188

5-1

Troubleshooting

If any operation errors occur, check items below first.

When the problems cannot be resolved by following the below measures, please contact us.

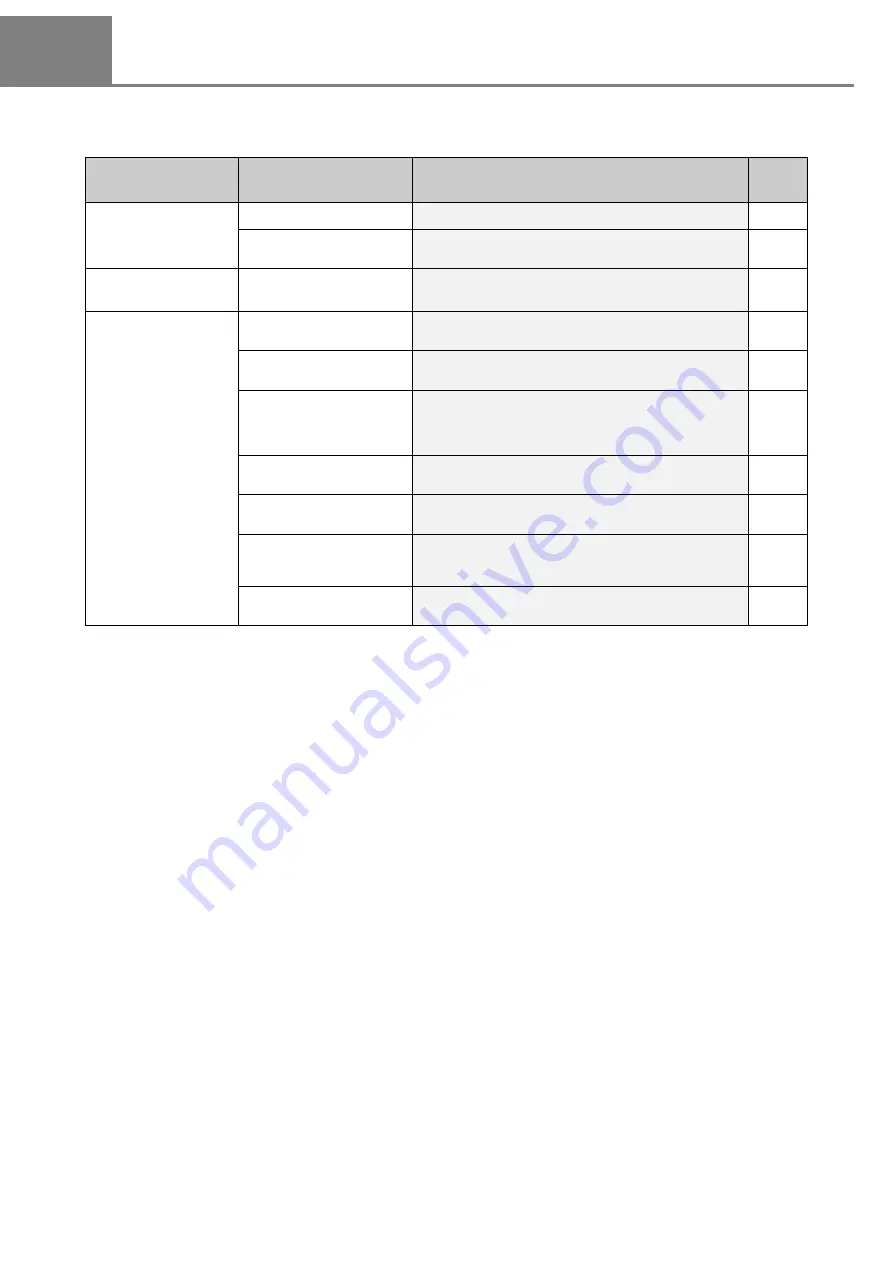

Troubles

Possible Causes

Measures

Ref.

Page

Power supply is not

turned on.

Power cable is not connected.

Connect the power cable.

Power cable is not plugged

in outlet

Insert the plug in the socket.

The guide laser does

not light.

The shutter lever is not set

to the guide laser side.

Set the shutter lever to the guide laser side.

Data cannot be

marked.

The marking start command

is not input.

Input the marking start command.

-

The distance to the work

has not been calibrated.

Calibrate the distance to the work.

Laser power and scan

speed are not appropriate

to the marking target

object.

Raise the laser power or lower the scan speed. Or

perform both of them.

The trigger signal is kept

ON.

Since the trigger signal sensitive to the edge, input the

edge.

The manual shutter is

closed (in remote mode).

Open the manual shutter.

The laser radiation stop

input of the I/O connector

is OFF.

Turn ON the laser radiation stop input from the I/O

connector.

The interlock of the power

supply BOX is removed.

Attach the optional interlock connector.

Summary of Contents for LP-310

Page 5: ...5 MEMO ...

Page 21: ...21 MEMO ...

Page 26: ...26 MEMO ...

Page 30: ...30 MEMO ...

Page 33: ...33 MEMO ...

Page 87: ...87 MEMO ...

Page 125: ...125 MEMO ...

Page 137: ...137 MEMO ...

Page 149: ...149 MEMO ...

Page 155: ...155 4 External Control 4 1 Control Through I O Connector 156 4 2 Control with RS 232C 166 ...

Page 186: ...186 MEMO ...

Page 187: ...187 5 Troubleshooting 5 1 Troubleshooting 188 5 2 Measures for Indicated Error 189 ...

Page 191: ...191 6 Maintenance 6 1 Maintenance 192 ...

Page 193: ...193 7 Specification 7 1 Specification 194 7 2 Outer Dimensional Drawing 195 ...

Page 197: ...197 Appendix Character Code Table 198 Readable DXF File 207 Glossary 209 ...

Page 212: ...212 Index Index 213 ...

Page 215: ...No 9000 0062 20V ...