Leak Detection Sensor

EX-F70

SERIES

EX-F60

SERIES

860

FIBER

SENSORS

LASER

SENSORS

PHOTO-

ELECTRIC

SENSORS

MICRO

PHOTO-

ELECTRIC

SENSORS

AREA

SENSORS

LIGHT

CURTAINS

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

PARTICULAR

USE

SENSORS

SENSOR

OPTIONS

SIMPLE

WIRE-SAVING

UNITS

WIRE-SAVING

SYSTEMS

MEASURE-

MENT

SENSORS

STATIC

CONTROL

DEVICES

ENDOSCOPE

LASER

MARKERS

PLC /

TERMINALS

HUMAN

MACHINE

INTERFACES

ENERGY

CONSUMPTION

VISUALIZATION

COMPONENTS

FA

COMPONENTS

MACHINE

VISION

SYSTEMS

UV

CURING

SYSTEMS

Selection

Guide

Wafer

Detection

Liquid Leak

Detection

Liquid Level

Detection

Water

Detection

Color Mark

Detection

Hot Melt Glue

Detection

Ultrasonic

Small / Slim

Object Detection

Obstacle

Detection

Other

Products

SQ4

EX-F70/

EX-F60

PRECAUTIONS FOR PROPER USE

Refer to General precautions.

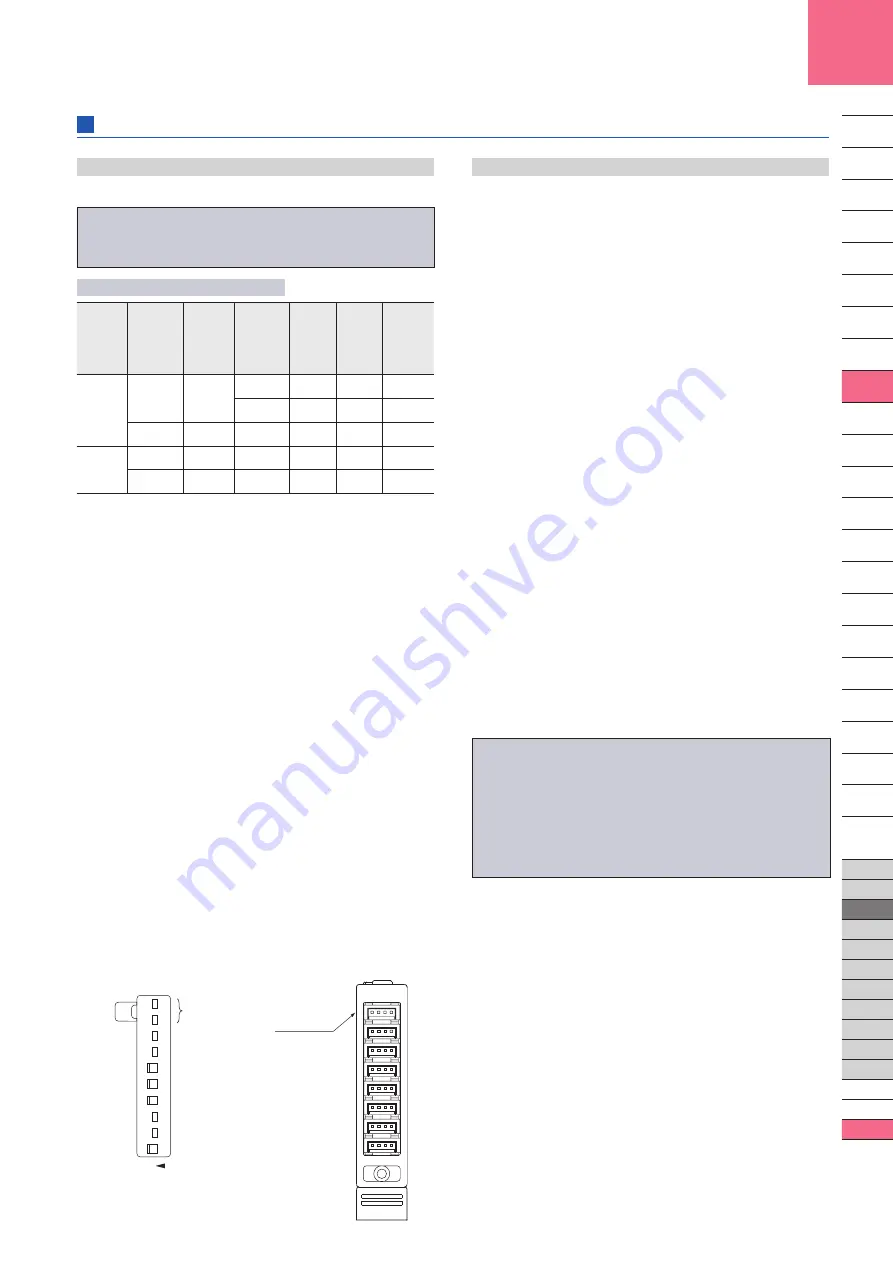

Operation

Connection

state of

the leak

detection

sensor

State of the

connection

setting

switch

Leak

detected

condition

Normal

indicator

(Green)

