59

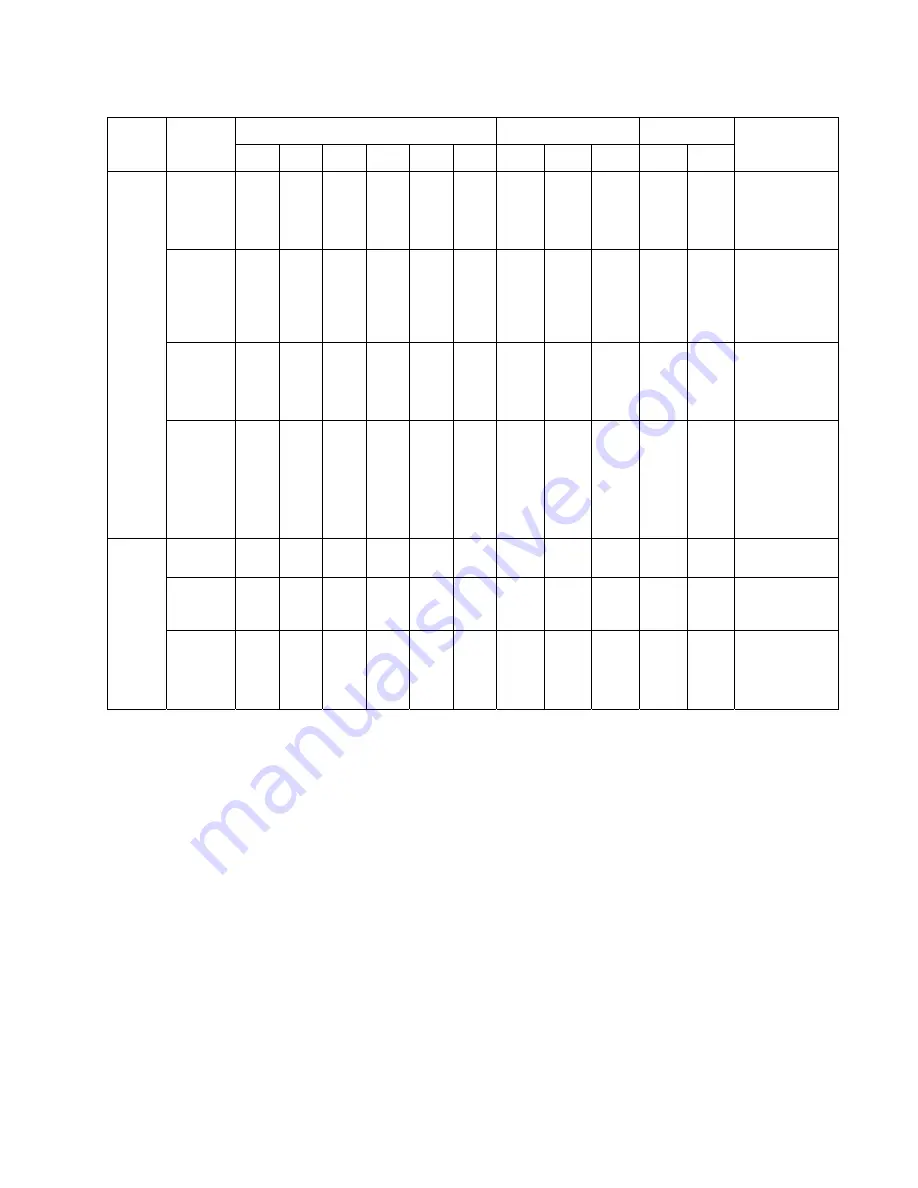

12.7.7 Selection of brazing material

Use BA

g

brazing material (silver solder) to increase the welding performance.

Category

JIS

Standard

Number

Composition of ingredients (%)

Temperature (°C)

Tensile strength

(Reference)

Characteristics

and

applications

A

g

Cu

Zu

Cd

Ni

P

Solidus Liquidus

Brazing

temp

K

g

f•cm

2

Base

material

BA

g

BA

g

•

1A

49.0

~

51.0

14.5

~

16.5

14.5

~

18.5

17.0

~

19.0

—

—

approx.

625

approx.

635

635

~

760

45.5

S20C

Liquidity is good at

low temperature,

it is preferable to

a small junction of

the gap in the

universal form.

BA

g

•

1

44.0

~

56.0

14.0

~

16.0

14.0

~

18.0

23.0

~

25.0

—

—

approx.

605

approx.

620

620

~

760

45.5

S20C

It has similar

performance to the

BA

g

•

1A, and

suitable for every

base material

except the light

weight metal.

BA

g

•

2

34.0

~

36.0

25.0

~

27.0

19.0

~

23.0

17.0

~

19.0

—

—

approx.

605

approx.

700

700

~

845

45.5

S20C

It is a brazing

filler metal in

universal form,

suitable for a

slightly larger gap

junction.

BA

g

•

3

48.0

~

51.0

14.5

~

16.5

13.5

~

17.5

15.0

~

17.0

2.5

~

3.5

—

approx.

630

approx.

690

690

~

815

35

~

70

SS

~

SUS

It has good

corrosion

resistance in

stainless

steel-based

brazing, suitable for

brazing tungsten

carbide, aluminum

bronze and copper.

BCuP

BCuP-2

—

remain

—

—

—

6.8

~

7.5

approx.

710

approx.

785

690

~

815

21

~

24.5

Cu

Good liquidity,

suitable for brazing

copper tube.

BCuP-3

4.8

~

5.2

remain

—

—

—

5.8

~

6.7

approx.

645

approx.

815

720

~

815

21

~

24.5

Cu

Suitable for brazing

when the joint

spacing is not

constant

BCuP-5

14.5

~

15.5

remain

—

—

—

4.8

~

5.3

approx.

645

approx.

800

705

~

815

21

~

24.5

Cu

When brazing of

copper and copper,

it is used without a

flux, but not

possible for brazing

basic materials

Caution

BCuP (phosphorus copper wax) is easy to react with sulfur, and makes a brittle compound water soluble, and causes

gas leakage. In hot spring areas, use other brazing materials or paint the surface for protection.

12.7.8 Need of flux

Use flux to protect the base materials.

1. Remove impurity and oxide film on the metal base, and improve the flow of the brazing material.

2. Prevent oxidation of the metal surface in brazing.

3. Reduce the surface tension of the brazing material.

12.7.9 Need of nitrogen gas

In order to prevent oxidation in the pipe, perform the brazing operation in nitrogen gas flow.

Flow rate 0.05 m

3

/ h, or pressure reducing valve at 0.02 MPa (0.2k

g

f / cm

2

) below.