LK-T

3

ds_61113_0004_en_lkt: 091008J

NOTES

For Cautions for Use, see

Relay Technical Information

.

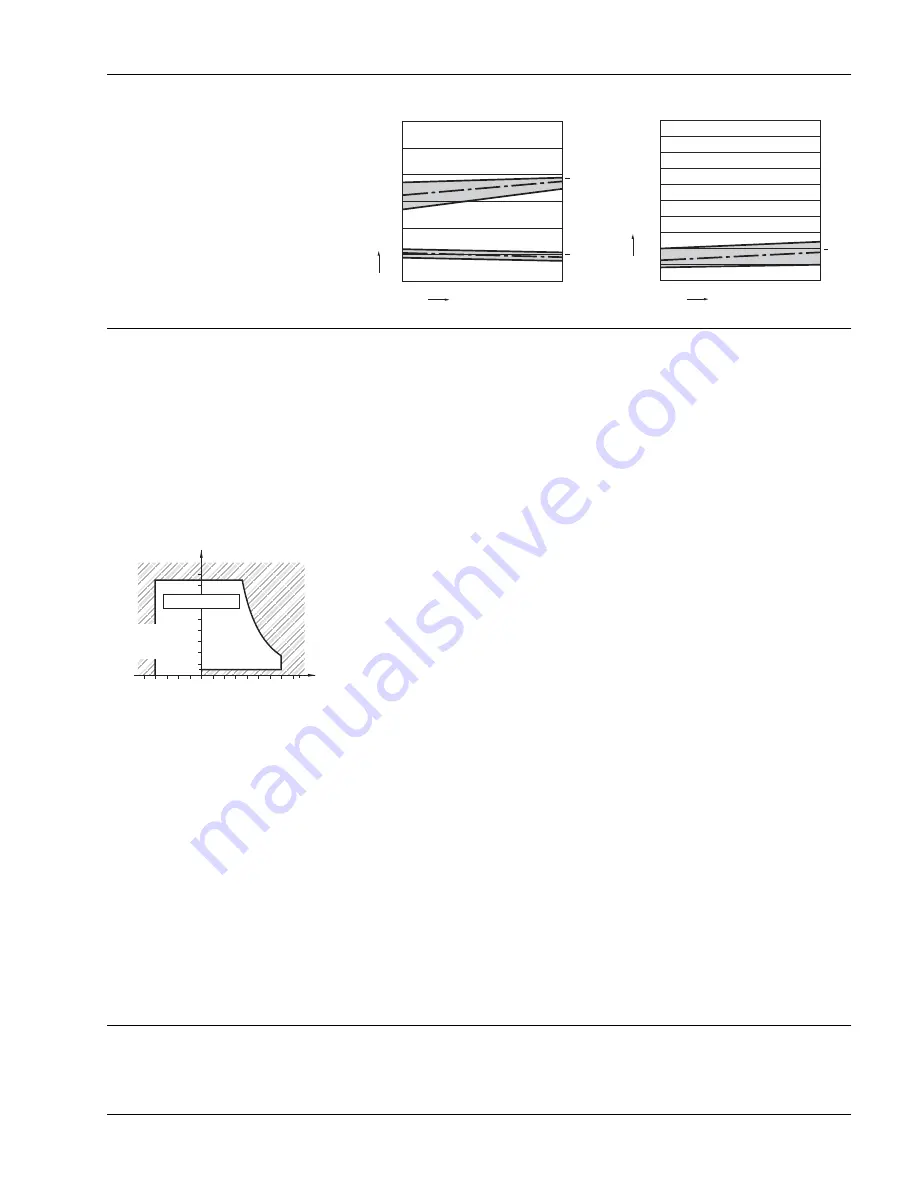

4-(2). Electrical life test

(UL508 TV-8 rating test)

Sample: LKT1aF-12V, 6 pcs.

• Overload test

Load: 12 A 120 V AC (60 Hz),

Inductive load (cos

φ

= 0.75)

Operation frequency: 6 times/min

(ON : OFF = 1 s : 9 s)

No. of operations: 50 ope.

• Endurance test

Load: 8A 120 V AC (960 W lamp load),

(Inrush: 118 A)

Operation frequency: 1 times/min

(ON: OFF = 1 s: 59 s)

No. of operations: 25,000 ope.

