Operation manual for Narrow-pitch connectors F4S

Panasonic Corporation

industrial.panasonic.com/ac/e/

©

Panasonic Corporation 2017

ACCTF5E-5 201704

- 11 -

3) Reinforcing plate design

We recommend the use of a reinforcing plate with appropriate thickness and

rigidity to prevent solder peeling and pattern peeling when unmating the

connector, and to guard against board warpage during the reflow process.

(1)

We recommend the use of a glass-reinforced epoxy resin sheet, since it is

rigid.

(2)

When a polyimide resin plate is used to avoid the generation of fabric

particles:

- Select a thick sheet whenever possible.

(

In general, 0.2 mm or thicker sheet is used.

)

-

High-rigidity epoxy adhesive is recommended for attaching the reinforcing

plate to a flexible board

.

- As a measure to ensure rigidity, attach two thin reinforcing plates using epoxy

adhesive. This achieves greater rigidity than a single reinforcing plate of the

same thickness.

(3)

Warpage of the reinforcing plate during the reflow process or poor soldering

may occur depending on the direction the reinforcing plate on material was

cut. Accordingly, make sure to indicate the direction of the material.

(

Rolled sheets generate warpage depending on material direction, so

therefore, make sure to warpage reduction into consideration.

)

(4)

For using an ultra-thin reinforcing plate for slimming a product, one way is

to use metals such as stainless steel for the reinforcing plate.

(5)

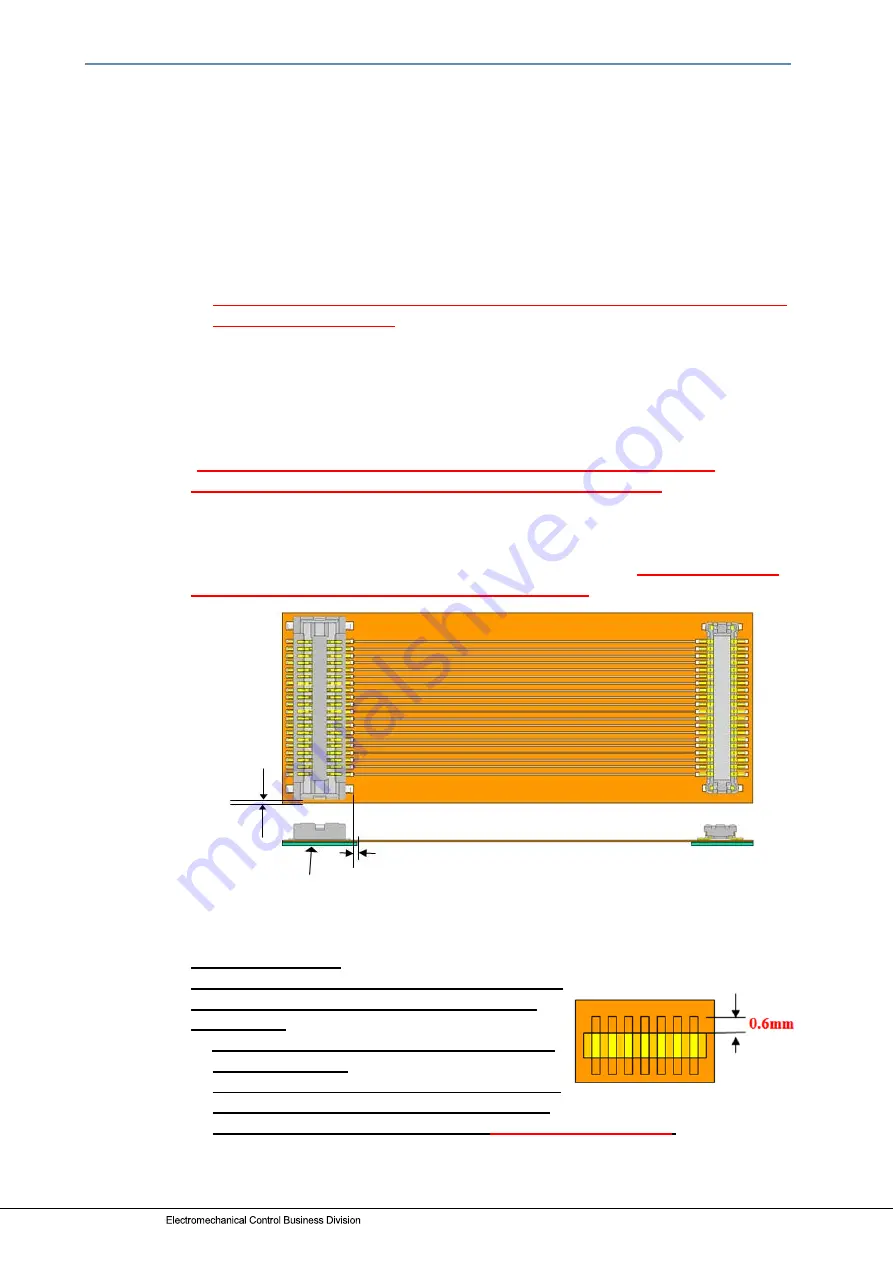

To avoid generating stress on the soldering portion of the connector when

removing the connector or bending an FPC board, design

a reinforcing plate

about 0.5 to 1.0 mm longer from the foot pattern tip

.

(6)

Foot pattern design

The following measure is effective for improving

the strengthening effect when the reinforcing

plate is thin.

-

Make the foot pattern length longer than the

coverlay opening.

In general, it is designed to be about 0.3 mm..

However, when the reinforcing plate is thin,

it is recommended to secure at least

twice the normal length

.

If the connector will

be unmated, set

this to 0.5-1.0 mm.

0.5-1.0 mm

When a thin and soft reinforcing plate is used, the reinforcing

plate may warp if this dimension is too large, which results in

reducing the reinforcing effect.

Reinforcing plate