Design, Specifications are subject to change without notice. Ask factory for technical specifications before purchase and/ or use.

Whenever a doubt about safety arises from this product, please inform us immediately for technical consulation without fail.

Aluminum Electrolytic Capacitor

–

EE21

–

(3) A thorough drying after cleaning is required to

remove residual cleaning solvents which may be

trapped b e t w e e n the capacitor and the circuit

board. Avoid drying temperatures which exceed

the maximum rated temperature of the capacitor.

(4) Monitor the contamination levels of the cleaning

solvents during use by electrical conductivity, pH,

specific gravity, or water content. Chlorine levels

can rise with contamination and adversely affect

the performance of the capacitor.

✽

Please consult us for additonal information about

acceptable cleaning solvents or cleaning methods.

2.9 Mounting Adhesives and Coating Agents

When using mounting adhesives or coating agents to

control humidity, avoid using materials containing

h a l o g e n a t e d s o l v e n t s . A l s o , a v o i d t h e u s e o f

chloroprene based polymers.

✽

After applying adhesives or coatings, dry thoroughly

to prevent residual solvents from being trapped

between the capacitor and the circuit board.

3. Precautions for using capacitors

3.1 Environmental Conditions

C a p a c i t o r s s h o u l d not b e u s e d i n t h e f o l l o w i n g

environments.

(1) Temperature exposure above the maximum rated

or below the minimum rated temperature of the

capacitor.

(2) Direct contact with water, salt water, or oil.

(3) H i g h h u m i d i t y c o n d i t i o n s w h e r e w a t e r c o u l d

condense on the capacitor.

(4) Exposure to toxic gases such as hydrogen sulfide,

sulfuric acid, nitric acid, chlorine, or ammonia.

(5) Exposure to ozone, radiation, or ultraviolet rays.

(6) V i b r a t i o n a n d s h o c k c o n d i t i o n s e x c e e d i n g

specified requirements.

4. Emergency Procedures

(1) I f t h e p r e s s u r e r e l i e f v e n t o f t h e c a p a c i t o r

operates, immediately turn off the equipment and

disconnect from the power source. This will

m i n i m i z e a d d i t i o n a l d a m a g e c a u s e d b y t h e

vaporizing electrolyte.

(2) Avoid contact with the escaping electrolyte gas

which can exceed 100

°

C temperatures.

If electrolyte or gas enters the eye, immediately

flush the eye with large amounts of water.

If electrolyte or gas is ingested by mouth, gargle

with water. If electrolyte contacts the skin, wash

with soap and water.

5. Long Term Storage

Leakage current of a capacitor increases with long

storage times. The aluminium oxide film deteriorates

as a function of temperature and time. If used

without reconditioning, an abnormally high current

will be required to restore the oxide film. This current

surge could cause the circuit or the capacitor to fail.

Capacitor should be reconditioned by applying rated

voltage in series with a 1000

Ω

, current limiting

resistor for a time period of 30 minutes.

5.1 Environmental Conditions (Storage)

Capacitors should not be stored in the following

environments.

(1) Temperature exposure above 35°C or below 15

°

C.

(2) Direct contact with water, salt water, or oil.

(3) High humidity conditions where water could

condense on the capacitor.

(4) E x p o s u r e t o t o x i c g a s e s s u c h a s h y d r o g e n

sulfide,sulfuric acid, nitric acid, chlorine, or

ammonia.

(5) Exposure to ozone, radiation, or ultraviolet rays.

(6) V i b r a t i o n a n d s h o c k c o n d i t i o n s e x c e e d i n g

specified requirements.

3.2 Electrical Precautions

(1) Avoid touching the terminals of the capacitor as

possible electric shock could result. The exposed

aluminium case is not insulated and could also

cause electric shock if touched.

( 2 ) A v o i d s h o r t c i r c u i t i n g t h e a r e a b e t w e e n t h e

capacitor terminals with conductive materials

including liquids such as acids or alkaline solutions.

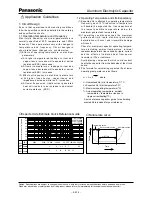

Type

Surface mount type

Lead type

Snap-in type

Series

V(

Except EB

Series

)

Bi-polar SU

M

KA

Bi-polar KA

FB

FC

GA

NHG

EB

TA

TS UP

TS HA

Cleaning permitted

L

L

L

(~ 100V)

L

L

L

L

L

L(

~ 100V)

L(

~ 100V)

L

L(

~ 100V)

L(

~ 100V)