1-12-2-2-32

1

SERVICING

CAUTION

IMPORTANT INFORMATION REGARDING THE REFRIGERANT USED

NOTE

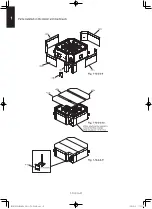

See “

■

Outdoor Unit” under the Section 1-12. Installation Instructions.

Any qualified person who is involved with working on or breaking into a refrigerant circuit should hold a current valid certificate

from an industry-accredited assessment authority, which authorizes their competence to handle refrigerants safely in

accordance with an industry recognised assessment specification.

Servicing shall only be performed as recommended by the equipment manufacturer. Maintenance and repair requiring the

assistance of other skilled personnel shall be carried out under the supervision of the person competent in the use of flammable

refrigerants.

Servicing shall be performed only as recommended by the manufacturer.

Prior to beginning work on systems containing flammable refrigerants, safety checks are necessary to ensure that the risk of

ignition is minimised. For repair to the refrigerating system, (2) to (6) shall be completed prior to conducting work on the system.

(1) Work shall be undertaken under a controlled procedure so as to minimise the risk of a flammable gas or vapour being present

while the work is being performed.

(2) All maintenance staff and others working in the local area shall be instructed on the nature of work being carried out. Work in

confined spaces shall be avoided. The area around the workspace shall be sectioned off. Ensure that the conditions within the

area have been made safe by control of flammable material.

(3) The area shall be checked with an appropriate refrigerant detector prior to and during work, to ensure the technician is aware

of potentially toxic or flammable atmospheres. Ensure that the leak detection equipment being used is suitable for use with all

applicable refrigerants, i.e. non-sparking, adequately sealed or intrinsically safe.

(4) If any hot work is to be conducted on the refrigeration equipment or any associated parts, appropriate fire extinguishing

equipment shall be available to hand. Have a dry powder or CO

2

fire extinguisher adjacent to the charging area.

(5) No person carrying out work in relation to a refrigeration system which involves exposing any pipe work shall use any sources

of ignition in such a manner that it may lead to the risk of fire or explosion. All possible ignition sources, including cigarette

smoking, should be kept sufficiently far away from the site of installation, repairing, removing and disposal, during which

refrigerant can possibly be released to the surrounding space. Prior to work taking place, the area around the equipment is to

be surveyed to make sure that there are no flammable hazards or ignition risks. “No Smoking” signs shall be displayed.

(6) Ensure that the area is in the open or that it is adequately ventilated before breaking into the system or conducting any hot

work. A degree of ventilation shall continue during the period that the work is carried out. The ventilation should safely disperse

any released refrigerant and preferably expel it externally into the atmosphere.

(7) Where electrical components are being changed, they shall be fit for the purpose and to the correct specification. At all times

the manufacturer’s maintenance and service guidelines shall be followed. If in doubt, consult the manufacturer’s technical

department for assistance.

•

The charge size is in accordance with the room size within which the refrigerant containing parts are installed.

•

The ventilation machinery and outlets are operating adequately and are not obstructed.

•

Marking to the equipment continues to be visible and legible. Markings and signs that are illegible shall be corrected.

•

Refrigeration pipe or components are installed in a position where they are unlikely to be exposed to any substance which

may corrode refrigerant containing components, unless the components are constructed of materials which are inherently

resistant to being corroded or are suitably protected against being so corroded.

(8) Repair and maintenance to electrical components shall include initial safety checks and component inspection procedures. If a

fault exists that could compromise safety, then no electrical supply shall be connected to the circuit until it is satisfactorily dealt

with. If the fault cannot be corrected immediately but it is necessary to continue operation, an adequate temporary solution shall

be used. This shall be reported to the owner of the equipment so all parties are advised.

Initial safety checks shall include:

•

• That capacitors are discharged. This shall be done in a safe manner to avoid possibility of sparking.

That no live electrical components and wiring are exposed while charging, recovering or purging the system.

•

That there is continuity of earth bonding.

During repairs to sealed components, all electrical supplies shall be disconnected from the equipment being worked upon prior

to any removal of sealed covers, etc.

Particular attention shall be paid to the following to ensure that by working on electrical components, the casing is not altered

in such a way that the level of protection is affected. This shall include damage to cables, excessive number of connections,

terminals not made to original specification, damage to seals, incorrect fitting of glands, etc.

Ensure that apparatus is mounted securely.

Ensure that seals or sealing materials have not degraded such that they no longer serve the purpose of preventing the ingress

of flammable atmospheres.

Replacement parts shall be in accordance with the manufacturer’s specifications.

NOTE:

The use of silicon sealant may inhibit the effectiveness of some types of leak detection equipment. Intrinsically safe

components do not have to be isolated prior to working on them.

Do not apply any permanent inductive or capacitance loads to the circuit without ensuring that this will not exceed the

permissible voltage and current permitted for the equipment in use.

Intrinsically safe components are the only types that can be worked on while live in the presence of a flammable atmosphere.

The test apparatus shall be at the correct rating.

Replace components only with parts specified by the manufacturer. Unspecified parts by manufacturer may result ignition of

refrigerant in the atmosphere from a leak.

SM830276-00_欧州向け R32シングル TD&SM.indb 32

2019/02/27 11:55:19

Summary of Contents for Elite Big PAC-i S-200PE3E5B

Page 12: ...MEMO Xi SM830276 00_ R32 TD SM indb 12 19 02 26 15 26 22...

Page 160: ...1 14 8 MEMO SM830276 00_ R32 TD SM indb 8 2019 02 27 11 55 39...

Page 176: ...MEMO 2 16 SM830276 00_ R32 TD SM indb 16 19 02 28 13 23 00...

Page 182: ...MEMO 3 6 SM830276 00_ R32 TD SM indb 6 19 02 26 10 39 17...

Page 238: ...MEMO 5 38 SM830276 00_ R32 TD SM indb 38 19 02 28 13 29 52...

Page 316: ...201903 SM830276 00_ R32 TD SM indb 1 19 02 15 8 52 12...