NOTE:

The U.S. Government standard is 5 mW/cm

2

while in the

customer’s home. 2mW/cm

2

stated here is our own

voluntary standard. (1mW/cm

2

for Canada)

7.1. Equipment

•

•

•

•

Electromagnatic radiation monitor

•

•

•

•

Glass thermometer 212°F or 100°C

•

•

•

•

600cc glass beaker

7.2. Procedure for measuring

radiation leakage

Note before measuring.

•

•

•

•

Do not exceed meter full scale deflection. Leakage monitor

should initially be set to the highest scale.

•

•

•

•

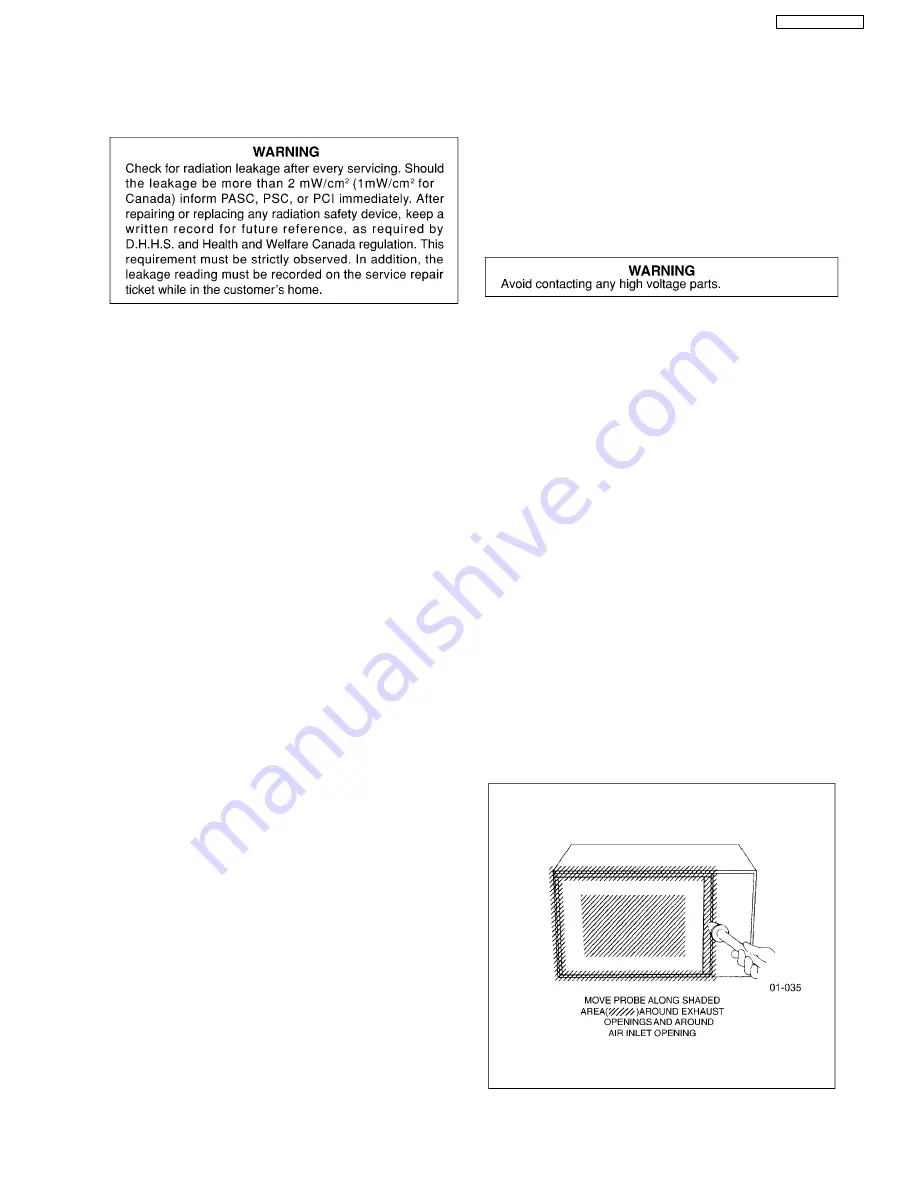

To prevent false readings the test probe should be held by

the grip portion of the handle only and moved along the

shaded

area

in

Figure

no

faster

than

1

inch/sec

(2.5cm/sec).

