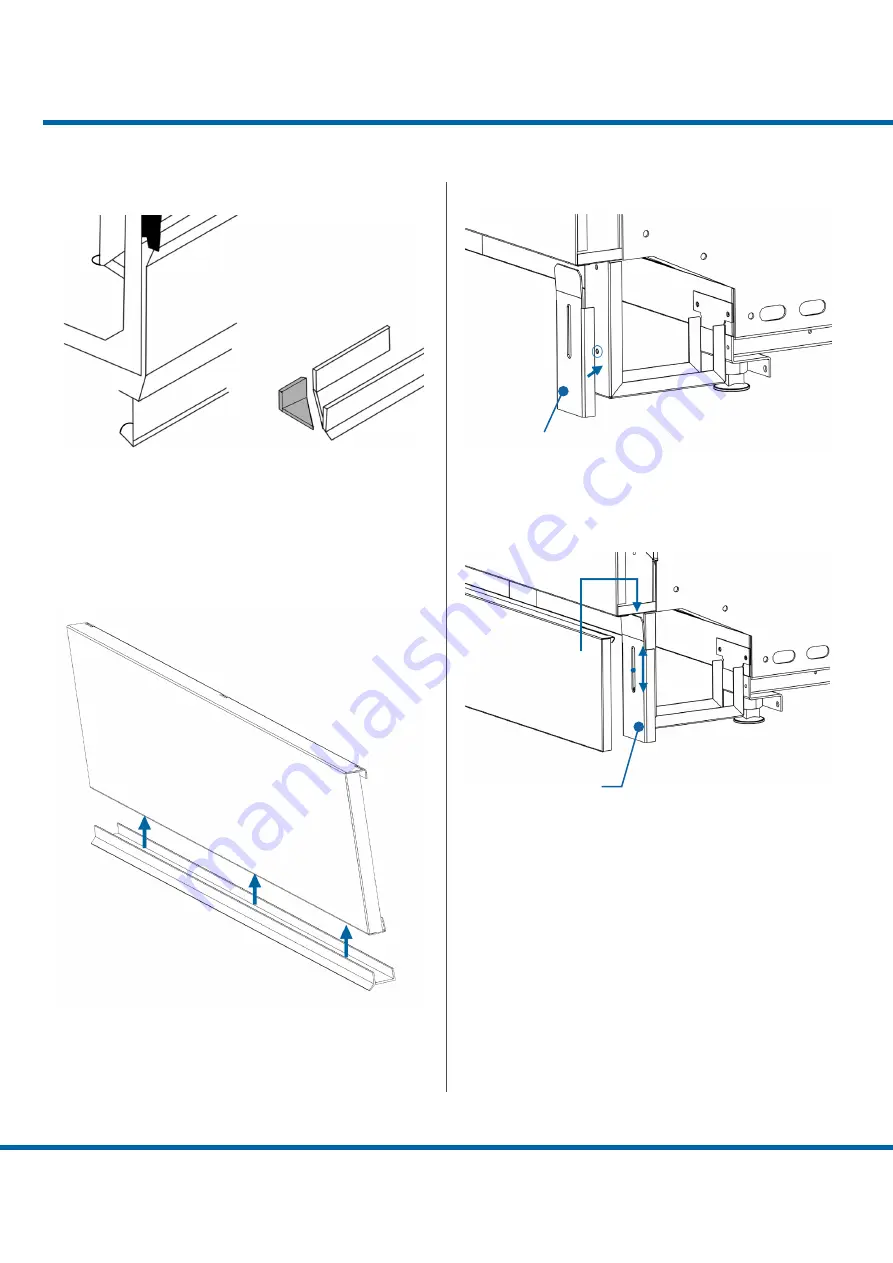

Kick plate Support

Kick Plate Support

PAGE 23

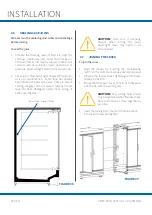

SMED SEMI VERTICAL - HUSSMANN

This front kickplate ajdustment bracket will be screwed

onto the support assembly.

Attach the front kickplate panel to the kickplate support

bracket by hooking the slot onto top of the bracket. This

will allow the kickplate to slide vertically to allow for a

slight variation in height.

On patch or crown end kickplates, cut the profile seal

in a 45

0

angle in order to attach it to the bottom of the

front kickplate panel.

Attach the profile seal to the bottom of the front

kickplate panel.

3.8

ATTACHING KICK PLATES

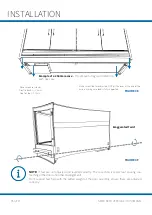

FIGURE 3W

FIGURE 3X

FIGURE 3Y

FIGURE 3Z

INSTALLATION