- 2 -

Important Safety Notice

Special components are used in this television set which are important for safety. These parts are identified on the

schematic diagram by the symbol

and printed in BOLD TYPE on the replacement part list. It is essential that

these critical parts are replaced with the manufacturer’s specified replacement part to prevent X-ray radiation,

shock, fire or other hazards. Do not modify the original design without the manufacturer’s permission.

Safety Precautions

General Guidelines

An Isolation Transformer should always be used during

the servicing of a receiver whose chassis is not

isolated from AC power line. Use a transformer of

adequate power rating as this protects the technician

from accidents resulting in personal injury from

electrical shocks. It will also protect the Receiver from

being damaged by accidental shorting that may occur

during servicing.

When servicing, observe the original lead dress,

especially in the high voltage circuit. Replace all

damaged parts (also parts that show signs of

overheating.)

Always Replace Protective Devices, such as fishpaper,

isolation resistors and capacitors, and shields after

servicing the Receiver. Use only manufacturer’s

recommended rating for fuses, circuits breakers, etc.

High potentials are present when this Receiver is

operating. Operation of the Receiver without the rear

cover introduces danger for electrical shock. Servicing

should not be performed by anyone who is not

thoroughly familiar with the necessary precautions

when servicing high-voltage equipment.

Extreme care should be practiced when Handling the

Picture Tube. Rough handling may cause it to implode

due to atmospheric pressure. (14.7 lbs per sq. in.). Do

not nick or scratch the glass or subject it to any undue

pressure. When handling, use safety goggles and

heavy gloves for protection. Discharge the picture tube

by shorting the anode to chassis ground (not to the

cabinet or to other mounting hardware). When

discharging connect cold ground (i.e. dag ground lead)

to the anode with a well insulated wire or use a

grounding probe.

Avoid prolonged exposure at close range to unshielded

areas of the picture tube to prevent exposure to

X-ray radiation.

The Test Picture Tube used for servicing the chassis at

the bench should incorporate safety glass and

magnetic shielding. The safety glass provide shielding

for the tube viewing area against X-ray radiation as

well as implosion. The magnetic shield limits the X-ray

radiation around the bell of the picture tube in addition

to the restricting magnetic effects. When using a

picture tube test jig for service, ensure that the jig is

capable of handling 35kV without causing

X-ray radiation.

Before returning a serviced receiver to the owner, the

service technician must thoroughly test the unit to

ensure that is completely safe to operate. Do not use a

line isolation transformer when testing.

Leakage Current Cold Check

Unplug the AC cord and connect a jumper between the

two plug prongs.

Measure the resistance between the jumpered AC plug

and expose metallic parts such as screwheads,

antenna terminals, control shafts, etc.

If the exposed metallic part has a return path to the

chassis, the reading should be between 240k

Ω

and

5.2M

Ω.

If the exposed metallic part does not have a

return path to the chassis, the reading should be

infinite.

