- 5 -

Service notes

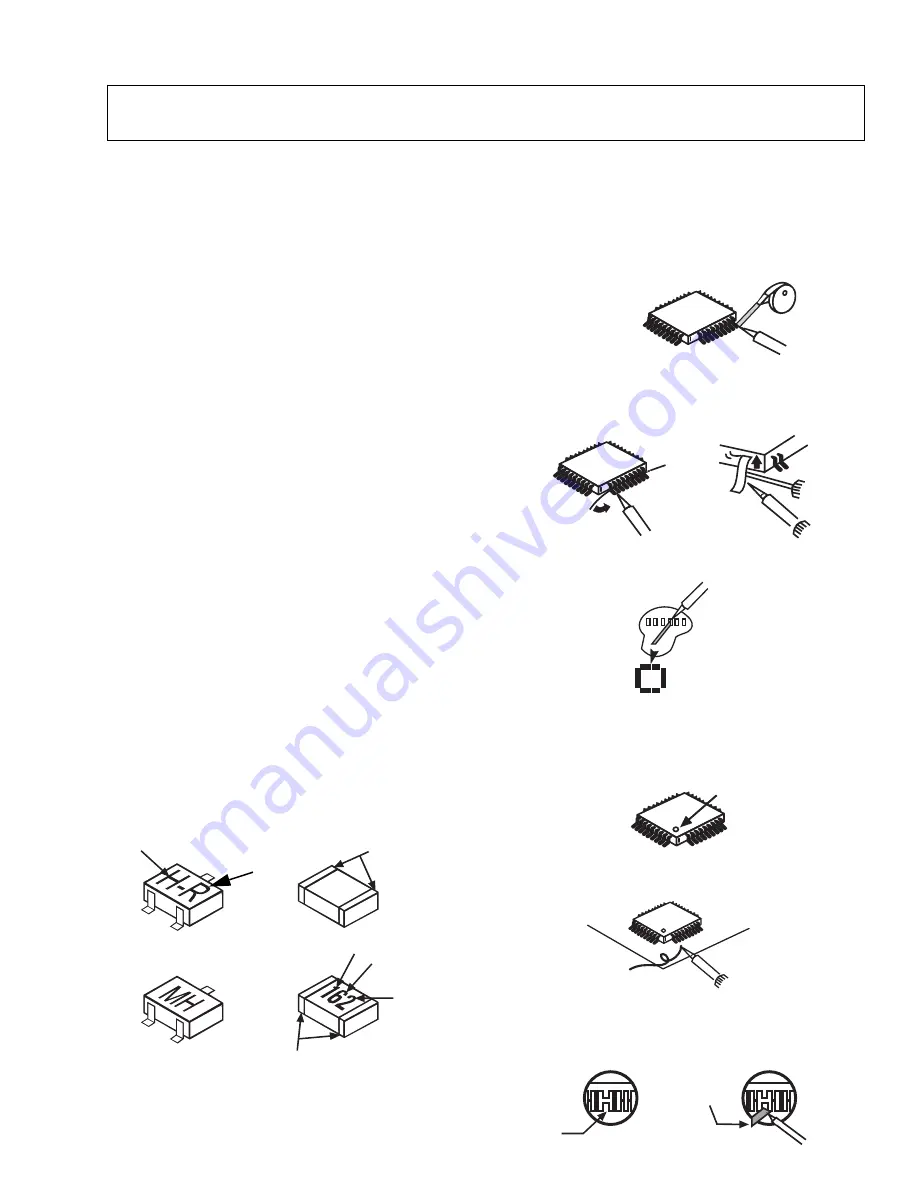

Leadless chip component

(surface mount)

Chip components must be replaced with identical chips

due to critical foil track spacing. There are no holes in

the board to mount standard transistors or diodes.

Some chips capacitor or resistor board solder pads

may have holes through the board, however the hole

diameter limits standard resistor replacement to 1/8

watt. Standard capacitor may also be limited for the

same

reason.

