2.1. Variable power cooking

control

High Voltage Inverter Power Supply (U) controls output power

by the signal from Digital Programmer Circuit (DPC). Power

relay always stay on, but PWM (Pulse Width Modulation) signal

controls microwave output power.

NOTE:

The ON/OFF time ratio does not correspond with the

percentage of microwave power since approximately 2

seconds are required for heating of magnetron

filament.

Variable Power Cooking

POWER SETTING

OUTPUT

POWER(%)

APPROX.

MANUAL MICROWAVE

DUTY

ON(SEC)

OFF(SEC)

HIGH

P10

100%

22

0

P9

90%

22

0

P8

80%

22

0

MEDIUM-HIGH

P7

70%

22

0

MEDIUM

P6

60%

22

0

P5

50%

22

0

P4

40%

22

0

MEDIUM-LOW

P3

30%

22

0

P2

20%

15

7

P1

10%

8

14

2.2. Inverter power supply circuit

The Inverter Power Supply circuit powered from the line

voltage, 120V 60Hz AC input supplies 4,000V DC to the

magnetron tube, and functions in place of the H.V. transformer,

the H.V. capacitor and H.V. diode.

1. The AC input voltage 120V 60Hz is rectified to DC voltage

immediately.

2. DC voltage will be supplied to the switching devices called

IGBT. These devices are switched ON-OFF by the 20 to 40

kHz PWM (pulse width modulation) signal from the

microcomputer in the DPC.

3. This drives the High voltage transformer to increase voltage

up to 2,000V AC.

4. Then the half-wave doubler voltage rectifier circuit,

consisting of the H.V. diodes and capacitors, generates the

necessary 4,000V DC needed for the magnetron.

5. Output power of the magnetron tube is always monitored by

the signal output from the current transformer built into the

inverter circuit.

6. This signal is fed back to the microcomputer in the DPC to

determine operating conditions and output necessary to

control PWM signal to the Inverter Power Supply for control

of the output power.

2.3. Inverter defrost

When the Auto Control feature is selected and the Start pad is

tapped:

1. The digital programer circuit determines the power level and

cooking time to complete cooking and indicates the

operating state in the display window. Table shows the

corresponding cooking times for respective serving by

categories.

Inverter Turbo Defrost

SELECTED WEIGHT

COOKING TIME

1.0 LB

4 min.00 sec.

2. When cooking time in the display window has elapsed, the

oven turns off automatically by a control signal from the

digital programmer circuit.

