Summary of Contents for KV-SS080

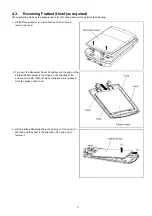

Page 7: ...7 3 COMPONENT IDENTIFICATION 3 1 Part Names ...

Page 8: ...8 3 2 Scanner Status ...

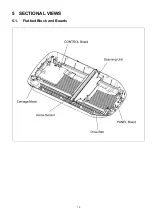

Page 15: ...15 5 SECTIONAL VIEWS 5 1 Flatbed Block and Boards ...

Page 44: ...44 11 2 Block Diagram 2 Board ...

Page 47: ...47 12 PARTS LOCATION AND MECHANICAL PARTS LIST ...

Page 48: ...48 12 1 Main Body ...

Page 50: ...50 12 2 Packing ...