It

is

recommended

that

identical

components be used.

Chip resistor have a three digit numerical resistance

code - 1st and 2nd significant digits and a multiplier.

Example: 162 = 1600 or 1.6k

Ω

resistor, 0 = 0

Ω

(jumper).

Chip capacitors generally do not have the value

indicated on the capacitor. The color of the component

indicates the general range of the capacitance.

Chip transistors are identified by a two letter code. The

first letter indicates the type and the second letter, the

grade of transistor.

Chip diodes have a two letter identification code as per

the code chart and are a dual diode pack with either

common anode or common cathode. Check the parts

list for correct diode number.

Component removal

1.

Use solder wick to remove solder from component

end caps or terminal.

2.

Without pulling up, carefully twist the component

with tweezers to break the adhesive.

3.

Do

not

reuse

removed

leadless

or

chip

components since they are subject to stress

fracture during removal.

Chip component installation

1.

Put a small amount of solder on the board

soldering pads.

2.

Hold the chip component against the soldering

pads with tweezers or with a miniature alligator clip

and apply heat to the pad area with a 30 watt iron

until solder flows. Do not apply heat for more than

3 seconds.

How to replace Flat-IC

- Required Tools -

1.

Remove the solder from all of the pins of a Flat-IC

by using a de-solder braid.

2.

Put the iron wire under the pins of the Flat-IC and

pull it in the direction indicated while heating the

pins using a soldering iron. A small awl can be

used instead of the iron wire.

3.

Remove the solder from all the pads of the Flat-IC

by using a de-solder braid.

4.

Position the new Flat-IC in place (apply the pins of

the Flat-IC to the soldering pads where the pins

need to be soldered). Properly determine the

positions of the soldering pads and pins by

correctly aligning the polarity symbol.

5.

Solder all pins to the soldering pads using a fine

tipped soldering iron.

6.

Check with a magnifier for solder bridge between

the pins or for dry joint between pins and soldering

pads. To remove a solder bridge, use a de-solder

braid as shown in the figure below.

Note:

These components are affixed with glue. Be careful not to break or damage any foil under the

component or at the pins of the ICs when removing. Usually applying heat to the component for a

short time while twisting with tweezers will break the component loose.

c

b

e

Chip components

TRANSISTOR

CAPACITOR

RESISTOR

MH DIODE

SOLDER

CAPS

SOLDER

CAPS

1ST DIGIT

2ND DIGIT

MULTIPLIER

=1600 = 1.6k

GRADE

TYPE

COMMON

ANODES

CATHODE

•

Soldering iron

•

De-solder braids

•

Iron wire or small awl

•

Magnifier

Flat-IC

De-Solder

braid

Pull

Iron

wire

Awl

Soldering

iron

Soldering

iron

Soldering

iron

De-Solder

braid

Flat IC

123.....

Polarity symbol

Soldering

iron

Solder

De-Solder

braid

Solder

bridge

Soldering

iron

Summary of Contents for CT-32SC13-1G

Page 63: ... 50 A Board ...

Page 65: ... 52 ERJ6GEYJ183V NP2AH037AC ERENCES A Board ...

Page 66: ... 53 A Board ...

Page 69: ... 56 D Board ...

Page 70: ... 57 D Board ...

Page 71: ... 58 D Board ...

Page 74: ... 61 notes NOTES ...

Page 75: ... 62 G Board ...

Page 76: ... 63 G Board ...

Page 77: ... 64 G Board ...

Page 79: ... 66 L Board ...

Page 80: ... 67 L Board ...

Page 81: ... 68 A PCB ...

Page 82: ... 69 A PCB ...

Page 83: ... 70 D PCB ...

Page 84: ... 71 D PCB ...

Page 85: ... 72 G PCB ...

Page 86: ... 73 G PCB ...

Page 87: ... 74 L PCB ...

Page 88: ... 75 notes NOTES ...