626

JAN 2006

Ver. 5.2

DP-3510/3520/3530/4510/4520/4530/6010/6020/6030

4. Adjusting the Buffer Roller Winding Amount

Perform this adjustment in the following instances:

(1) When the Finisher Controller PCB or the EEPROM (Q2) on the Finisher Controller PCB has been

replaced.

(2) When something causes the winding amount to fluctuate

The “winding amount” is the amount of difference between the 1st and 2nd sheets wound onto the

Buffer Roller Device in the freed direction.

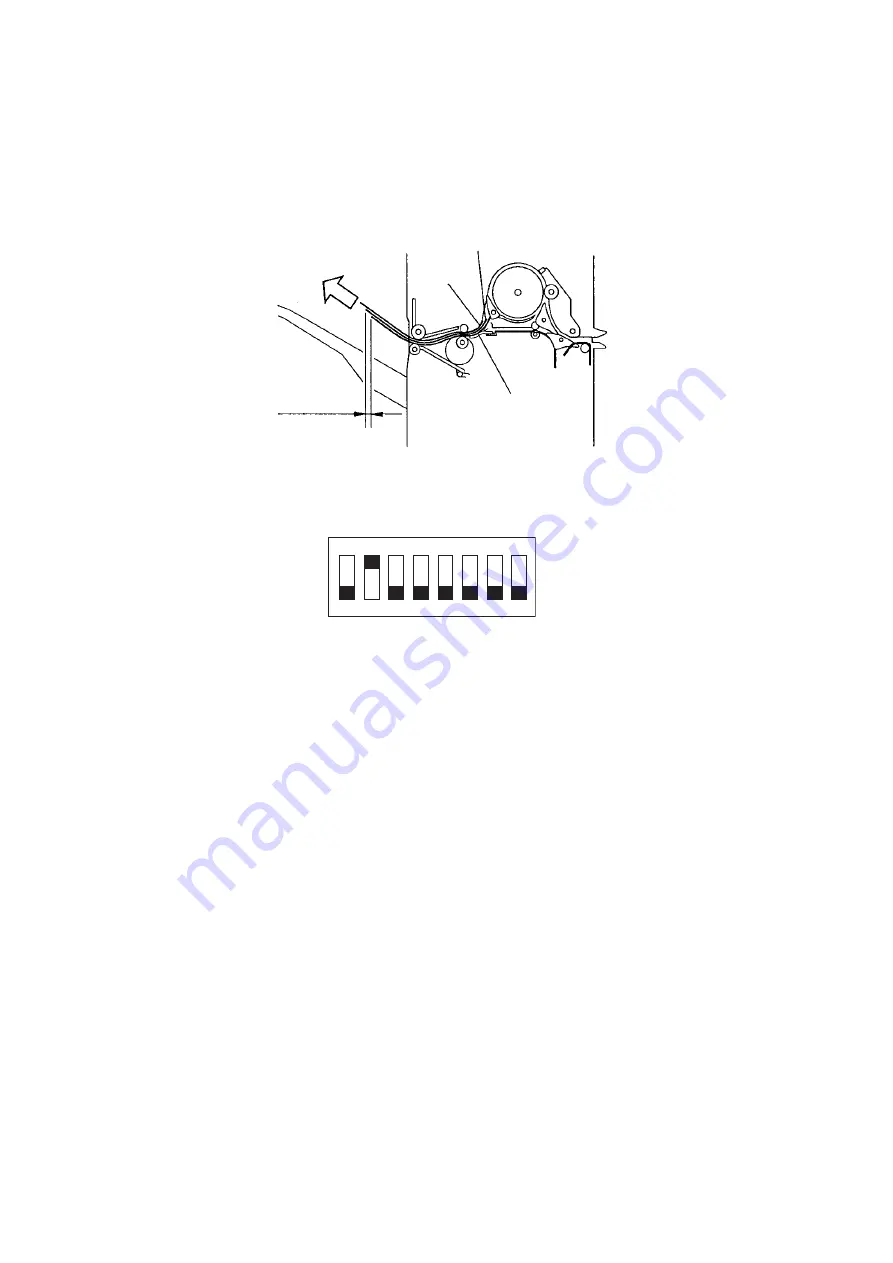

Fig. 7-007

a. Set SW3 on the Finisher Controller PCB as indicated.

Fig. 7-008

b. Turn the Copier OFF then back ON again.

c. Set the mode setting on the Copier to “1” and the number of originals (A4 or LTR) to “3” in the staple

mode.

d. Press the copy start key.

• Copying starts, three sheets for the first copy are output as a stack on the Staple Tray, and copying

stops with the copies held at the Exit Roller.

e. Remove the stack of sheets from the Finisher exit taking care to prevent the offset of the output

sheets from changing.

Paper exit direction

2nd sheet

3rd sheet

1st sheet

Winding

amount

1

ON

2

3

4

5

6

7

8

Summary of Contents for DP-3530

Page 4: ...4 Beispiel DP 6530 4530 6030 Hinweis ...

Page 424: ...424 JAN 2006 Ver 5 2 DP 3510 3520 3530 4510 4520 4530 6010 6020 6030 ...

Page 425: ...425 JAN 2006 Ver 5 2 DP 3510 3520 3530 4510 4520 4530 6010 6020 6030 ...

Page 474: ...474 JAN 2006 Ver 5 2 DP 3510 3520 3530 4510 4520 4530 6010 6020 6030 memo ...

Page 842: ...memo ...

Page 858: ...DZZSM00298 ...