Error

indicator

(Red)

Output

indicator

(Orange)

Normal

Connected

ON

Not

leaked

Lights

up

Turns

off

Lights

up

Leaked

Turns

off

Lights

up

Turns

off

Unconnected

OFF

―

Turns

off

Turns

off

Lights

up

Error

Connected

OFF

Not

leaked

Lights

up

Lights

up

Turns

off

Unconnected

ON

―

Turns

off

Lights

up

Turns

off

EX-FC1

Connection setting switch

• The connection setting should be carried out in the power

supply off condition after removing any electrostatic charge

which may be present on your body.

• For the channel that the unit sensor is connected to and

the connection setting switch is set to “ON” side, the error

indicator (red) lights up for a moment when the power is

turned on. This is not a malfunction for the unit because it

is caused by characteristic of the sensor.

• Make sure to set the connection setting switch with the

connector No. to which the leak detection sensor is

connected, to “ON” side.

• In case both the normal indicator (green) and the error

indicator (red) light up, the connection setting switch with

the connector No. to which the leak detection sensor is

connected, is not set to “ON” side. Set the connection

setting switch with the connector No. to which the leak

detection sensor is connected, to “ON” side.

• In case the error indicator (red) lights up, the leak

detection sensor detects leak or the connection setting

switch is set to “ON” side without connecting the leak

detection sensor. If the connection setting switch is set to

“ON” side without connecting the leak detection sensor,

set the connection setting switch to “OFF” side.

• If the leak detection sensor detects leak or the connection

setting switch is set to “OFF” side in the state that the

leak detection sensor is improperly mounted to the

mounting bracket, the sensor judges as the output is ON.

Be careful when setting.

All models

Wiring

• Make sure that the power supply is off while wiring.

• Verify that the supply voltage variation is within the rating.

Take care that if a voltage exceeding the rated range or

an AC power supply is directly applied, the sensor may get

damaged or burnt.

• If power is supplied from a commercial switching regulator,

ensure that the frame ground (F.G.) terminal of the power

supply is connected to an actual ground.

• In case noise generating equipment (switching regulator,

inverter motor,etc.) is used in the vicinity of this product,

connect the frame ground (F.G.) terminal of the equipment

to an actual ground.

• Do not run the wires together with high-voltage lines or

power lines or put them in the same raceway. This can

cause malfunction due to induction.

• Make sure to use an isolation transformer for the DC power

supply. If an auto-transformer (single winding transformer)

is used, this product or the power supply may get damaged.

• In case a surge is generated in the used power supply,

connect a surge absorber to the supply and absorb the

surge.

• Cable extension is possible up to total 50 m

164.05 ft

with

0.3 mm

2

, or more, cable (less than 10 m

32.81 ft

for

EX-FC1

). However, in order to reduce noise, make the

wiring as short as possible.

• Make sure that stress by forcible bend or pulling is not

applied directly to the sensor cable joint.

•

EX-FC1

output dose not incorporate a short-circuit

protection circuit.

Do not connect it directly to a power supply or a capacitive

load.

( )

7

6

5

4

3

2

1

0

7

NOT

USED

6

5

4

3

2

1

0

ON

Connector No.

These are not used.

“ON” side

“ON” side

“ON” side

“ON” side

Connection setting switch setting example

In case the input of 0, 3, 4 and 5 are set

to effective.

• In case air bubbles are drawn into the sensing part, take

care that it may take some time for sensing to stabilize, or

sensing may even become unstable.

Check the usage conditions thoroughly before use.

• Do not use during the initial transient time (leak detection

sensor: 50 ms approx.,

EX-FC1

: 0.5 sec. approx.) after

the power supply is switched on.

• Since this sensor employs non-modulated infrared LED,

take sufficient care against extraneous light. Do not

expose the sensing part directly to the extraneous light.

• Avoid dust, dirt, and steam. Further, do not use this

product in an environment containing organic solvents.

• Take care that

EX-7□(-PN)

and

EX-FC1

does not come

in contact with oil, grease or organic solvents, such as,

thinner, etc.

• In case this sensor is used where electrostatic charge

is present, use a metal leak pan, which should be

connected to an actual ground.

• These sensors are only for indoor use.

• Avoid using the product in an explosive atmosphere

because this product does not have an explosive-proof

protective construction.

• When liquid remains on the sensing surface after leak

detection, wipe all liquid from the sensing surface. To

avoid scratching the sensing surface and the enclosed

mounting bracket, use a soft cloth.

Others

Operation matrix for each indicator