3. TROUBLESHOOTING GUIDE

Refer to WIRING CONNECTION DIAGRAM.

Replace MOTOR HEATER ASSEMBLY

< TROUBLE >

< CHECK >

< REMEDY >

Main body is

not operated

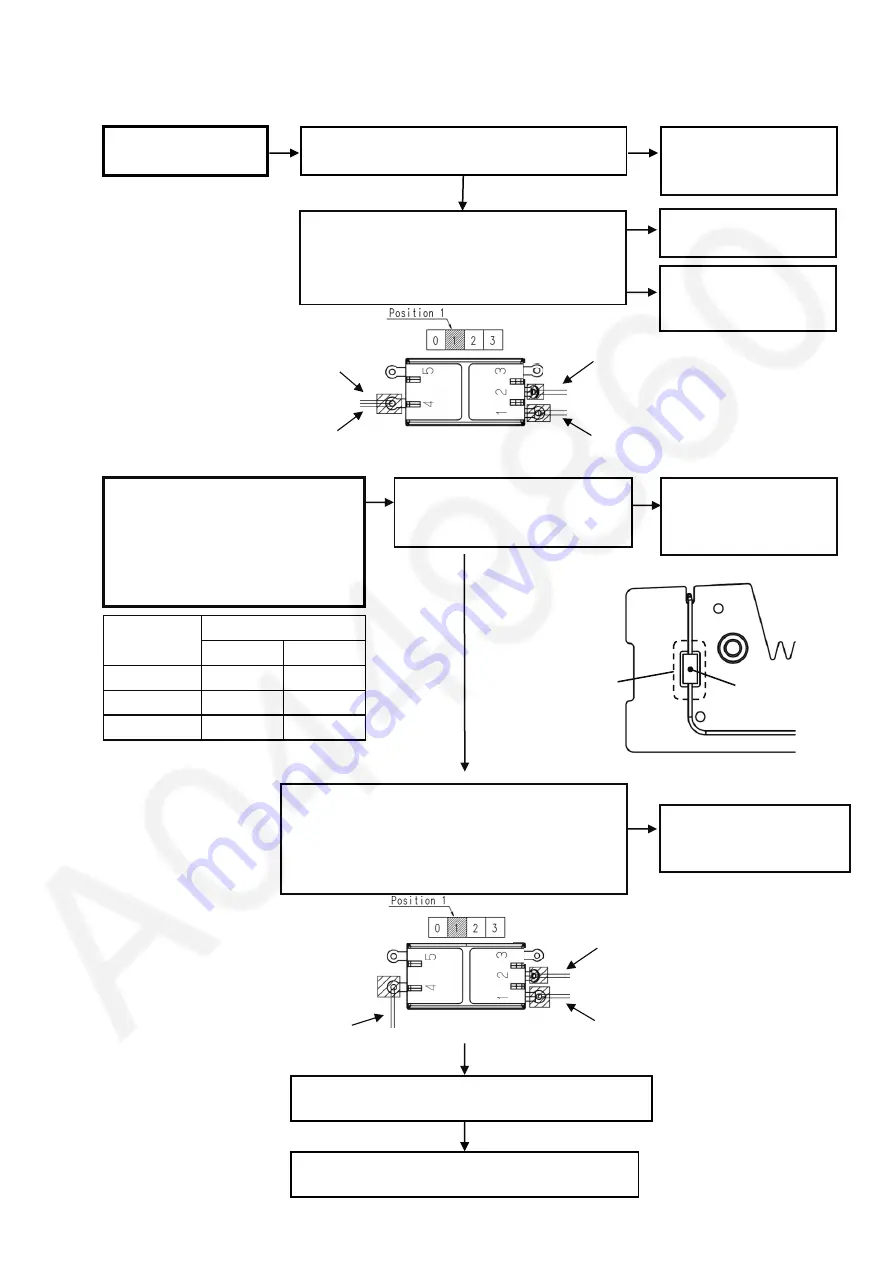

<CHECK POWER CORD>

Check the conductivity of power cord

<CHECK MAIN SWITCH>

Check the conductivity between the terminal 1

and 4 by setting

the MAIN SWITCH to Position 1

(Figure 1)

Replace the

MAIN SWITCH

Replace the

MOTOR HEATER

ASSEMBLY

NG

OK

NG

OK

Replace the

MOTOR HEATER

ASSEMBLY

Lead Wire (Yellow)

Lead Wire (Red)

Lead Wire (Gray)

Lead Wire (Orange)

Main Switch

Figure 1

Control point

Thermistor must

be placed at

the center of hole

Thermistor

<CHECK TEMPERATURE SWITCH>

Check the conductivity between the terminal 1

and 4 by setting

the TEMPERATURE SWITCH to Position 1

(Figure 4)

Replace the

TEMPERATURE SWITCH

NG

Figure 4

Replace PRINTED CIRCUIT ASSEMBLY

OK

Figure 2

For EH-NE82 and 84 only

Advance heat protection mode is not

operated or not operated follow spec

(Figure 2)

*Air keep switching between hot and cold

<

CHECK THERMISTOR>

Check the position of thermistor

(Figure 3)

Adjust the position

of thermistor follow

control point

NG

OK

Figure 3

Environmental

Interval time (sec)

29.1

º

C or more 2.0 ~ 4.5

5.0 ~ 8.0

temperature

Hot air

Cold air

23.9

º

C or less

3.0 ~ 8.0

2.0 ~ 4.5

24 ~ 29

º

C

2.0 ~ 6.0

2.0 ~ 5.5

*Check interval time after operate on this mode for 30 sec

OK

Lead Wire (Black)

Lead Wire (Brown)

Lead Wire (Orange)

Temperature switch

Summary of Contents for EH-NE84

Page 12: ...5 Wiring Connection Diagram ...