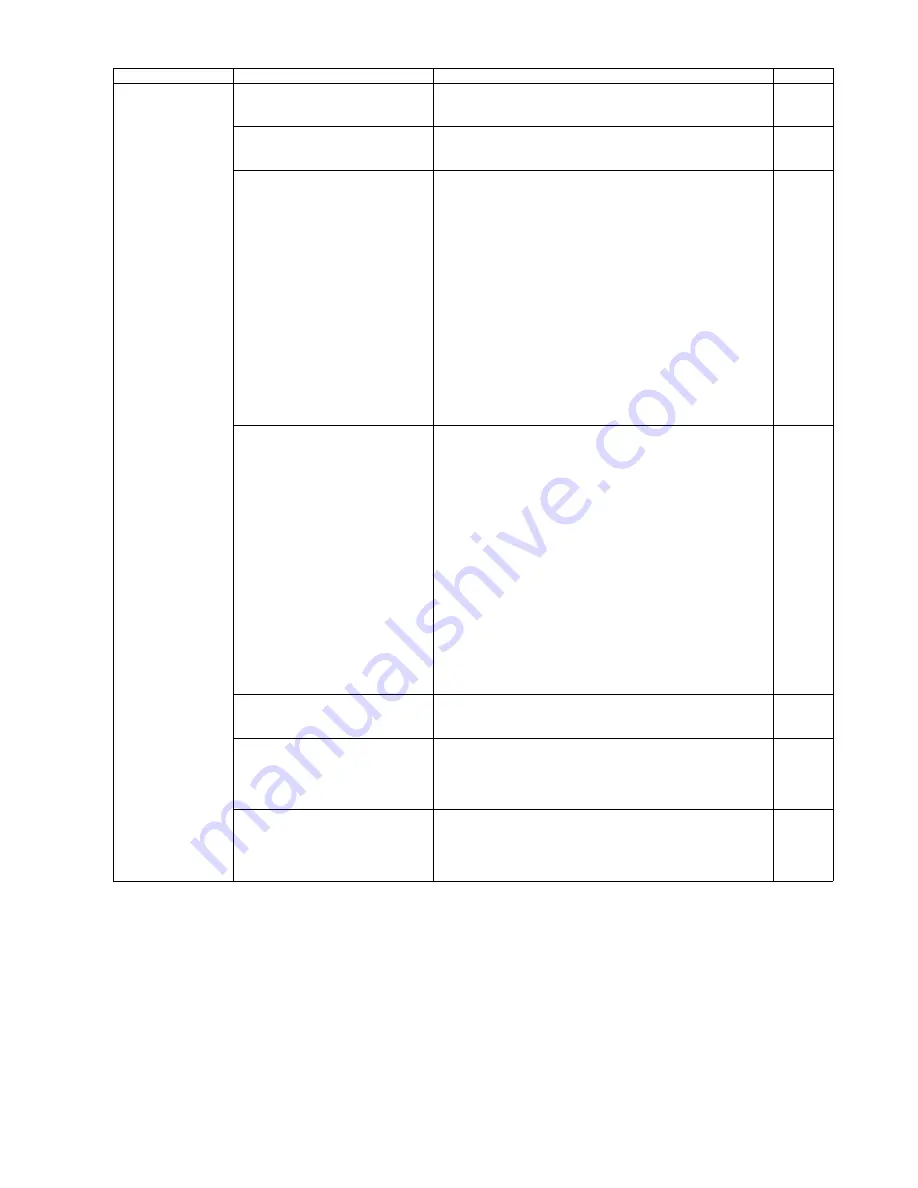

77

Scanned image data

have black line, white

line, darker image than

the original)

1. Shading data stored in CONTROL

board is not proper to perform an

image process.

1. Perform the

"Shading"

in Sec. 9.3.7 to over-write new data.

2. The dust exists on the Scanning

Glass ((F) or (B)) or its surrounding

(Reference area or others).

1. Wipe off the dust with the roller cleaning paper.

3. Problem with Pixel data from CCD

Board (F) or from image processing

circuit

1. Check the connection and soldering condition of the

following parts.

