Precision Thick Film Chip Resistors

<±1 %

>

*1 : Use it on the condition that the case temperature is below the upper category temperature.

*2 : Rated continuous working voltage (RCWV) shall be determined from RCWV=

√

Power rating × Resistance value,

or limiting element voltage listed above, whichever less.

*3 : Overload test voltage (OTV) shall be determined from OTV = specified magnification (refer to performance) × RCWV

or maximum overload voltage listed above, whichever less.

*4 : Please contact us when you need a type with a resistance of less than 10 Ω.

Not recommended for new design

Power derating curve

For resistors operated in ambient temperatures

above 70

℃

, power rating shall be derated in

accordance with the figure on the right.

10 to 1 M

10 to 2.2 M

(E24,E96)

Grade 0

Ratings

(E24,E96)

10 to 1 M

±1

(E24,E96)

10 to 2.2 M

±1

100 Ω

≤

R : ±200

200

150

Grade 1

-

Grade 0

±1

(E24,E96)

10 to 1 M

±1

±1

(E24,E96)

10 to 1 M

22-Dec-22

Design and specifications are each subject to change without notice. Ask factory for the current technical specifications before purchase and/or use.

(2512)

(E24,E96)

10 to 1 M

±1

500

200

Should a safety concern arise regarding this product, please be sure to contact us immediately.

1

ERJ1TN

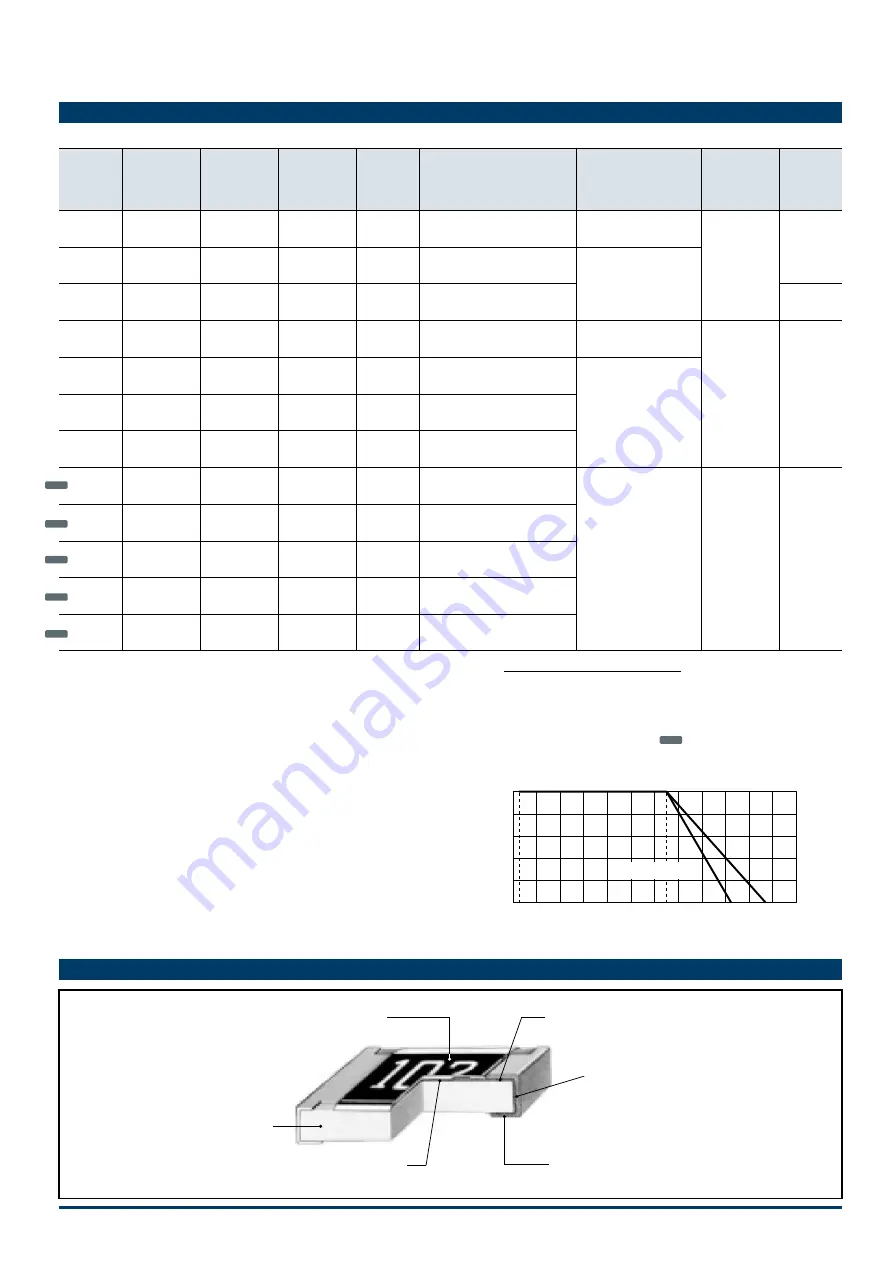

Construction

±100

-55 to

+

155

(E24,E96)

10 to 1 M

500

200

(E24,E96)

AEC-Q200

Grade

Category

temperature

range

(

℃

)

T.C.R.

(×10

-6

/K)

Resistance

range

(Ω)

(E24,E96)

10 to 1 M

*4

R < 100 Ω : ±300

50

25

(E24,E96)

10 to 1 M

*4

±1

30

15

Maximum

overload

voltage

*3

(V)

Limiting

element

voltage

*2

(V)

Resistance

tolerance

(%)

±1

-55 to

+

125

ERJ14N

ERJ2RK

(01005)

(0201)

(0402)

(0402)

100

50

0.1

150

75

0.1

0.1

50

100

0.125

(1206)

(0805)

0.031

ERJ1GN

Part No.

(inch size)

Power rating

*1

(70

℃

)

(W)

ERJXGN

ERJ12N

ERJ12S

(0603)

±1

400

200

0.5

0.25

200

400

±1

ERJ6EN

0.75

200

500

±1

(2010)

(1812)

(1210)

0.75

ERJ8EN

-55 to

+

155

ERJ1GJ

0.05

25

50

±1

(0201)

10 to 1 M

*4

(E24,E96)

±200

ERJ2RC

ERJ3EK

0.05

(E24,E96)

1 to 9.76

–100 to +600

±100

-60

-20

0

20

60

20

40

60

80

100

80 100

140

180

0

-40

40

160

120

-55

℃

70

℃

155

℃

R

at

ed l

oad

(%

)

Ambient temperature (

℃

)

125

℃

ERJXG,1G, 1R

Alumina substrate

Protective coating

Thick film resistive element

Electrode (Outer)

Electrode (Inner)

NRFND

NRFND

NRFND

NRFND

NRFND

NRFND

Electrode (Middle)