English

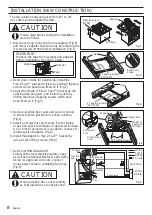

2. Bend down 4 tabs for positioning, install the

Flex-Z Fast bracket to joists by drilling 2 tapping

screws which have been fixed on it. (Fig.2)

TM

TM

3. Adjust the length of Flex-Z Fast bracket as the

spacing between joists, and install to joists by

drilling the other 2 tapping screws which have

been fixed on it. (Fig.3)

4. Remove junction box cover and secure conduit

or stress relief to junction box knock-out hole.

(Fig.4)

TM

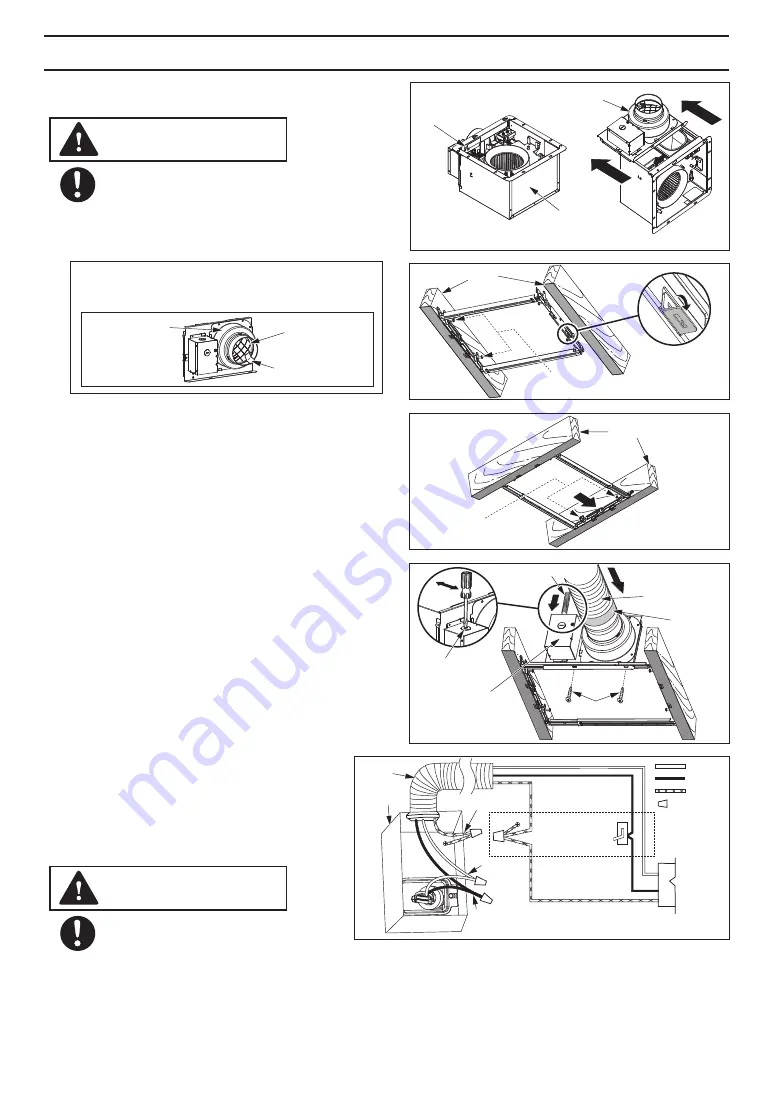

6. Install the adaptor to Flex-Z Fast bracket by

using 2 self-drilling screws. (Fig.4)

5. Install a circular duct and secure it with clamps,

or ties and seal it with mastic or approved foil tape.

A 4 or 6 inch circular duct is needed to connect to

relevant part of adaptor. (Fig.4)

Fig.2

Mount junction box cover carefully

so that lead wires are not pinched.

7. Refer to WIRING DIAGRAM.

Follow all the local electrical safety codes

as well as the National Electrical Code (NEC).

Using UL approved wire nuts, connect

house power wires to ventilating fan wires.

(Fig.5)

2 Tapping screws

(ST4.2X20)

Bend down

4 tabs

Joist

Fig.3

Joist

2 Tapping screws

(ST4.2X20)

2 Self-drilling screws

Knock-out

hole

Junction box

cover

Conduit

Circular duct

Mastic or

approved

foil tape

Fig.4

INSTALLATION (NEW CONSTRUCTION)

Fan body

Adaptor

Fig.1

Machine screw

(M4X8)

The fan position between joists from 16" to 24"

on center can be adjusted flexibly.

Please wear gloves during the installation

work as follow.

CAUTION

machine screw (M4X8) before installation. (Fig.1)

IMPORTANT:

Remove the tape from damper and adaptor

before installation. As shown below:

Tape

Adaptor

Damper

CAUTION

Fig.5

BLACK

WHITE

GREEN

Wire nuts

Junction

box

L

N

120 VAC

LINE IN

Switch box

Conduit

Earth ground

Earth ground

Live

Neutral

8

1. Disconnect plug connector from receptacle (Fig.6)

and remove adaptor from fan body by removing the