1-12-2-2-8

1

For the flare nuts at tubing connections, be sure to use the

flare nuts that were supplied with the unit, or else flare nuts

for R410A, R32 (type 2). The refrigerant tubing that is used

must be of the correct wall thickness as shown in the table

below.

Tube diameter

Tightening torque

(approximate)

Tube thickness

ø6.35 (1/4")

14 – 18 N · m

{140 – 180

kgf

· cm}

0.8 mm

ø9.52 (3/8")

34 – 42 N · m

{340 – 420

kgf

· cm}

0.8 mm

ø12.7 (1/2")

49 – 55 N · m

{490 – 550

kgf

· cm}

0.8 mm

ø15.88 (5/8")

68 – 82 N · m

{680 – 820

kgf

· cm}

1.0 mm

Because the pressure is approximately 1.6 times higher

than conventional refrigerant R22 pressure, the use of

ordinary flare nuts (type 1) or thin-walled tubes may result

in tube rupture, injury, or asphyxiation caused by refrigerant

leakage.

In order to prevent damage to the flare caused by over-

tightening of the flare nuts, use the table above as a guide

when tightening.

When tightening the flare nut on the liquid tube, use an

adjustable wrench with a nominal handle length of 200 mm.

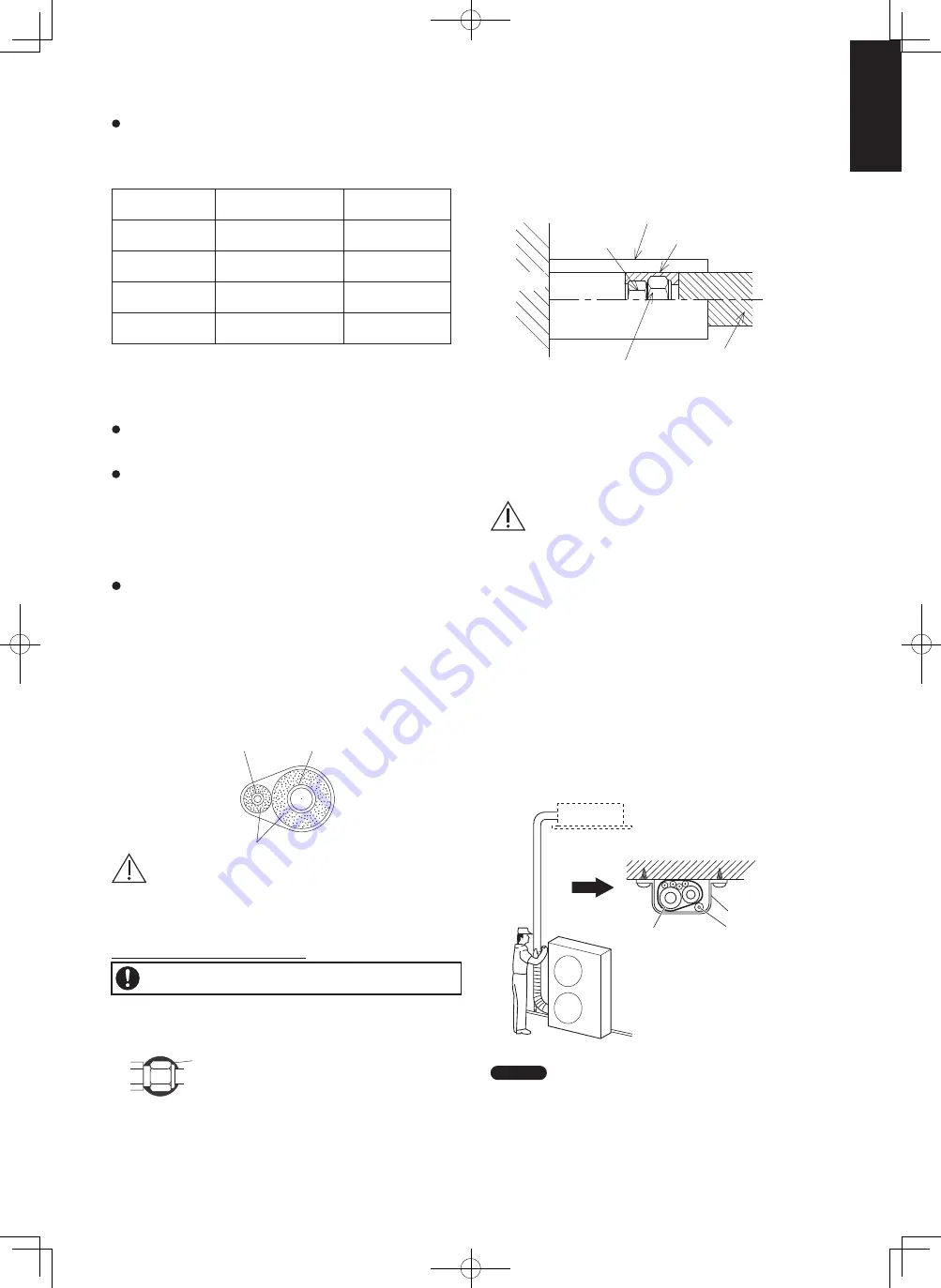

Insulating the Refrigerant Tubing

Tubing Insulation

Must ensure that pipe-work shall be protected from physical

damage.

Thermal insulation must be applied to all units tubing,

including distribution joint (field supply).

* For gas tubing, the insulation material must be heat

resistant to 120°C or above. For other tubing, it must be

heat resistant to 80°C or above.

Insulation material thickness must be 10 mm or greater.

If the conditions inside the ceiling exceed DB 30°C and RH

70%, increase the thickness of the gas tubing insulation

material by 1 step.

Two tubes arranged together

Liquid tubing

Gas tubing

Insulation

CAUTION

If the exterior of the outdoor unit valves has been finished

with a square duct covering, make sure you allow sufficient

space to access the valves and to allow the panels to be

attached and removed.

T

aping the flare

nuts

Wind the white insulating tape around the flare nuts at the gas

tube connections. Then cover up the tubing connections with

the flare insulator, and fill the gap at the union with the supplied

black insulating tape. Finally, fasten the insulator at both ends

with the supplied vinyl clamps.

Flare insulator (supplied)

Insulating tape

(supplied)

Tube insulator

(not supplied)

Heat resistant

120°C or above