Change of pick-up and drop-out voltage

Change of contact resistance

0

25

0

2

4

6

8

10

12

Drop-out voltage

Pick-up voltage

Max.

Min.

x

No. of operations,

×

10

3

Pick-up and drop-out voltage, V

Max.

Min.

x

0

0

5

10

15

20

25

30

35

40

45

50

25

Max.

Min.

x

No. of operations,

×

10

3

Contact resistance, m

Ω

1. Usage, transport and storage

conditions

1) Temperature:

–40 to +70

°

C

–40 to +158

°

F

2) Humidity: 5 to 85% RH

(Avoid freezing and condensation.)

The humidity range varies with the

temperature. Use within the range

indicated in the graph below.

3) Atmospheric pressure: 86 to 106 kPa

Temperature and humidity range for

usage, transport, and storage

4) Condensation

Condensation forms when there is a

sudden change in temperature under

high temperature and high humidity

conditions. Condensation will cause

deterioration of the relay insulation.

5) Freezing

Condensation or other moisture may

freeze on the relay when the

temperatures is lower than 0

°

C

32

°

F

.

This causes problems such as sticking of

movable parts or operational time lags.

6) Low temperature, low humidity

environments

The plastic becomes brittle if the relay is

exposed to a low temperature, low

humidity environment for long periods of

time.

2. Solder and cleaning conditions

1) Please obey the following conditions

when soldering automatically.

(1) Preheating: Within 120

°

C

248

°

F

(solder surface terminal portion) and

within 120 seconds

(2) Soldering iron: 260

°

C

±

5

°

C

500

°

F

±

41

°

F

(solder temperature) and

within 6 seconds (soldering time)

2) Since this is not a sealed type relay, do

not clean it as is. Also, be careful not to

allow flux to overflow above the PC board

or enter the inside of the relay.

3. Certification

1) This relay is UL and C-UL certified

(File No. E43149).

UL, C-UL rating: TV-8

2) This relay is certified by TUV as an

electromagnetic relay that complies with

VDE0435 (File No. B040413461035).

(1) TUV rating: 8A, 250 V to COS

φ

= 1.0

(2) The terminals of this relay can only be

connected with solder.

(3) This relay is certified by SEMKO (File

No. 400968).

SEMKO rating: 3/100A 250 V AC, 5/40A

250 V AC

4. Others

1) For precautions regarding use and

explanations of technical terminology,

please refer to “Relay Technical

Information”.

2) To ensure good operation, please keep

the voltage on the coil ends to

±

5% (at

20

°

C

68

°

F

) of the rated coil operation

voltage. Also, please be aware that the

pick-up voltage and drop-out voltage may

change depending on the temperature

and conditions of use.

3) Keep the ripple rate of the nominal coil

voltage below 5%.

4) The cycle lifetime is defined under the

standard test condition specified in the

JIS* C 5442 standard (temperature 15 to

35

°

C

59 to 95

°

F

, humidity 25 to 75%).

Check this with the real device as it is

affected by coil driving circuit, load type,

activation frequency, activation

phase,ambient conditions and other

factors.

Also, be especially careful of loads such

as those listed below.

(1) When used for AC load-operating and

the operating phase is synchronous.

Rocking and fusing can easily occur due

to contact shifting.

(2) High-frequency load-operating

When high-frequency opening and

closing of the relay is performed with a

load that causes arcs at the contacts,

nitrogen and oxygen in the air is fused by

the arc energy and HNO

3

is formed. This

can corrode metal materials.

Three countermeasures for these are

listed here.

• Incorporate an arc-extinguishing circuit.

• Lower the operating frequency

• Lower the ambient humidity

5) Heat, smoke, and even a fire may

occur if the relay is used in conditions

outside of the allowable ranges for the

coil ratings, contact ratings, operating

cycle lifetime, and other specifications.

Therefore, do not use the relay if these

ratings are exceeded.

6) If the relay has been dropped, the

appearance and characteristics should

always be checked before use.

7) Incorrect wiring may cause

unexpected events or the generation of

heat or flames.

Humidity, %RH

Tolerance range

85

5

0

70

-40

+32

+158

-40

Temperature,

°

C

°

F

(Avoid freezing

when used at

temperatures lower

than 0

°

C

(Avoid

condensation

when used at

temperatures higher

than 0

°

C

32

°

F

)

32

°

F

)