(1) between CN2001 (CCD Board (F)) and CN1001

(CONTROL Board)

2. Check the soldering condition of the following parts and their

surrounding circuit on the CCD Board (F).

(1) IC2002

(2) IC2003

3. Check the soldering condition of the following parts and their

surrounding circuit on the CONTROL Board.

(1) IC1007 (Gate Array: especially 68th to 71st pins)

(2) IC1004, IC1005 (A/D Conv.)

4. Monitor the following CCD Timing signals on the CN1001.

(1) FCCD_TG: See Fig. 10.1.1.

(2) FCCD_CLK1: See Fig. 10.1.2.

(3) FCCD RS: See Fig. 10.1.3.

(4) FCCD CP: See Fig. 10.1.4.

5. Replace faulty parts or boards.

4. Problem with Pixel data from CCD

Board (B) or from image processing

circuit

1. Check the connection and soldering condition of the

following parts.

(1) between CN2501 (CCD Board (B)) and CN1002

(CONTROL Board)

2. Check the soldering condition of the following parts and their

surrounding circuit on the CCD Board (B).

(1) IC2502

(2) IC2503

3. Check the soldering condition of the following parts and their

surrounding circuit on the CONTROL Board.

(1) IC1007

(Gate Array: especially 73rd, 74th, 79th, and 80th pins)

(2) IC1004, IC1005 (A/D Conv.)

4. Monitor the following CCD Timing signals on the CN1001.

(1) BCCD_TG: See Fig. 10.1.5.

(2) BCCD_CLK1: See Fig. 10.1.6.

(3) BCCD RS: See Fig. 10.1.7.

(4) BCCD CP: See Fig. 10.1.8.

5. Replace faulty parts or boards.

5. Lamp gets dark, or has almost

reached its life expectancy.

(only in case of a darker image.)

1. Perform the

"CCD Level"

test in Sec. 9.3.6 to check the

peak level.

2. Replace an applicable lamp. (Lamp (F) or Lamp (B))

6. Lamp drive circuit (for Front) does

not work properly.

(only in case of darker image)

1. Perform the

"CCD Level"

test in Sec. 9.3.6 to check the

peak level.

2. Check the Lamp Drive Board (F)'s soldering condition and

connection to the Lamp (F).

3. Replace the Lamp Drive Board (F).

7. Lamp drive circuit (for Back) does

not work properly.

(only in case of darker image)

1. Perform the

"CCD Level"

test in Sec. 9.3.6 to check the

peak level.

2. Check the Lamp Drive Board (B)'s soldering condition and

connection to the Lamp (B).

3. Replace the Lamp Drive Board (B).

Symptom

Possible Cause

Check Point

Remarks

Summary of Contents for KV-S1025C SERIES

Page 10: ...10 ...

Page 28: ...28 ...

Page 41: ...41 8 Remove the screw c and the screw d And pull out the Conveyor Motor ...

Page 62: ...62 ...

Page 78: ...78 Fig 10 1 1 Fig 10 1 2 Fig 10 1 3 Fig 10 1 4 Fig 10 1 5 Fig 10 1 6 ...

Page 79: ...79 Fig 10 1 7 Fig 10 1 8 ...

Page 85: ...85 Fig 10 2 5 Fig 10 2 6 Fig 10 2 7 Fig 10 2 8 Fig 10 2 9 ...

Page 86: ...86 ...

Page 89: ...89 11 3 Block Diagram 3 ...

Page 95: ...95 5 2 CONTROL Board KV S1025C Series KV S1020C Series ...

Page 96: ...96 5 3 CONTROL Board KV S1025C Series KV S1020C Series ...

Page 97: ...97 5 4 CONTROL Board KV S1025C Series KV S1020C Series ...

Page 102: ...102 ...

Page 104: ...104 13 1 CONTROL Board 13 1 1 Front Side PbF stamp ...

Page 105: ...105 13 1 2 Back Side ...

Page 109: ...109 14 Parts Location and Mechanical Parts List ...

Page 110: ...110 14 1 Exterior and Chassis ...