2.

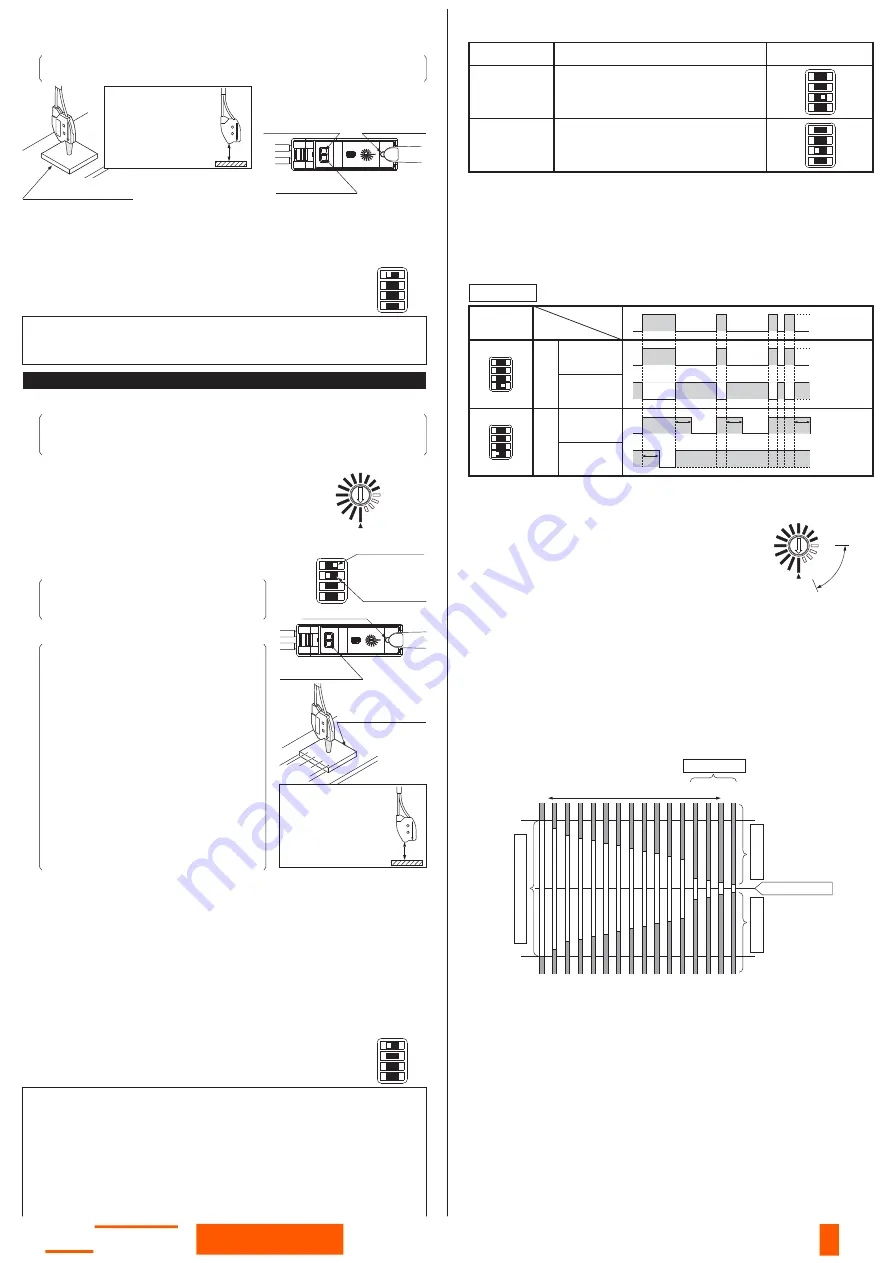

Setting output operation

Either Coincident-ON or Incoincident-ON can be selected.

NORMAL

INVERSE

NORMAL

INVERSE

Output operation

Operation

Coincident-ON

Set the output operation mode switch on 'NORMAL'.

Incoincident-ON

Set the output operation mode switch on 'INVERSE'.

Output operation

mode switch

Ԝ

Set teaching protect switch on 'LOCK'.

*

In case teaching is not properly done.

The operation indicator (red) and the power indicator (green) blink alternately.

Repeat the teaching operation after confirming that the light spot is pro-

jected at right angle to the reference color sample and that the distance

to the sample is appropriate.

SET

LOCK

JAPAN

FZÐ11

NON

OFD

NORMAL

INVERSE

MANUAL

AUTO

SET

LOCK

OUT

POWER

TEACH

TOLERANCE

14

6

10

4

8

12

FINE

Operation indicator

(Red)

Power indicator

(Green)

Teaching button

After the teaching, test the sensing. If the sensor identifies other similar

colors that you do not want to detect, set the tolerance to be finer.

(Refer to '

4. Setting tolerance

' for more details.)

ԛ

Place the sample object, bearing the reference color, under the fiber head at the

setting distance. The surface of the sample object must face the fiber head at

right angle to the beam axis, and the reference color must fill the whole spot area.

Press the teaching button and release it. Then, the sensor recognizes

the reference color as the criterion and starts sensing.

Sample object bearing

the reference color

L

Setting distance L

FD-L51

: 20mm

FD-L52

: 10mm

FD-L53

: 5mm

FD-L54

: 40mm

Sample object bearing

the reference color

SET

LOCK

Ԝ

Run the sample object at the setting distance.

