■

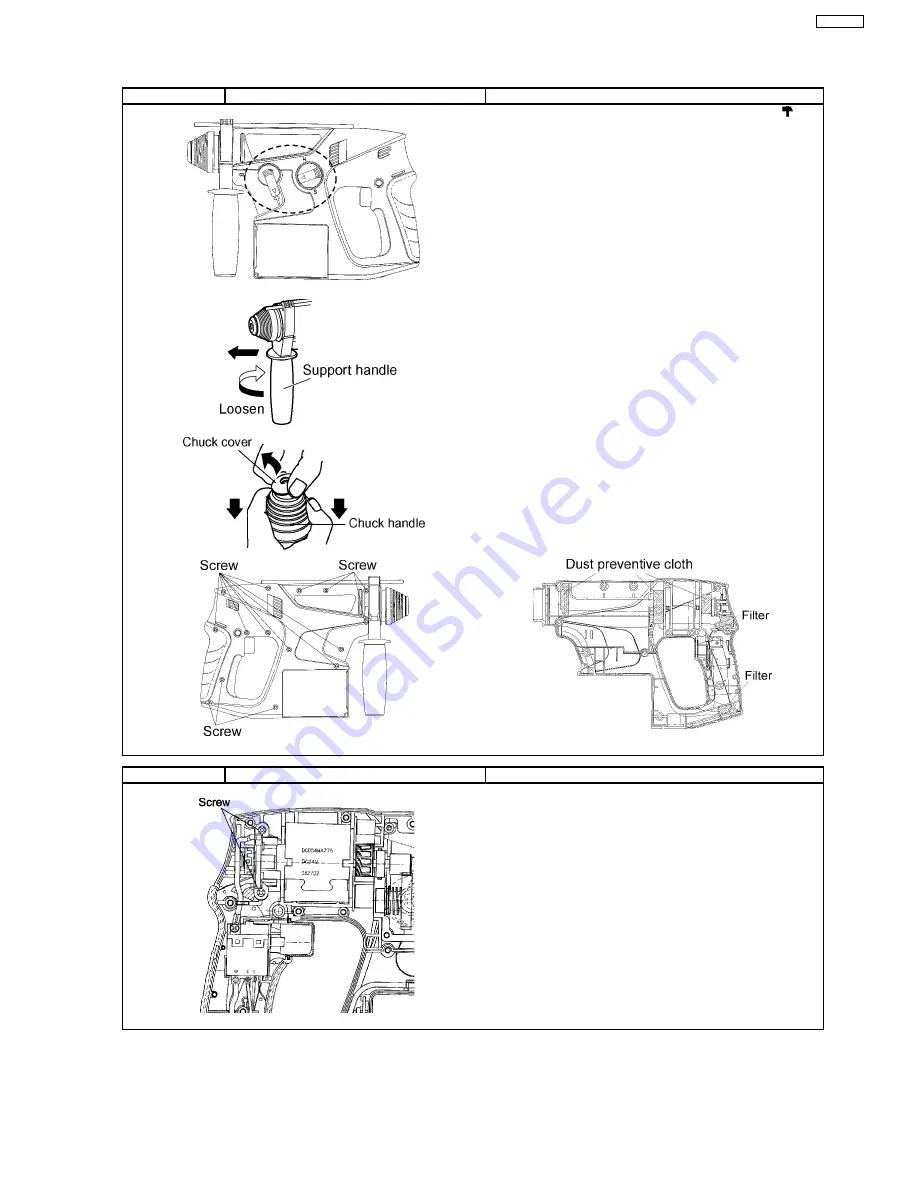

HOW TO DISASSEMBLE THE MAIN UNIT.

3 DISASSEMBLY/ASSEMBLY INSTRUCTIONS

Ref. No. 1A

Procedure 1A

Removal of the housing.

1. Set the hammering/drilling switching lever to the position

and

the speed/blow mode selection lever in between "H" and "S"

position.

2. Loosen the support handle and take it out from the unit.

3. Pluck the chuck cover depressing the chuck handle.

4. Remove 15 housing screws.

For assembling

NOTE :

Make sure to attach the dust preventive clothes or filters on the

housings.

Ref. No. 1B

Procedure 1A

→

→

→

→

1B

Removal of the motor brush assembly.

1. Loosen 2 screws.

3

EY6813-U1