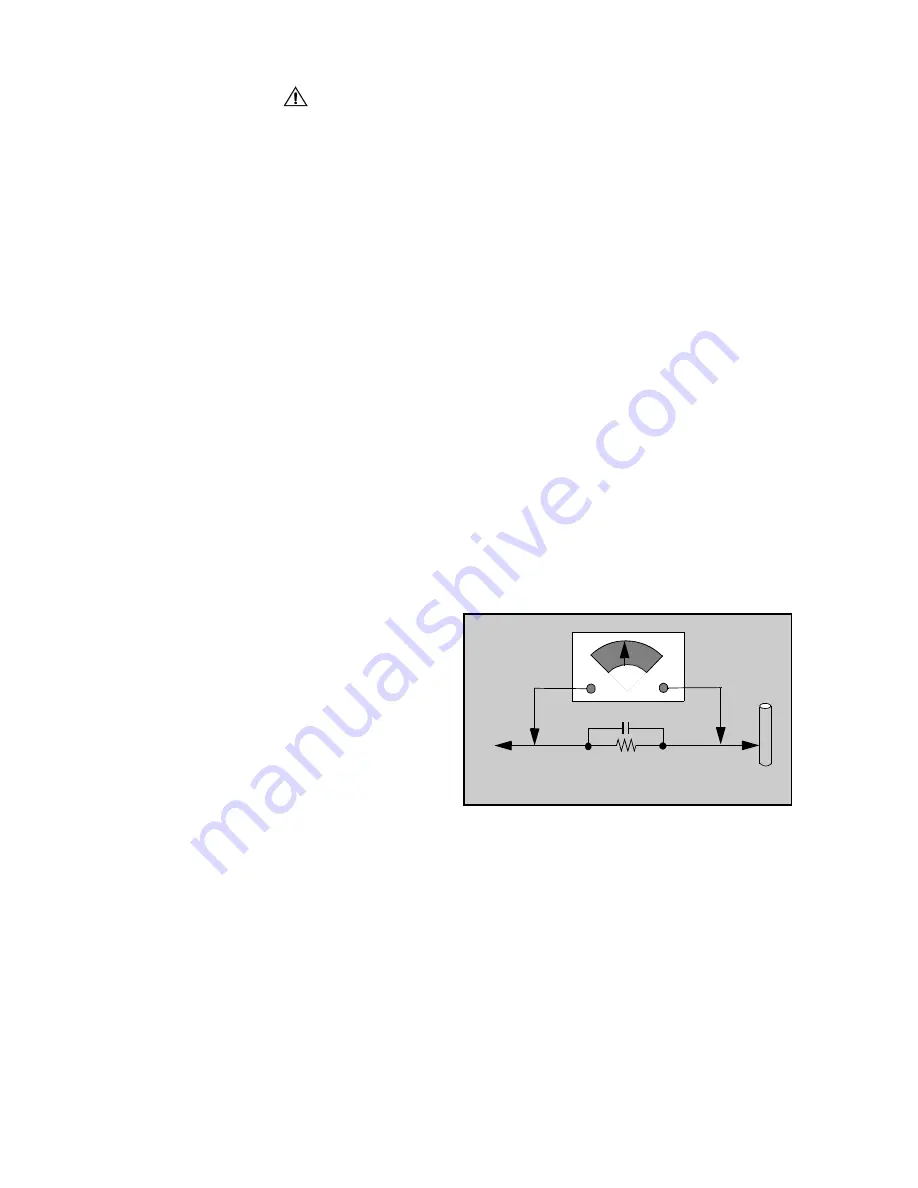

Leakage Current Hot Check

(Fig. 1)

Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer during the check.

Connect a 1.5k

Ω

10 watt resistor in parallel with a

0.15

µ

F capacitor between an exposed metallic part

and ground. Use earth ground, for example a

water pipe.

Using a DVM with a 1000 ohms/volt sensitivity or

higher, measure the AC potential across the resistor.

Repeat the procedure and measure the voltage

present with all other exposed metallic parts.

Verify that any potential does not exceed 0.75 volt

RMS. A leakage current tester (such a Simpson Model

229, Sencore Model PR57 or equivalent) may be used

in the above procedure, in which case any current

measure must not exceed 1/2 milliamp. If any

measurement is out of the specified limits, there is a

possibility of a shock hazard and the Receiver must be

repaired and rechecked before it is returned to the

customer.

X-ray Radiation

WARNING: The potential source of X-ray radiation in the

TV set are the High Voltage section and the picture tube.

Refer to X-RAY PROTECTON CIRCUIT CHECK in

Service Notes in this manual to confirm HHS Voltage.

High Voltage (CRT Anode)

Confirm Anode voltage is within limits:

Set the BRIGHTNESS, PICTURE, SHARPNESS and

COLOR to minimum (To obtain a dark image). Measure

High Voltage. It should be:

26.60±1.25kV for CT-20R6E/CE, CT-20G6E/DE,

and 27.70±1.25kV for CT-2016SE,

CT-2006SE, CT-20D11E/DE

.

If the upper limit is out of tolerance, immediate service

and correction is required.

Note: It is important to use an accurate, calibrated

high voltage meter.

0.15

µ

F

COLD

WATER

PIPE

(GROUND)

TO

INSTRUMENT’S

EXPOSED METAL

PARTS

1500

Ω

,10 W

AC VOLTMETER

Figure 1. Hot Check Circuit

Summary of Contents for CT-20R6CE

Page 55: ... 55 ...