The sensor recognizes the first com-

ing color other than the background

color as the criterion.

The traveling speed must satisfy the

following two conditions.

After the sample object moves away,

the sensor takes 50ms approx. to

complete the teaching. The sensor is

not operable in this period.

The sensor automatically starts sensing af-

ter recognizing the reference color as the

criterion, and the power indicator (green)

stops blinking and lights up continuously.

(1)

(2)

It should be 300 mm/sec. or more.

The reference color must be ex-

posed to the spot for 3ms or more.

Ԙ

Set the tolerance adjuster at the 16th grade

(

ً

mark) with the adjusting screwdriver.

ԙ

Ԛ

Set the teaching protect switch on 'SET'.

Set the setting mode selection switch on

'AUTO'.

Setting by auto-teaching

14

6

10

4

8

12

FINE

MANUAL

AUTO

SET

LOCK

Teaching protect

switch

Setting mode

selection switch

JAPAN

FZÐ11

NON

OFD

NORMAL

INVERSE

MANUAL

AUTO

SET

LOCK

OUT

POWER

TEACH

TOLERANCE

14

6

10

4

8

12

FINE

Power indicator

(Green)

Teaching button

Teaching the reference color on a moving object.

If the sample object includes colors other than the reference color,

perform manual teaching. The sample object must contain only one

uniform color for correct auto-teaching.

ԛ

Press the teaching button and release it.

Then, the sensor enters into the waiting state.

The sensor recognizes the background col-

or, then enters into the waiting state and

the power indicator (green) starts blinking.

ԝ

Set teaching protect switch on 'LOCK'.

*

In case teaching is not properly done.

The power indicator (green) keeps blinking. The sensor still stays in the

waiting state.

Make sure of the perpendicularity of the sample object to the beam axis, the

setting distance between the fiber head and the sample, the time duration

for which the sample passes through the beam, and the consistency of the

background color during the teaching. Then, run the sample object again.

If your reference color is similar to the background color, the teaching

may fail if the tolerance is set at the 16th grade (

ً

mark). Make the tol-

erance of the background color narrower with the tolerance adjuster

from the 1st to the 15th grade according to the contrast between these

colors. Then, run the sample object again.

(Refer to '

4. Setting tolerance

' for more details.)

If you want to change to manual-teaching while the sensor is in the auto-

teaching waiting state, set the setting mode selection switch on 'MANUAL'.

The sensor enters the teaching error state with the operation indicator (red) and

the power indicator (green) blinking alternately. Now, carry out manual-teaching.

To stop teaching during the auto-teaching waiting state, switch off the

power supply once.

If the output operation mode switch and the timer operation mode switch are

operated during the auto-teaching waiting state, although the operation indi-

cator operates, the output does not change till auto-teaching is completed.

Sample object bearing

the reference color

L

Setting distance L

FD-L51

: 20mm

FD-L52

: 10mm

FD-L53

: 5mm

FD-L54

: 40mm

Sample object bearing

the reference color

3.

Setting timer operation

The

FZ-10

series is incorporated with an OFF-delay timer fixed for 40ms

approx. The OFF-delay timer operates when the timer operation mode

switch is set on 'OFD'. Since the output signal is extended by a fixed

time interval, this function is useful when the connected device has a

slow response time or if small objects are being detected, resulting in a

short output signal width.

Time chart

Timer period: T = 40ms approx.

Timer operation

mode switch

Sensing

condition

Operation

Coincident-

ON

Incoincident-

ON

Coincident-

ON

Incoincident-

ON

ON

OFF

ON

OFF

ON

OFF

ON

OFF

NON

OFD

NON

OFD

T

T

T

T

Sensing

Not sensing

Normal

Timer

4.

Setting tolerance

The tolerance adjuster determines the tolerance

of equivalence with respect to the reference color

in 16 grades.

Set the arrow mark of the adjuster to the desired

grade from 1st to 16th using the adjusting screw-

driver.

When the grade is changed, the output is turned ON, once, for resetting.

Even if the grade is changed, the reference color taught earlier does not

change until the sensor is taught again.

When performing auto-teaching, it is possible that teaching may fail de-

pending upon the tolerance grade. If this happens, change the tolerance

grade and repeat the teaching.

For 16th to 5th grade, color identification is done based upon the color

(red, green, blue) component ratio. For 4th to 1st grade (precise range),

brightness is also considered for color identification. Hence, when the

adjuster is set to the FINE side (4th to 1st grade), minute difference in

gloss or color shades are also detected.

٨

Tolerance in precise range (4th to 1st grade)

Within the precise range, color is identified in all aspects of hue, chroma,

and lightness. Hence, the sensor can discriminate the reference color

from others even if there is a subtle difference in glossiness or density.

After the tolerance is set within the precise range, the sensor should be

used under an ambient temperature of +15 to +35

͠

. Also, periodical

teaching should be done to maintain the stable sensing conditions.

Before teaching, wait for a warm-up time of 10min. approx. after switch-

ing on the power supply.

Please take care that extraneous light or vibration may affect the detect-

ability.

14

6

10

4

8

12

FINE

Precise

sensing

range

Precise range

Reference color

ً

FINE

16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

Grade

Tolerance

of

equivalence

Not

identified

Not

identified

Rugghölzli 2

CH - 5453 Busslingen

Tel. +41 (0)56 222 38 18

Fax +41 (0)56 222 10 12

mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SENTRONIC

AG