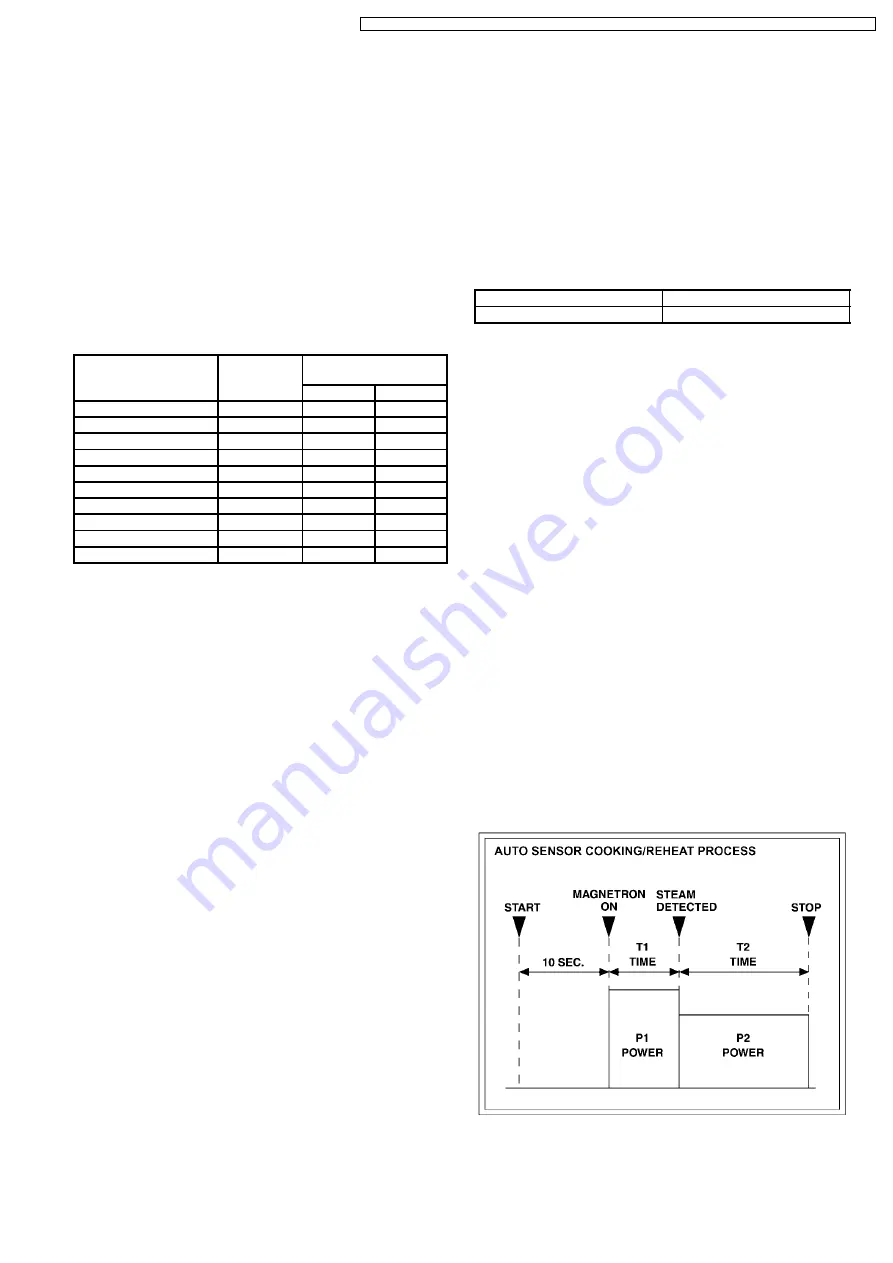

2.4. Sensor cooking (Only for

sensor models)

Auto sensor cooking without setting a power level or selecting

a time. All that is necessary is to select an Auto Sensor

Program before starting to cook.

Understanding Auto Sensor Cooking

As the food cooks, a certain amount of steam is produced.

If the food is covered, this steam builds up and eventually

escapes from the container. In Auto Sensor Cooking, a

carefully designed instrument, called the steam sensor

element, senses this escape of steam. Then, based upon

the Auto Sensor Program selected, the unit will

automatically determine the correct power level and the

proper length of time it will take to cook the food.

NOTE:

Auto Sensor Cooking is successful with the foods and

recipes found in the Auto Sensor Cooking Guide.

Because of the vast differences in food composition,

items not mentioned in the Cooking Guide should be

prepared in the microwave oven using power select

and time features. Please consult Variable Power

Microwave Cookbook for procedures.

2 DESCRIPTION OF OPERATING SEQUENCE

7

NN-SD691S / NN-ST681S / NN-SD671S / NN-ST671S / NN-ST661S / NN-ST661B / NN-ST661W / NN-ST651B / NN-ST651W

Summary of Contents for Inverter NN-ST651W

Page 2: ...2 NN SD691S NN ST681S NN SD671S NN ST671S NN ST661S NN ST661B NN ST661W NN ST651B NN ST651W ...

Page 3: ...3 NN SD691S NN ST681S NN SD671S NN ST671S NN ST661S NN ST661B NN ST661W NN ST651B NN ST651W ...

Page 38: ...38 NN SD691S NN ST681S NN SD671S NN ST671S NN ST661S NN ST661B NN ST661W NN ST651B NN ST651W ...

Page 40: ...40 NN SD691S NN ST681S NN SD671S NN ST671S NN ST661S NN ST661B NN ST661W NN ST651B NN ST651W ...