7

7

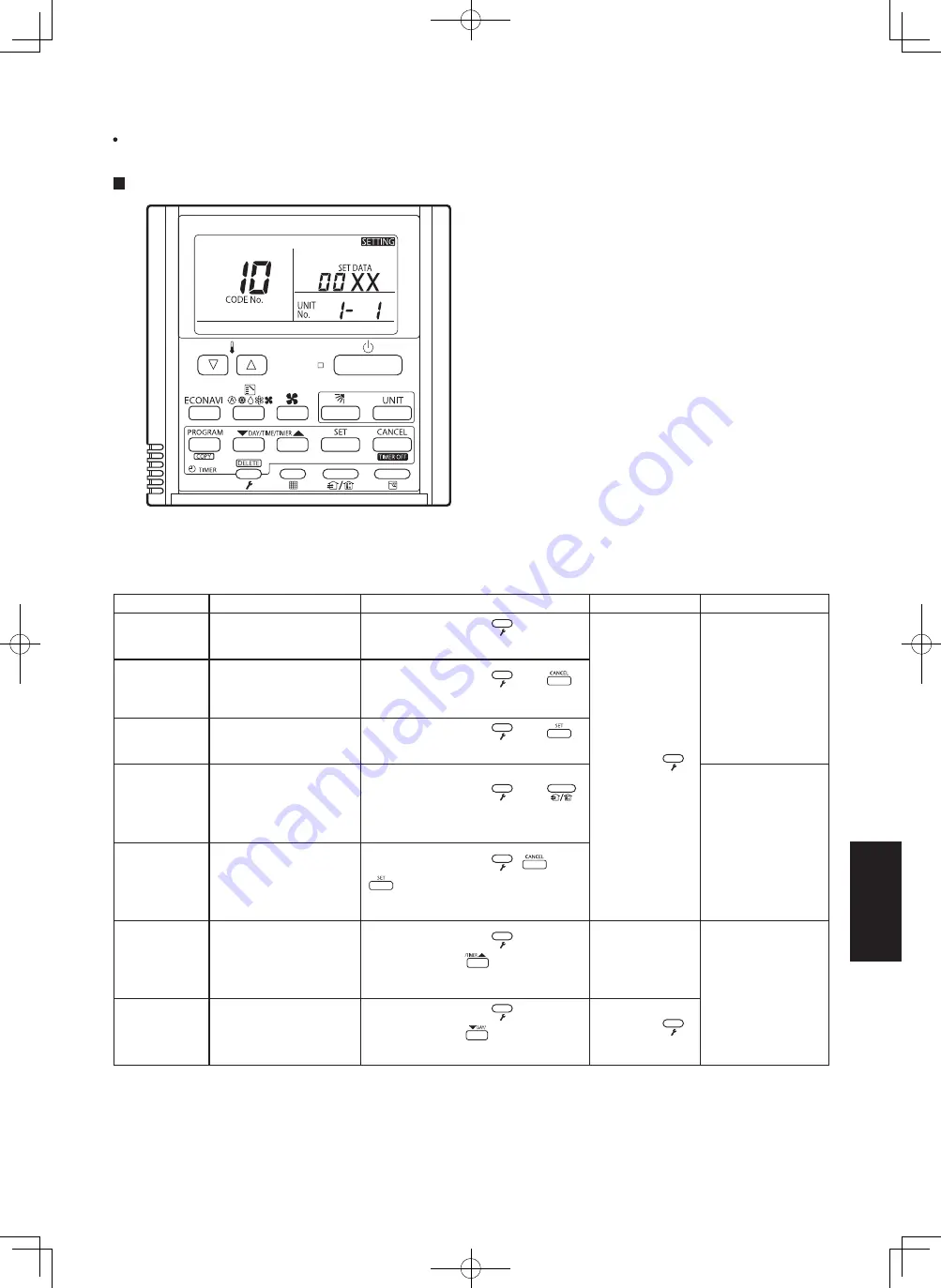

7-7. Remote Controller Servicing Functions

Optional Controller

Remote Controller Functions

1. Remote Controller Servicing Functions

Functions

Description

Button operation

Reset operation

Unit status

Test run

Operation with forced

thermostat ON

Press the

button.

Current operation

is maintained.

Sensor

temperature

display

Temperature display

from each sensor

Servicing

check display

Alarm history display

Simple

settings

Filter lifetime, operating

mode priority, central

control address, and

other settings

When settings

are made from a

remote controller,

the indoor unit

where that remote

controller is

connected stops.

Detailed

settings

System address, indoor

unit address, central

control address, and

other settings

Automatic

address

Automatic address

setting based on

command from the

wired remote controller

Automatic reset

Entire system

stops.

Address

change

Change of indoor unit

address

Press the

button.

Press and hold the

button for

4 seconds or longer.

Press and hold the

and

buttons for 4 seconds or longer.

Press and hold the

and

buttons for 4 seconds or longer.

Press and hold the

,

and

buttons for 4 seconds or

longer.

Press and hold the

and

buttons for 4 seconds or longer.

Press and hold the

and the

timer operation

buttons for 4

seconds or longer.

Press and hold the

and the

timer operation

buttons for 4

seconds or longer.

The remote controller includes a number of servicing functions. Use these as needed for test runs and

inspections.

