|

66

|

KX-F680BX/KX-F2681BX

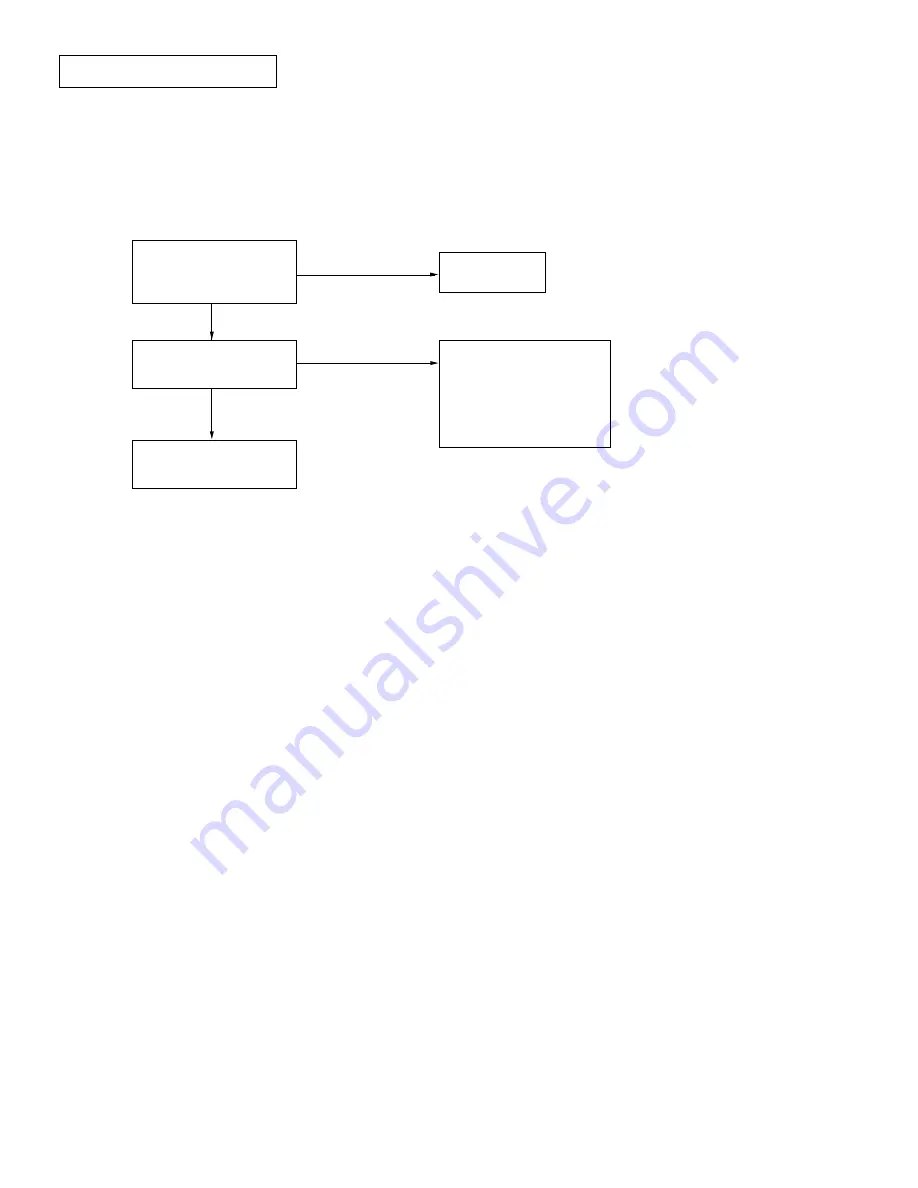

(6) CHECK FLASH MEMORY

If the unit is working correctly but VOICE GUIDANCE (voice prompt) is not heard.

You should check the Flash Memory.

Check Voice prompt

(Service code : 784)

END

Check soldering.

Replace IC1 and IC4.

NG

OK

CAUTION:

The voice promptdata is entered after IC4 is installed on the P.C.Board. If the IC4 is replace, it is necessary to enter the

voice prompt again.

How to enter the voice prompt data

@

Exchange the ROM (IC2) with ROM for service (Ref No. EC23) on the P.C.board.

A

Power ON

B

LCD : "FORMAT"

¤

"ERASE"

¤

"WRITING"

¤

"WRITE OK" (about 15 second)

C

Power OFF

D

Replace the ROM (IC2) with the ROM for service on the P.C.Board.

E

Use #784 and confirm the voice prompt.

Check soldering point

IC1: pin12, pin13, pin106,

pin107, pin108,

pin120

IC4, R63,R64

Summary of Contents for KX-F680BX

Page 1: ......

Page 11: ......

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 127: ......

Page 128: ......

Page 129: ......

Page 130: ... 165 KX F680BX KX F2681BX EC1 EC2 EC3 EC4 EC5 EC6 EC7 EC9 EC10 EC11 EC12 EC13 EC8 TOOLS ...

Page 131: ......

Page 133: ......

Page 134: ......

Page 135: ......

Page 136: ......