36

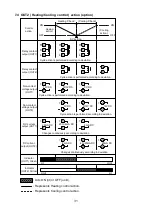

(B) In the case of a stable control

The AT process will fluctuate around the SV.

(1) Calculating PID constant

(2) PID constant calculated

(3) Controlled by the PID

constant set by auto-tuning

(Fig. 8.2-2)

(C) In the case of a large difference between the SV and processing temperature as

the temperature is falling

When AT bias is set to 20 , the

AT process will fluctuate

at the temperature 20

higher than the SV.

(1) Calculating PID constant

(2) PID constant calculated

(3) Controlled by the PID

constant set by auto-tuning

(4) AT bias value

(Fig. 8.2.3)

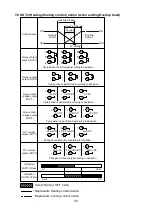

8.3 Auto-reset (offset correction)

Auto-reset is performed to correct the offset at the point at which PV indication

is stabilized within the proportional band during the PD action.

Since the corrected value is internally memorized, it is not necessary to perform

the auto-reset again as long as the process is the same.

However, when the proportional band is set to 0, the corrected value is cleared.

(Fig. 8.3-1)

Temperature

SV

Offset span

Time

Offset is corrected

Auto-reset is performed

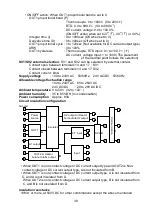

AT starting point

(1)

(2)

(3)

Temperature

SV

Time

AT starting point

(1)

(2)

(3)

(4)

Temperature

SV

Time

Temperature 20

higher than the SV