1. Safety Precautions

The following is intended for the person responsible for installing or servicing the Solenoid Valve

Controller. Before conducting installation or electrical work, be sure to carefully read these

“Safety Precautions”. Follow instructions exactly in all installation or electrical work.

The precautions given in this manual consist of specific “Warnings” and “Cautions”. They provide

important safety related information and are important for your safety, the safety of others, and

troublefree operation of the system. Be sure to strictly observe all safety procedures. The labels and

their meanings are as described below.

This symbol refers to a hazard or unsafe procedure or practice which can result in

severe personal injury or death.

Warning

Caution

This symbol refers to a hazard or unsafe procedure or practice which can result in

personal injury or product or property damage.

Warning

Be sure to arrange installation at the dealer where the system was purchased or use a professional

installer.

Leaks, electric shock or fire may result if an inexperienced person performs any installation or wiring

Be sure to turn off the power source circuit breaker of the unit before installation or wiring.

High electrical voltages used in the unit may cause electric shock.

procedures incorrectly.

Only a qualified electrician should attempt to install this system, in accordance with the provisions of

the Technical standards for Electrical Installations, local regulations for indoor wirings and these

“Installation (Electric) and Service Instructions”. Be sure to use a dedicated electrical circuit.

Insufficient electrical circuit capacity may cause electric shock or fire.

Use the specified cables (type and wiring diameter) for the electrical connections, and securely connect

the cables. Run and fasten the cables securely so that external forces or pressure placed on the cables

will not be transmitted to the connection terminals. Overheating or fire may result if connections or

attachments are not secure.

Install in a location that is fully strong enough to support the weight of the unit. If it is not strong enough,

the unit may fall, resulting in injury.

Ventilate the work area if cooling gas leaks during installation. Poisonous gas can result if cooling gas

comes into contact with fire.

After installation, check to be sure that there are no gas leaks.

Poisonous gas can result if cooling gas leaks into the room and comes into contact with a fan heater,

stove, range, or other source of fire.

Caution

Do not install in a location subject to leakage of flammable gasses.

Fire can result if gas builds up around the unit.

①

Solenoid Valve Control PCB

②

Power cables

③

Signal output cables

3P Yellow

3P White

5P Black

6P White

2. Supplied Parts

3. Wiring Diagram

・

Connect to the indoor control PCB with

Power cable (Supplied part

②

) and Signal output cable (Supplied part

③

)

・

The connected solenoid valve is a solenoid valve kit.

POWER

CN309

OP1

3P (Yellow)

Power cables (Supplied part

②

)

CN002

POWER

3P (White)

[AC Power Input]

CN003

9P (Red)

[Solenoid valve output]

Optional parts

Solenoid valve kit

DC12V

EP valve

Balance valve

Intake valve

Output valve

5P (Black)

Indoor control PCB

CN001

OPTION/3WAY

6P (White)

Signal output

cables (Supplied part

③

)

CN81

3WAY

Solenoid Valve Control PCB (Supplied part

①

)

r. (Fig.1)

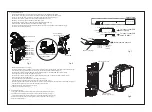

4. Installation

1.

How to remove the grille

・

Remove the two screw covers bellow the grille and open the front panel. (Fig.1)

・

Remove the six screws. (Fig.1)

・

Remove the terminal block cove

・

Warp the lower flap to take out the pins and remove the lower flap. (Fig.2)

・

Hold the both sides of the grille and pull upwards to remove from the frame. (Fig.3)

・

Remove the electrical component box cover. (Fig.4)

Protective ground screw

Fig.3

Tab

Frame

Fig.4

Electrical component

box cover

Upper tab

Lower tab

Electrical component box

Grille

Screw (on the front)

Screw (on the cover)

Front panel

Screw (on the bottom)

Screw

Bottom surface

Screw cover

T

erminal block cover

Fig.1

Grille

Upper flap

Lower flap

Pin

Fig.2

Solenoid Valve

Installation (Electric) and Service Instructions

Controller(CZ-CAPEK2)