Operation manual for Narrow-pitch connectors F4S

Panasonic Corporation

industrial.panasonic.com/ac/e/

©

Panasonic Corporation 2017

ACCTF5E-5 201704

- 16 -

■

Picking up the header

(1)The suction area on the header is 0.8 mm in the shorter direction.

If it is difficult to reliably insert the nozzle to the connector bottom face of 0.8

mm widthwise, the header can be picked up by converting the entire top face of

the connector as shown below.

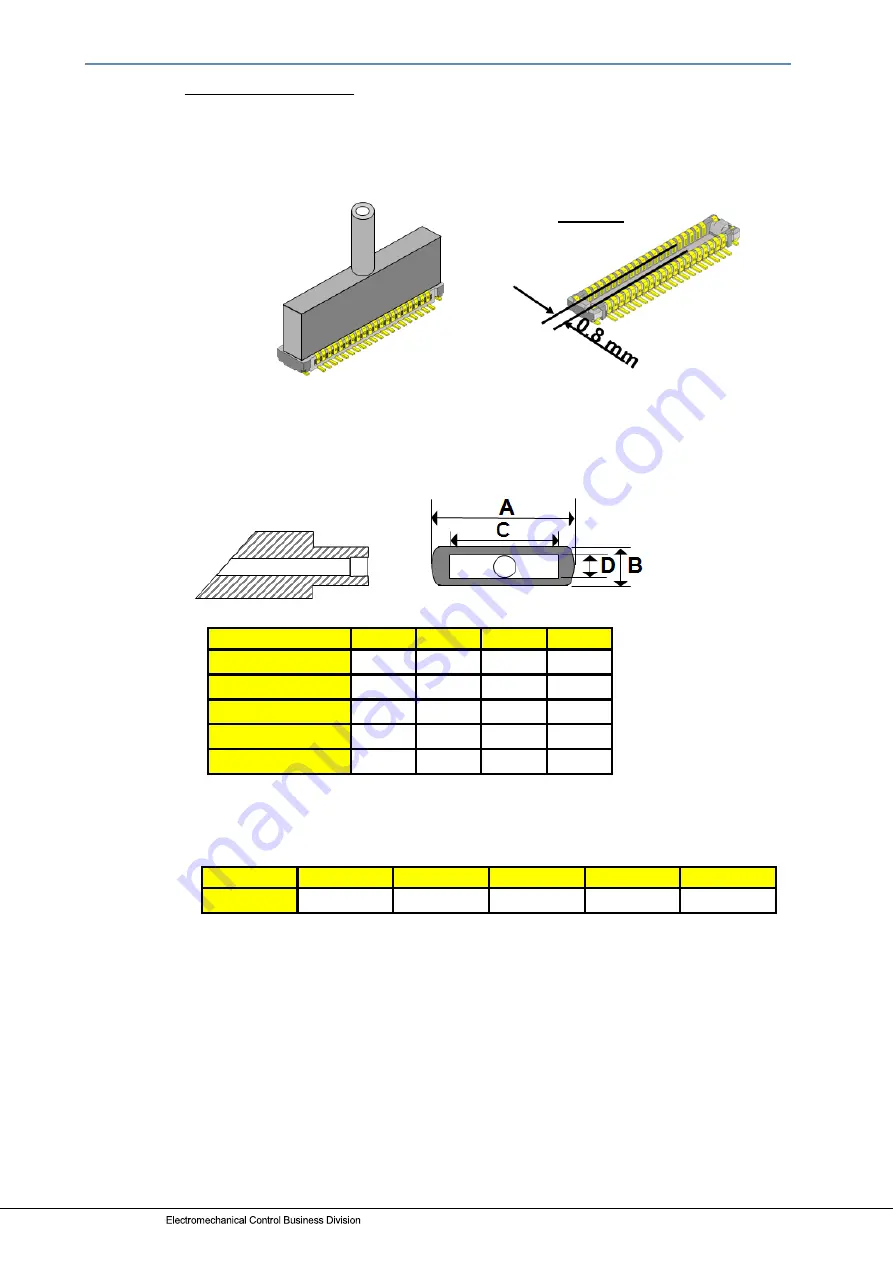

●

Nozzle example (Source: Panasonic Factory Solutions)

Number of contacts

A

B

C

D

10

3.0

1.8

1.0

0.6

20

5.0

1.8

3.0

0.6

30

7.0

1.8

5.0

0.6

40

9.0

1.8

7.0

0.6

50

11.0

1.8

9.0

0.6

●

Single connector weight

10 contacts

20 contacts

30 contacts

40 contacts

50 contacts

Header

0.008

0.013

0.018

0.023

0.027

Header

(Unit

;

g)

(Unit:mm)

Note: The nozzle can be applied to cover the top face of the connector for pickup.