Summary of Contents for HM-TA20EB

Page 8: ...8 4 Specifications ...

Page 9: ...9 ...

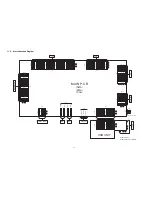

Page 12: ...12 6 Troubleshooting Guide 6 1 Confirmation Flow of Waterproof ...

Page 13: ...13 6 2 Airtight Inspection with Air Leak Tester ...

Page 14: ...14 6 3 Air Leak Tester RFKZ0528 Operating Instruction ...

Page 15: ...15 ...

Page 16: ...16 ...

Page 17: ...17 ...

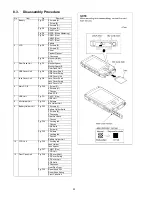

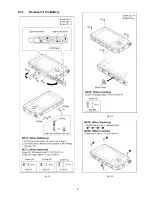

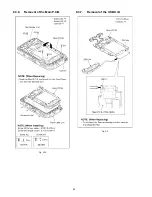

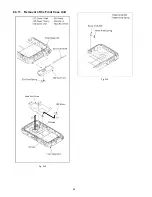

Page 21: ...21 8 3 1 Removal of the Battery Fig D1 Fig D2 Fig D3 ...

Page 22: ...22 Fig D4 8 3 2 Removal of the LCD Fig D5 ...

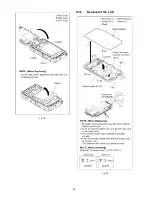

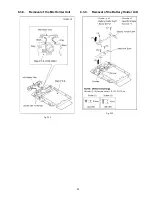

Page 24: ...24 8 3 6 Removal of the Main P C B Fig D10 8 3 7 Removal of the USB Unit Fig D11 ...

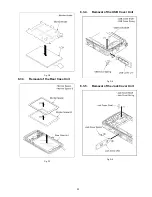

Page 26: ...26 Fig D14 Fig D15 ...

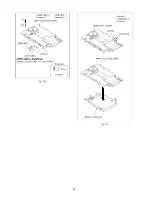

Page 27: ...27 8 3 10 Removal of the CCD Unit Fig D16 Fig D17 ...

Page 28: ...28 8 3 11 Removal of the Front Case Unit Fig D18 Fig D19 ...

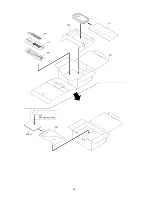

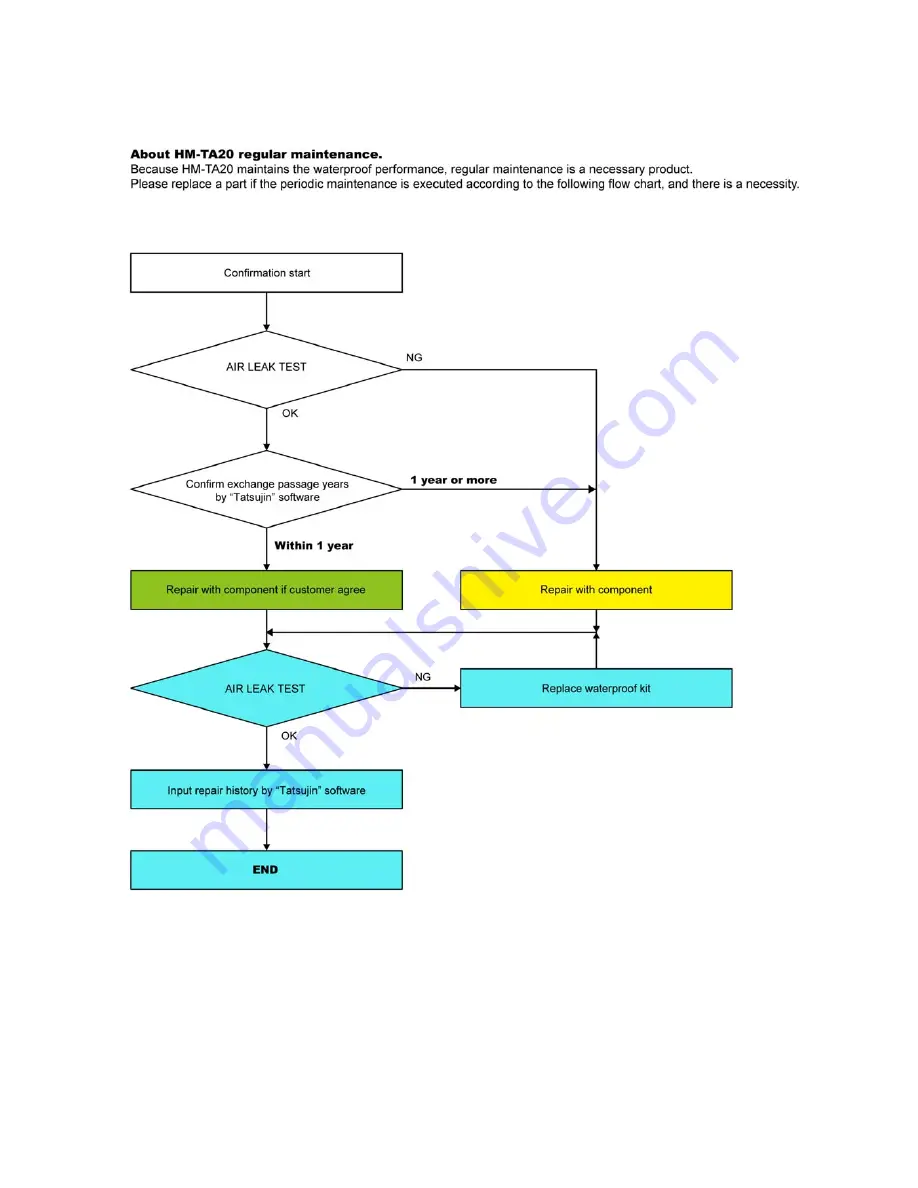

Page 31: ...31 10 Maintenance 10 1 Regular Maintenance Flow ...

Page 32: ...32 10 2 Component Kits of Waterproof ...

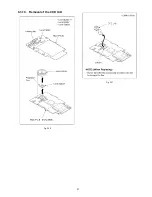

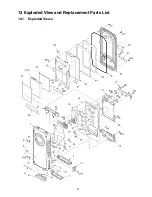

Page 35: ...35 12 Exploded View and Replacement Parts List 12 1 Exploded Views ...

Page 36: ...36 ...