•

•

•

•

Leakage with the outer panel removed ...... less than

5mW/cm

2

.

•

•

•

•

Leakage for a fully assembled oven with door normally

closed ...... less than 2mW/cm

2

(1mW/cm

2

for Canada).

•

•

•

•

Leakage for a fully assembled oven [Before the latch switch

(primary) is interrupted] while pulling the door ...... less than

2mW/cm

2

.

1. Pour 275 ± 15cc (9ozs

s

± 1/2oz) of 20°C ± 5°C (68° ± 9°F)

water in a beaker which is graduated to 600cc, and place in

the center of the oven.

2. Set the radiation monitor to 2450MHz and use it following

the manufacturer´s recommended test procedure to assure

correct results.

3. When measuring the leakage, always use the 2 inch (5cm)

spacer supplied with the probe.

4. Tap the start pad or set the timer and with the magnetron

oscillating, measure the leakage by holding the probe

perpendicular to the surface being measured.

7.2.1. Measurement with the outer panel

removed.

Whenever you replace the magnetron, measure for radiation

leakage before the outer panel is installed and after all

necessary components are replaced or adjusted. Special care

should be taken in measuring around the magnetron.

7.2.2. Measurements with a fully

assembled oven.

After all components, including outer panel are fully assembled,

measure for radiation leakage around the door periphery, the

door viewing window, the exhaust opening and air inlet

openings.

7.3. Record keeping and

notification after measurement

•

•

•

•

After any adjustment or repair to a microwave oven, a

leakage reading must be taken. Record this leakage

reading on the repair ticket even if it is zero.

A copy of this repair ticket and the microwave leakage

reading should be kept by repair facility.

•

•

•

•

Should the radiation leakage be more than 2 mW/cm

2

(1mW/cm for Canada) after determining that all parts are in

good

condition,

functioning

properly,

and

genuine

replacement parts as listed in this manual have been used,

immediately notify PASC, PSC or PCI.

7.4. At least once a year, have the

radiation monitor checked for

calibration by its

manufacturer.

7 PROCEDURE FOR MEASURING MICROWAVE ENERGY

LEAKAGE

19

NN-T695 NN-T685SF

Summary of Contents for INVERTER NN-H665

Page 2: ...2 NN T695 NN T685SF ...

Page 3: ...3 NN T695 NN T685SF ...

Page 5: ...1 SCHEMATIC DIAGRAM 1 1 APH 5 NN T695 NN T685SF ...

Page 6: ...1 2 CPH 6 NN T695 NN T685SF ...

Page 7: ...1 3 RPH 7 NN T695 NN T685SF ...

Page 24: ...9 EXPLODED VIEW AND PARTS LIST 9 1 EXPLODED VIEW 24 NN T695 NN T685SF ...

Page 35: ...10 DIGITAL PROGRAMMER CIRCUIT 10 1 NN T695SF APH CPH T695SF SM RPH 35 NN T695 NN T685SF ...

Page 36: ...36 NN T695 NN T685SF ...

Page 37: ...10 2 NN T685SF APH CPH T675SF APH 37 NN T695 NN T685SF ...

Page 38: ...38 NN T695 NN T685SF ...

Page 39: ...10 3 NN T665SF APH T655SF APH T664SFR APH 39 NN T695 NN T685SF ...

Page 40: ...40 NN T695 NN T685SF ...

Page 41: ...10 4 NN H665 APH CPH H635 APH S655 APH S645 APH S615 CPH 41 NN T695 NN T685SF ...

Page 42: ...42 NN T695 NN T685SF ...

Page 44: ...44 NN T695 NN T685SF ...