1 SCHEMATIC DIAGRAM

2

2 WIRING CONNECTION DIAGRAM

2

3 DISASSEMBLY/ASSEMBLY INSTRUCTIONS

3

©

2003 Matsushita Electric Works Ltd. All rights

reserved. Unauthorized copying and distribution is a

violation of law.

EY6450-U1

4 TROUBLESHOOTING GUIDE

7

5 EXPLODED VIEW

9

6 REPLACEMENT PARTS LIST

10

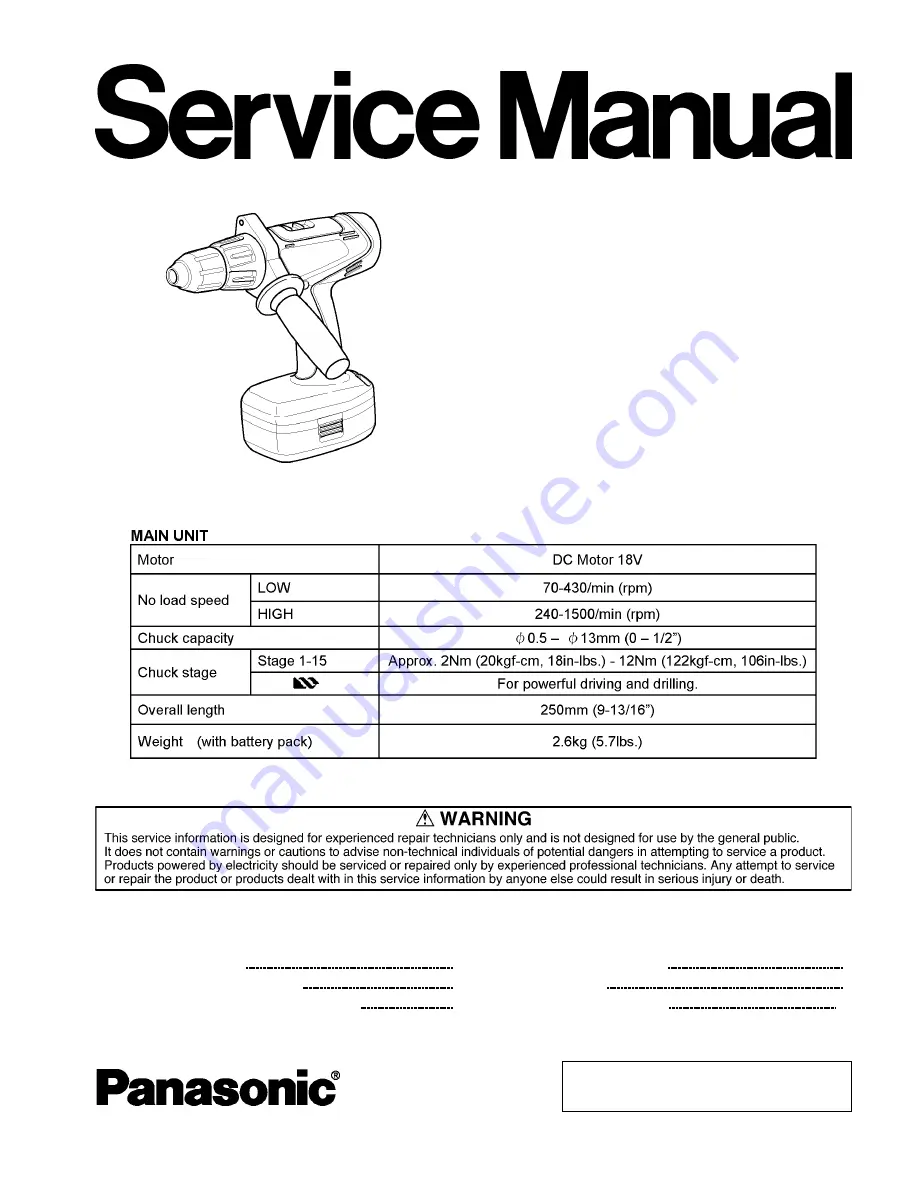

Cordless Drill & Driver

SPECIFICATIONS

CONTENTS

Page

Page

ORDER NO.PTD0308U33C1

F16