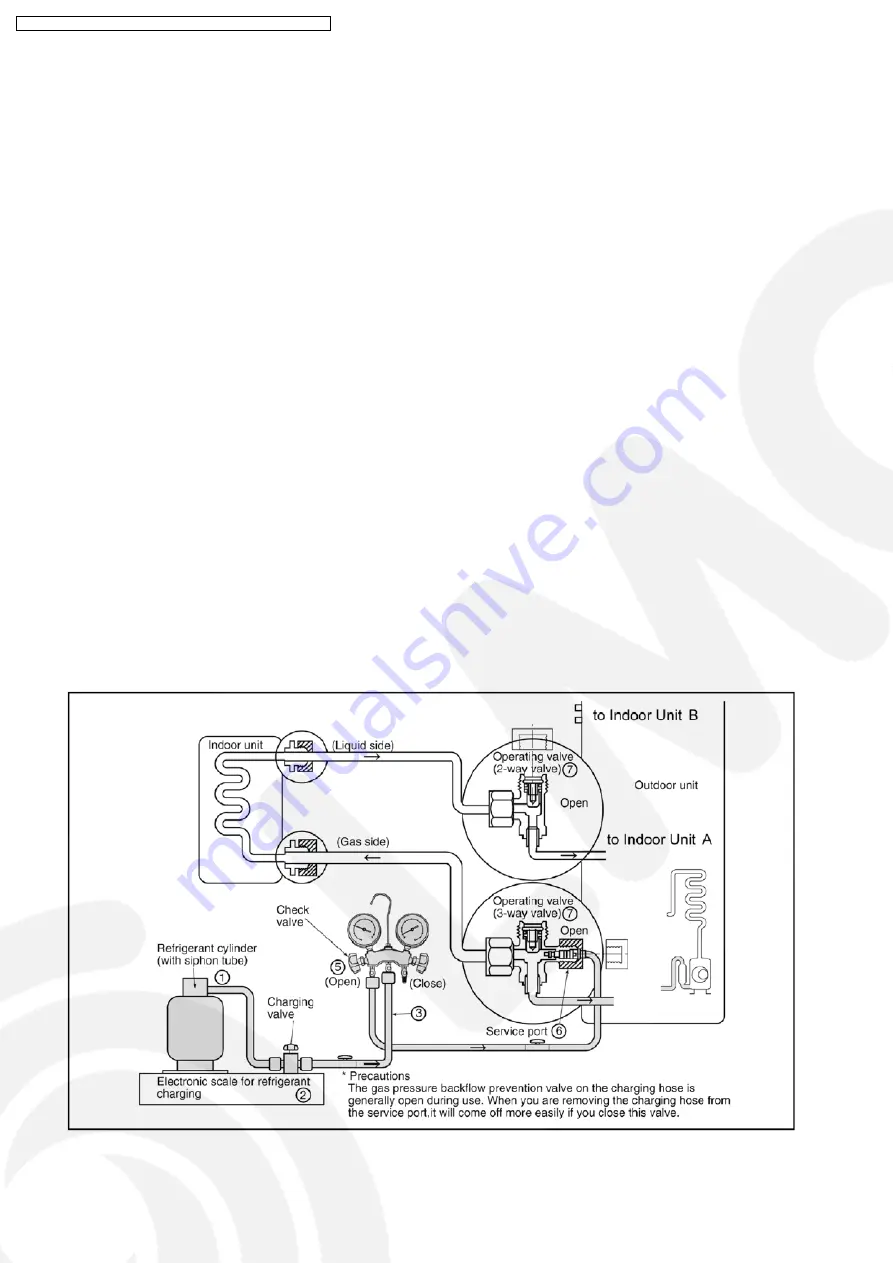

1. Connect the charging hose to the service port of the outdoor unit.

2. Connect the charging hose to the vacuum pump adaptor. At this time, fully open the 2-way valve and 3-way valve.

3. Fully open the handle Lo of the manifold gauge, turn on the power of the vacuum pump and continue the vacuum process for

at least one hour.

4. Confirm that the low pressure gauge shows a reading of -0.1 Mpa (-76 cmHg), then fully close the handle Lo, and turn off the

vacuum pump. Wait for 1-2 minutes, then check to make sure that the needle of the Low pressure gauge has not returned. See

Fig. 13 for the remaining steps of this procedure.

5. Set the refrigerant cylinder onto the electronic scale, then connect the hose the cylinder and to the connection port for the

electronic scale. (1)(2)

Precaution:

Be sure to set up the cylinder for liquid charging. If you use a cylinder equipped with a siphon tube, you can charge the liquid

without having to turn the cylinder around

6. Remove the charging hose of the manifold gauge from the vacuum pump adaptor, and connect it to the connection port of the

electronic scale. (2)(3)

7. Open the valve of the refrigerant cylinder, then open the charging valve slightly and close it. Next, press the check valve of the

manifold gauge and purge the air. (2)(4) (Watch the liquid refrigerant closely at this point.)

8. After adjusting the electronic scale to zero, open the charging valve, then open the valve Lo of the manifold gauge and charge

with the liquid refrigerant. (2)(5) (Be sure to read the operating instructions for the electronic scale.)

9. If you cannot charge the stipulated amount, operate the unit in the cooling mode while charging a little of the liquid at a time

(about 150 g/time as a guideline). If the charging amount is insufficient from one operation, wait about one minute, then use the

same procedure to do the liquid charging again.

Precaution:

Never use the gas side to allow a larger amount of liquid refrigerant to be charged while operating the unit.

10. Close the charging valve, and after charging the liquid refrigerant inside the charging hose, fully close the valve Lo of the

manifold gauge, and stop the operation of the unit. (2)(5)

11. Quickly remove the charging hose from the service port. (6) If you stop midway through, the refrigerant that is in the cycle will

be discharged.

12. After putting on the caps for the service port and operating valve, inspect around the caps for a gas leak. (6)(7)

Fig. 13 Re-charging refrigerant

54

CS-V7DKE CU-V7DKE / CS-V9DKE CU-V9DKE / CS-V12DKE CU-V12DKE

Summary of Contents for CS-V7DKE

Page 15: ...5 Refrigeration Cycle Diagram 15 CS V7DKE CU V7DKE CS V9DKE CU V9DKE CS V12DKE CU V12DKE...

Page 16: ...6 Block Diagram 16 CS V7DKE CU V7DKE CS V9DKE CU V9DKE CS V12DKE CU V12DKE...

Page 17: ...7 Wiring Diagram 17 CS V7DKE CU V7DKE CS V9DKE CU V9DKE CS V12DKE CU V12DKE...

Page 64: ...14 3 3 CS V12DKE CU V12DKE 64 CS V7DKE CU V7DKE CS V9DKE CU V9DKE CS V12DKE CU V12DKE...

Page 75: ...75 CS V7DKE CU V7DKE CS V9DKE CU V9DKE CS V12DKE CU V12DKE...

Page 77: ...19 2 Remote Control 77 CS V7DKE CU V7DKE CS V9DKE CU V9DKE CS V12DKE CU V12DKE...

Page 79: ...TOP VIEW 79 CS V7DKE CU V7DKE CS V9DKE CU V9DKE CS V12DKE CU V12DKE...