Page 15

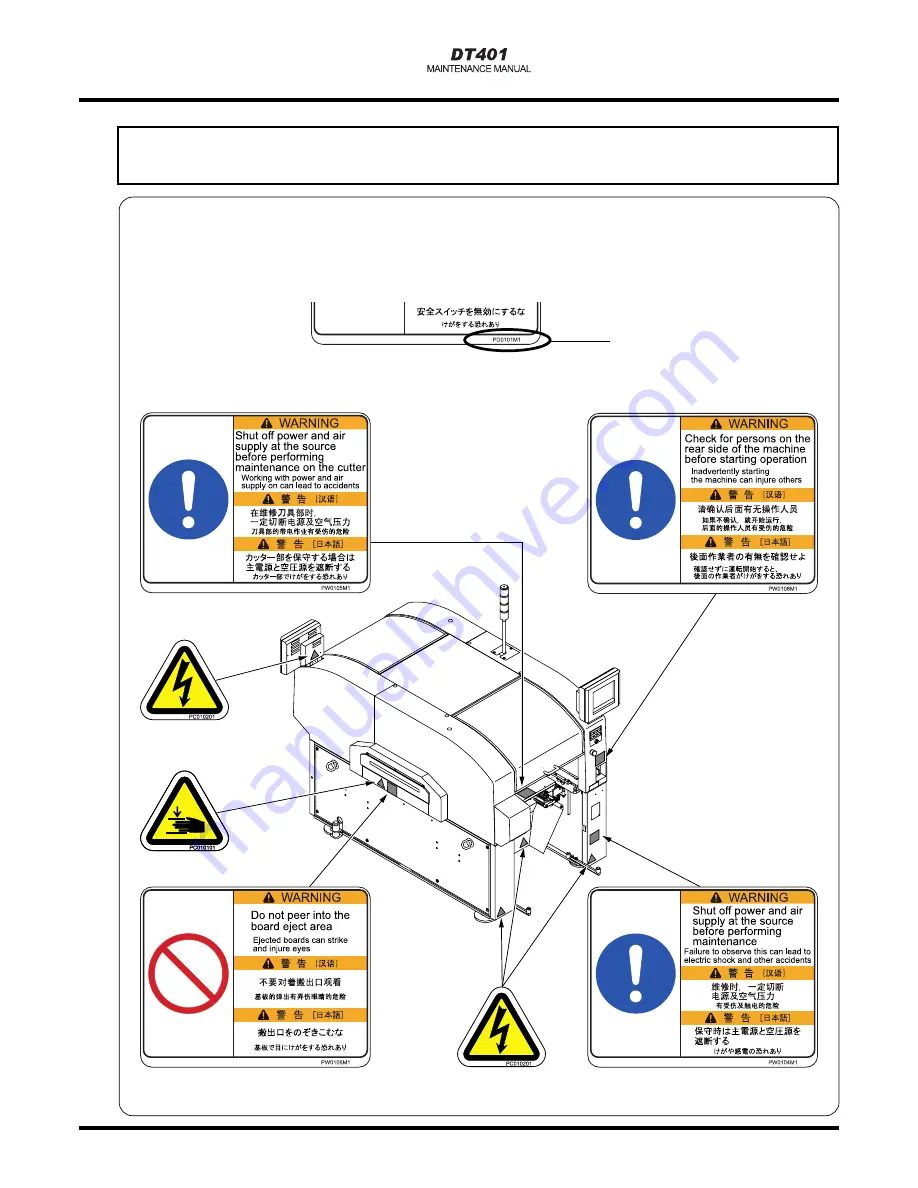

Labels pasted on product for safety

Warning labels

The warning labels are pasted on this machine as follows.

Follow the instructions on each label.

If it has come off, place an order with us for it, referring to the Parts List; then, put a new one on a proper

location.

Label No.

Warning label locations on the front side

E64C-003E

E64C-E-XXA00-A04-01

Summary of Contents for KXF-E64C

Page 2: ......

Page 12: ...10 MEMO E64C E MMA00 A02 00 ...

Page 14: ...Page 2 DANGER E64C E XXA00 A03 01 ...

Page 21: ...Page 9 WARNING E64C E XXA00 A03 01 ...

Page 22: ...Page 10 WARNING E64C E XXA00 A03 00 ...

Page 23: ...Page 11 WARNING E64C E XXA00 A03 00 ...

Page 24: ...Page 12 CAUTION E64C E XXA00 A03 00 ...