Fig. 7-6

Timer Remote Controller CZ-RTC4

List of Servicing Functions

<Procedure>

DC Fan Tap Change Procedure

It is necessary to set the fan speed in accordance with the intended application and the optional parts to be

used if any such part is used. (Table 1)

If this speed is not changed, a reduction in the air flow may result, causing the air outlet temperature to drop

and condensation to form during cooling.

There are two ways to set the fan speed: either (1) change the positions of the DIP switches on the indoor unit

control PCB or (2) set the speed using the wired remote controller. Select one of these ways.

* Priority is given to setting the fan speed by changing the positions of the DIP switches.

TP

6

TP

3

TP

1

1

ON

2 3

TP

6

TP

3

TP

1

1

ON

2 3

Intended application /

name of optional parts

Setting

No

(1)

Item code

5D/5d

setting data

0001

0000

Standard (factory setting)

High-ceiling setting 1

(with standard, ECONAVI panel)

Air-flow blocking kit

(when a duct is connected.)

Intended application /

name of optional parts

Setting

No

Item code

5D/5d

setting data

(3)

(6)

0003

0006

Air-flow blocking kit (for 3-way air flow)

High-ceiling setting 2

(with standard, ECONAVI panel)

Air-flow blocking kit

(for 2-way air flow)

<Procedure> Be absolutely sure to turn off the

power (earth-leakage circuit breaker).

<1> On Table 1, check out the “Setting No.” that

corresponds to the intended application and

the optional parts to be used.

<2> Open the cover of the electrical parts box, and

check the indoor unit control PCB. (Fig. 7-5)

<3> Select the Setting No. which was checked out

on Table 1, and change the positions of the

DIP switches on the indoor unit control PCB.

(1) When setting the fan speed by changing

the positions of the DIP switches on the

indoor unit control PCB

(2) When setting the fan speed using a wired remote controller

(optional parts: CZ-RTC5B)

“OFF” position

1 2 3

TP6

TP3

TP1

1

ON

2 3

DIP switch

DIP switch

Setting

No.

“OFF” position

“ON” position

DIP switch

“OFF” position

“ON” position

TP6

TP3

TP1

1

ON

2 3

DIP switch

“ON” position

TP6

TP3

TP1

ON

(3)

(6)

(1)

In the example

shown in the figure

above:

DIP switch 1 is OFF.

DIP switch 2 is ON.

DIP switch 3 is OFF.

On Table 1, check out the “Item code 5D setting data” that corresponds to the intended

application and the optional parts to be used.

(3) When setting the fan speed using a wired remote controller

(optional parts: CZ-RTC4)

On Table 1, check out the “Item code 5d setting data” that corresponds to the intended

application and the optional parts to be used.

<1> Hold down the + + buttons together for at least 4 seconds.

The maintenance function screen is displayed.

<2> Use the / buttons to select the display and the / buttons to

select the page.

Select “8.Detailed settings” and press the button.

The [Detailed settings screen] appears.

Using the / buttons, select the unit No.

<3> Using the / buttons, select the item code.

Using the / buttons, change the item code to “5D.”

<4> Using the / buttons, select the setting data.

Using the buttons, change the setting data to the value checked out

on Table 1, and press the button.

<5> After selecting the unit No. using the / buttons, press the button.

The [Detailed settings completion screen] appears. Select “Yes” , and press the

<1> Hold down the + + buttons together for at least 4 seconds.

<2> Each time the button is pressed, the numbers of the indoor units under group

control are displayed in sequence.

The fan motor of only the indoor unit that has been selected will run.

<3> Specify item code “5d” using the temperature setting / buttons.

<4> Change the setting data using the hour buttons. The setting data details

are as given on Table 1.

<5> Press the button. (OK if the display changes from flashing to lighted.)

<6> Press the button. The normal stop status is established.

Go to step <2> to change the selected indoor unit.

<7> Press the button. The normal stop status is established.

(1)

0001

5

Unit No.

Setting data

Item code

<Procedure> Ensure that the units have stopped operating before changing the fan speed.

<Procedure> Ensure that the unit has stopped operating before changing the fan speed.

DC fan motor tap setting table

(Table. 1)

Indoor unit control PCB

(Fig. 7-5)

SM830255-00_Single_欧州4方向 TD&SM.indb 18

16/09/21 13:54:53

7-17

SM830276-00_欧州向け R32シングル TD&SM.indb 17

19/02/28 13:33:41

Summary of Contents for Elite Big PAC-i S-200PE3E5B

Page 12: ...MEMO Xi SM830276 00_ R32 TD SM indb 12 19 02 26 15 26 22...

Page 160: ...1 14 8 MEMO SM830276 00_ R32 TD SM indb 8 2019 02 27 11 55 39...

Page 176: ...MEMO 2 16 SM830276 00_ R32 TD SM indb 16 19 02 28 13 23 00...

Page 182: ...MEMO 3 6 SM830276 00_ R32 TD SM indb 6 19 02 26 10 39 17...

Page 238: ...MEMO 5 38 SM830276 00_ R32 TD SM indb 38 19 02 28 13 29 52...

Page 316: ...201903 SM830276 00_ R32 TD SM indb 1 19 02 15 8 52 12...