- 15 -

Purity and convergence procedure

Adjustment is necessary only if the CRT or the

deflection yoke is replaced or if the setting was

disturbed. The complete procedure consists of:

1.

Vertical raster shift adjustment. (Only for models

with purity/convergence assembly with 4 pairs

of rings).

2.

Initial static convergence.

3.

Setting the purity.

4.

Final static convergence.

When the CRT or the yoke is replaced

Place the yoke on the CRT neck (do not tighten

the clamp).

Place the vertical raster shift tabs at 3 o’clock (90

o

from

the purity and convergence tabs)

Turn the receiver ON. Operate the receiver for 60

minutes using the first purity check field (white screen)

to stabilize the CRT.

Fully degauss the receiver by using an external

degaussing coil.

Slide the deflection yoke back and forth on the neck of

the CRT until it produces a near white, uniform raster.

Vertical raster shift adjustment

(only for models with purity/convergence assembly

with 4 pairs of rings).

Apply a green pattern with a horizontal line, adjust the

deflection yoke so that has no tilt, then secure it.

Adjust center line of the pattern with the mechanical

center of the CRT, this center is determined by two

marks at the side edges of the screen. To adjust the

line, once the vertical raster shift tabs are place at 3

o’clock to reduce its magnetic field effect (see Fig. 9

and Fig. 10) open the tabs the same angle from the

center, until the center line of the pattern becomes a

straight line, centered with the marks of the CRT.

(see Fig. 11)

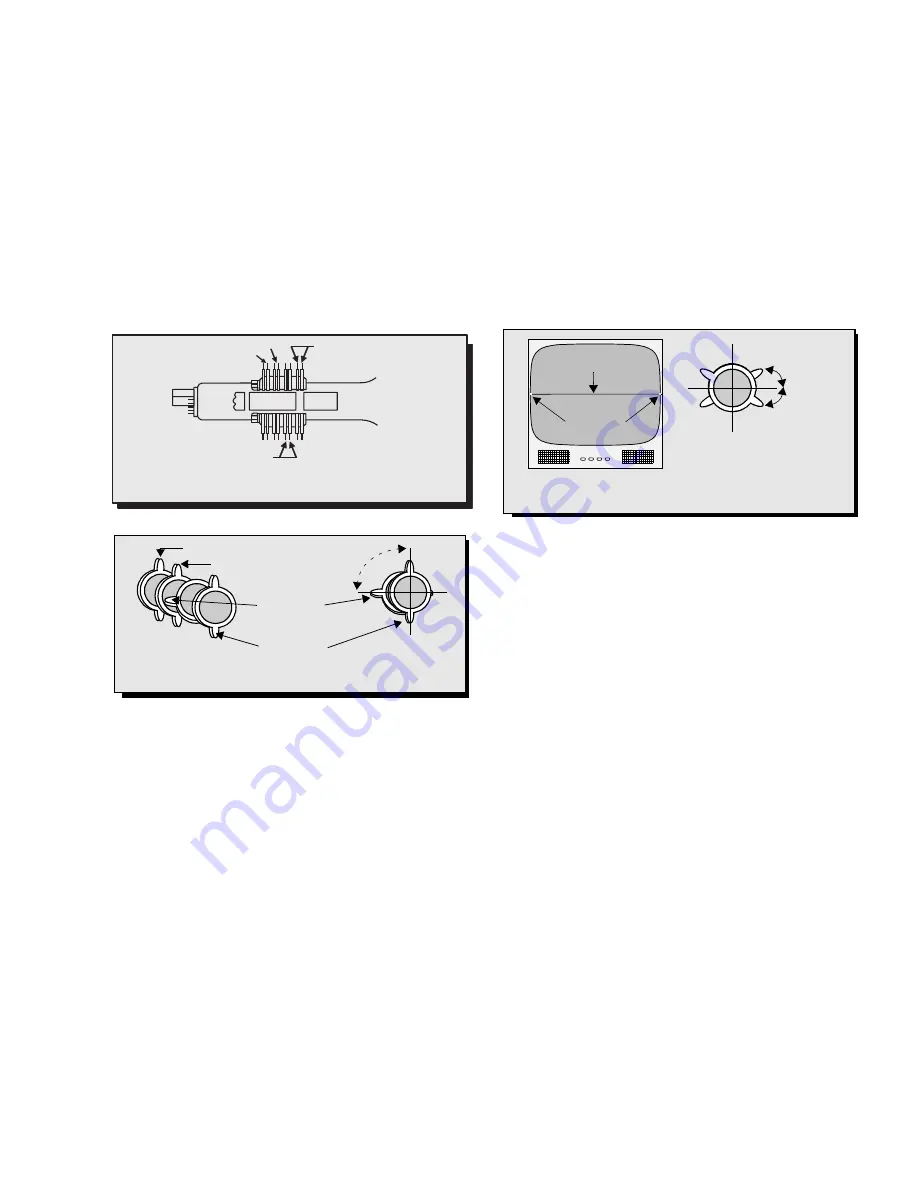

G3

G4

Purity Rings Centered

Over G3/G4 Gap

R&B Convergence Rings

R&B&G Convergence Rings

Vertical Raster Shift Ring

Figure 9.

Positioning of purity/convergence assembly

(4 pairs of rings)

90

o

Purity rings

Vertical raster

R&B Convergence rings

R&B&G Convergence rings

Figure 10.

Positioning of purity/convergence

assembly (4 pairs of rings)

shift rings

Vertical raster shift tabs

Open the

same angle

from center

Figure 11.

Vertical raster shift adjustment

(4 pairs of rings assembly)

Center Marks

from pattern

Center line

Mechanical

Summary of Contents for CT-32SX12CF

Page 50: ... 50 A Board ...

Page 52: ... 52 ERJ6GEYJ183V NP2AH037AC ERENCES A Board ...

Page 53: ... 53 A Board ...

Page 56: ... 56 D Board ...

Page 57: ... 57 D Board ...

Page 58: ... 58 D Board ...

Page 61: ... 61 notes NOTES ...

Page 62: ... 62 G Board ...

Page 63: ... 63 G Board ...

Page 64: ... 64 G Board ...

Page 66: ... 66 L Board ...

Page 67: ... 67 L Board ...

Page 68: ... 68 A PCB ...

Page 69: ... 69 A PCB ...

Page 70: ... 70 D PCB ...

Page 71: ... 71 D PCB ...

Page 72: ... 72 G PCB ...

Page 73: ... 73 G PCB ...

Page 74: ... 74 L PCB ...

Page 75: ... 75 notes NOTES ...