Operation manual for Narrow-pitch connectors F4S

Panasonic Corporation

industrial.panasonic.com/ac/e/

©

Panasonic Corporation 2017

ACCTF5E-5 201704

- 4 -

2) Position of the connector in the mounting process

Design multi-pin connector layouts that do not require a swinging movement

during pickup and mounting.

In many cases, deviation of the connector mounting position is caused by the

inertia of the swinging movement of the mounter. A layout that does not require

swinging is thus required.

●

Example of a connector layout requiring a swinging movement in the mounting process

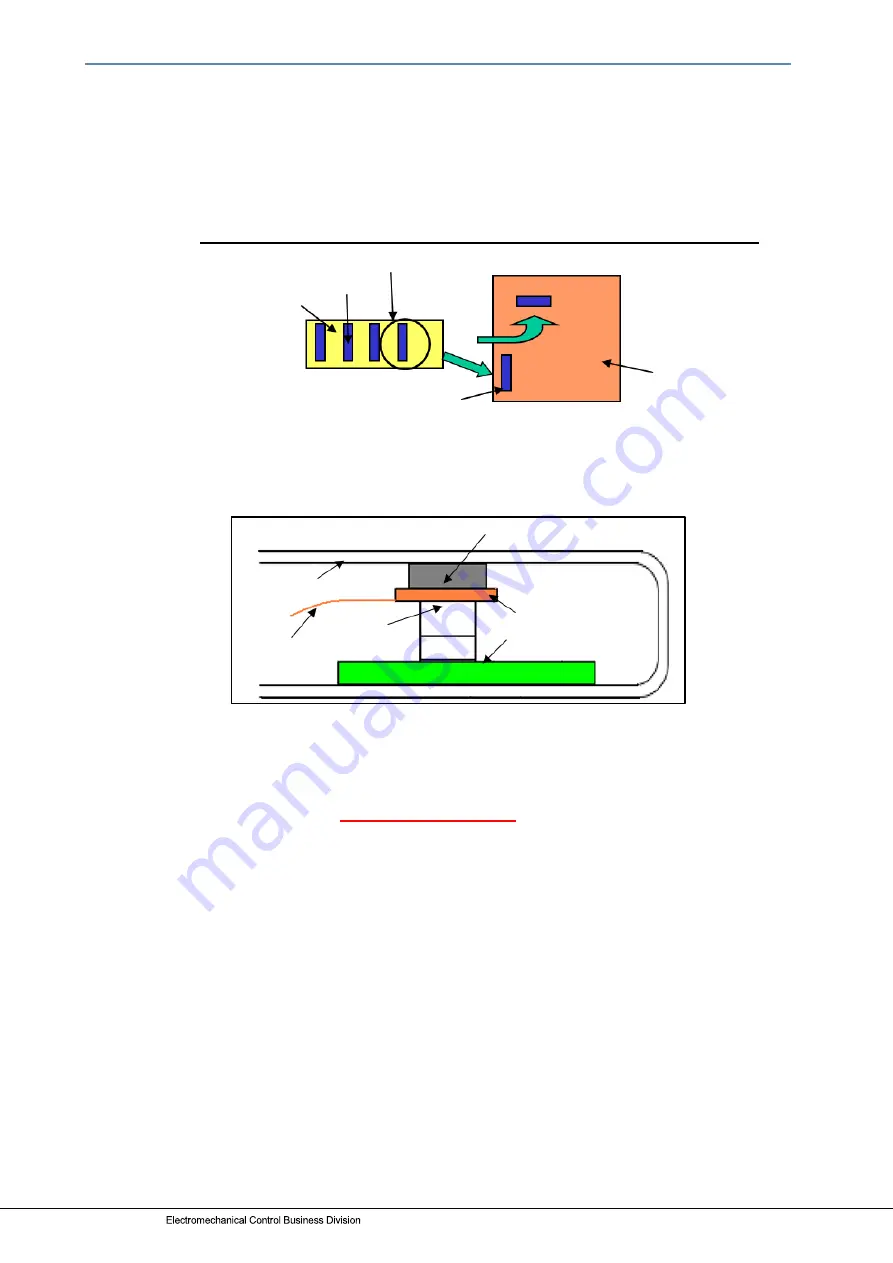

3) Prevention of problems during use

(1)

The F4S connectors have a simple locking structure, but make sure to

consider preventive measures against the detachment of mated connectors

during practical use

.

- Make sure to eliminate any gaps between the casing and board.

- We recommend that the holding force is set greater than the insertion force of

the connector.

- Select an appropriate cushioning material with a suitable shape and dimensions,

and hold down the

connector at the center

. (If the holding position is off the

center, it may cause detachment of mated connectors.)

△

○

Pickup and mounting positions

Connector

Embossed tape

Motherboard

No rotation inertia

Connector

Rotary inertia is applied

Cushioning material

Casing

Sub-board

(flexible board)

Connector

Reinforcing plate

Motherboard