Flare union

Flare nut

Unit side

Insulation material

The material used for insulation must have good insulation

characteristics, be easy to use, be age resistant, and must not

easily absorb moisture.

CAUTION

After a tube has been insulated, never try to bend it into

a narrow curve because it can cause the tube to break or

crack.

Never grasp the drain or refrigerant connecting outlets

when moving the unit.

Taping the Tubes

(1) At this time, the refrigerant tubes (and electrical wiring

if local codes permit) should be taped together with

armoring tape in 1 bundle. To prevent condensation from

overflowing the drain pan, keep the drain hose separate

from the refrigerant tubing.

(2) Wrap the armoring tape from the bottom of the outdoor

unit to the top of the tubing where it enters the wall. As you

wrap the tubing, overlap half of each previous tape turn.

(3) Clamp the tubing bundle to the wall, using 1 clamp approx.

each meter.

Insulated tubes

Drain hose

Clamp

NOTE

Do not wind the armoring tape too tightly since this will

decrease the heat insulation effect. Also ensure that the

condensation drain hose splits away from the bundle and drips

clear of the unit and the tubing.

Ensure to do the re-flaring of pipes before connecting to units to

avoid leaking.

Insulation material and silicone sealant. Please ensure

there are no gaps where moisture can enter the joint.

To prevent the ingress of moisture into the joint which could have the

Additional Precautions For R32 Models.

potential to freeze and then cause leakage, the joint must be sealed

with suitable silicone and insulation material. The joint should be sealed

on both liquid and gas side.

Silicone Sealant must be neutral cure and ammonia free. Use of silicon

containing ammonia can lead to stress corrosion on the joint and cause

leakage.

SM830276-00_欧州向け R32シングル TD&SM.indb 8

2019/02/27 11:54:55

Summary of Contents for Elite Big PAC-i S-200PE3E5B

Page 12: ...MEMO Xi SM830276 00_ R32 TD SM indb 12 19 02 26 15 26 22...

Page 160: ...1 14 8 MEMO SM830276 00_ R32 TD SM indb 8 2019 02 27 11 55 39...

Page 176: ...MEMO 2 16 SM830276 00_ R32 TD SM indb 16 19 02 28 13 23 00...

Page 182: ...MEMO 3 6 SM830276 00_ R32 TD SM indb 6 19 02 26 10 39 17...

Page 238: ...MEMO 5 38 SM830276 00_ R32 TD SM indb 38 19 02 28 13 29 52...

Page 316: ...201903 SM830276 00_ R32 TD SM indb 1 19 02 15 8 52 12...