65

9.3.

Operation

This section describes each operation (or status indication), according to the function item list shown in Sec. 9.2.

9.3.1.

Scanner Status

This function indicates the scanner status, updating it every few seconds.

The status messages and their contents are as follows.

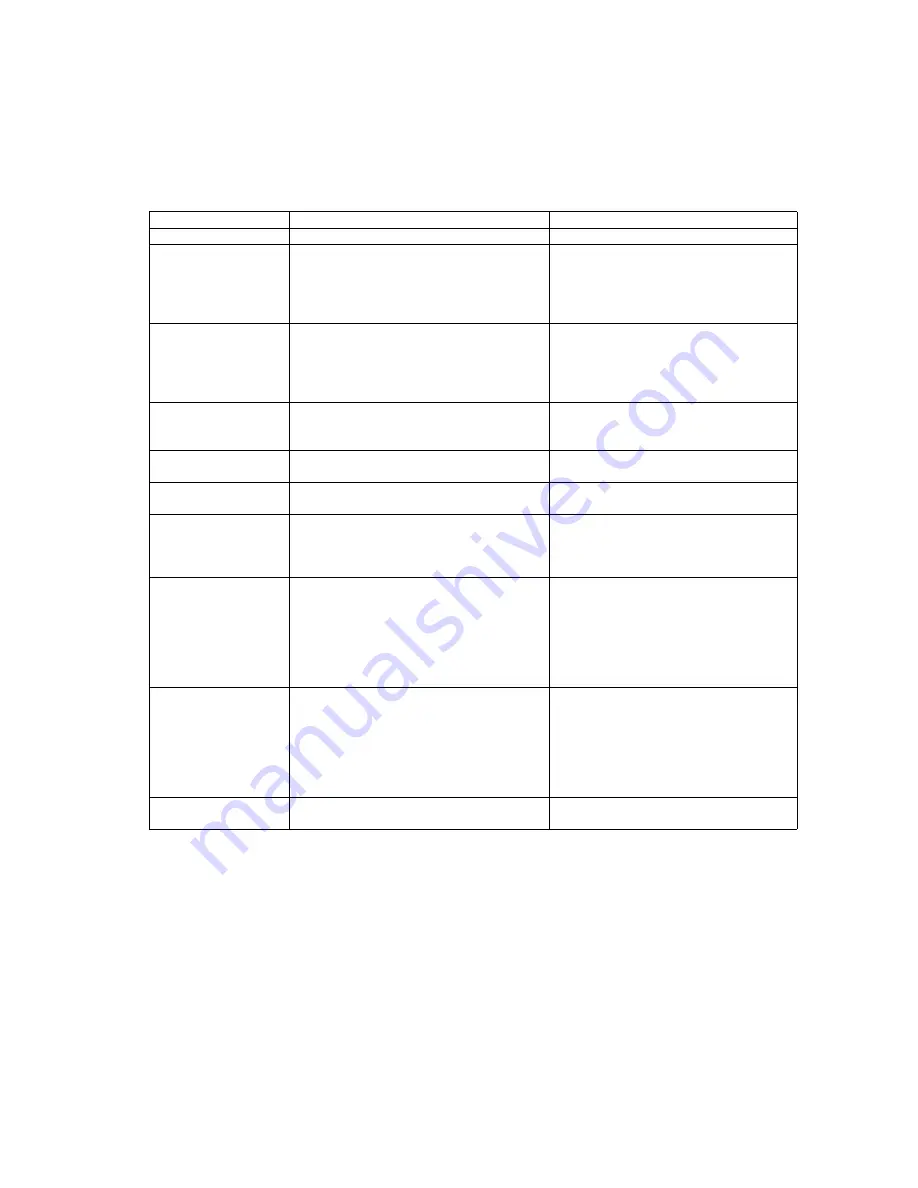

Fig. 9.3.1 Scanner Status

Classified Code

Status Message

Contents

—

Scanner has no error.

No error

U11/ U16/ U23

A paper jam or double feed has occurred.

Open the scanner’s door, remove the

documents, and close the door.

Place the documents back in the document

feed tray.

Paper jam or double feed error

U18

Paper remains in the scanner.

Open the scanner’s door, remove the

documents, and close the door.

Place the documents back in the document

feed tray.

Document remains in the scanner, there is

dust around a sensor, or the sensor

arm does not work properly.

U30

Scanner Door is open!

Please close the door.

ADF Door is open, or does not close tightly.

Or the door detection mechanism does not

work properly.

Fxx

System error occurred!

Please consult with a service representative.

This type of error code requires a

Service-person's attention.

—

No Paper!

Please set the paper.

No paper error

—

The rollers need to be cleaned.

Please clean the rollers.

Please select “Clear Counter” button after

cleaning the rollers.

Warning for cleaning the rollers

—

The Double-feed Prevention Roller

(consumable) is reaching the end of their

usable life. To insure reliable operation,

please replace this roller with Roller

Exchange Kit for your specific scanner.

After replacing the roller, select the “Clear

Counter” button.

Warning for replacing the Double-feed

Prevention Roller

—

The Paper Feed Roller (consumable) is

reaching the end of their usable life.

To insure reliable operation, please replace

this roller with Roller Exchange Kit for your

specific scanner.

After replacing the roller, select the “Clear

Counter” button.

Warning for replacing the Paper Feed

Roller

—

Scanner is not connected!

Scanner is not connected to the PC

properly.

Summary of Contents for KV-S1020C SERIES

Page 10: ...10 ...

Page 28: ...28 ...

Page 41: ...41 8 Remove the screw c and the screw d And pull out the Conveyor Motor ...

Page 62: ...62 ...

Page 78: ...78 Fig 10 1 1 Fig 10 1 2 Fig 10 1 3 Fig 10 1 4 Fig 10 1 5 Fig 10 1 6 ...

Page 79: ...79 Fig 10 1 7 Fig 10 1 8 ...

Page 85: ...85 Fig 10 2 5 Fig 10 2 6 Fig 10 2 7 Fig 10 2 8 Fig 10 2 9 ...

Page 86: ...86 ...

Page 89: ...89 11 3 Block Diagram 3 ...

Page 95: ...95 5 2 CONTROL Board KV S1025C Series KV S1020C Series ...

Page 96: ...96 5 3 CONTROL Board KV S1025C Series KV S1020C Series ...

Page 97: ...97 5 4 CONTROL Board KV S1025C Series KV S1020C Series ...

Page 102: ...102 ...

Page 104: ...104 13 1 CONTROL Board 13 1 1 Front Side PbF stamp ...

Page 105: ...105 13 1 2 Back Side ...

Page 109: ...109 14 Parts Location and Mechanical Parts List ...

Page 110: ...110 14 1 Exterior and Chassis ...