54

Replacing Consumable Roller Modules

6

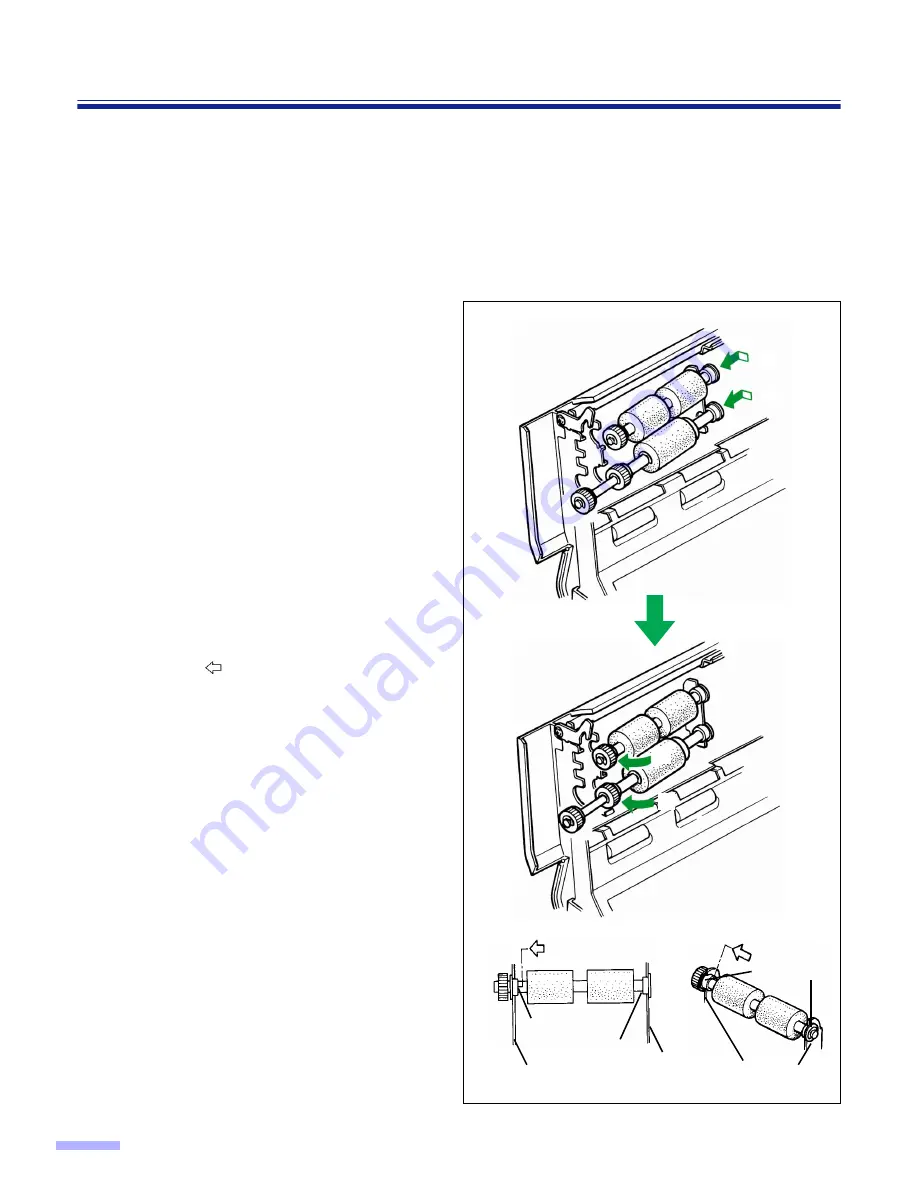

Open the optional “Roller Exchange

Kit (KV-SS044)”, and take out the

paper feed roller module and

separation roller module.

For supplies and accessories:

Call 1-800-346-4768 (U.S.A. only) or

your dealer.

7

Install the new paper feed roller

module and separation roller module

with the gears on the left side and the

post-gear side bearing slide into the

right side guide grooves of the chassis

in the scanner. (

1

)

Then push up the gear side bearings

and install into the left side guide

grooves of the chassis in the scanner.

When installing the second one, it

clicks into place. (

2

)

•

Match the paper feed roller module and

separation roller module with the

bearings and guide grooves, and then

attach them.

When attaching the paper feed roller

module and separation roller module,

push each bearing in the direction of the

arrow and

attach.

•

When attaching the paper feed roller

module and separation roller module to

the chassis, do not damage the rollers.

1

1

2

2

Chassis

Bearing

Bearing

Chassis

Chassises

Bearings